Software & System

In sophisticated and complex systems, it is necessary to link and control multiple parts, with system technology optimizing the behavior of each part for the product’s function. Generally, this control is performed using electrical signals, and software technology for designing and implementing control programs is essential.

Nikon's optical instruments also convert light information into electrical signals and use them to control drive systems and other devices. In design and manufacturing, software technologies such as modeling the target system and predicting potential phenomena through calculations (simulations) also support Nikon’s advanced manufacturing.

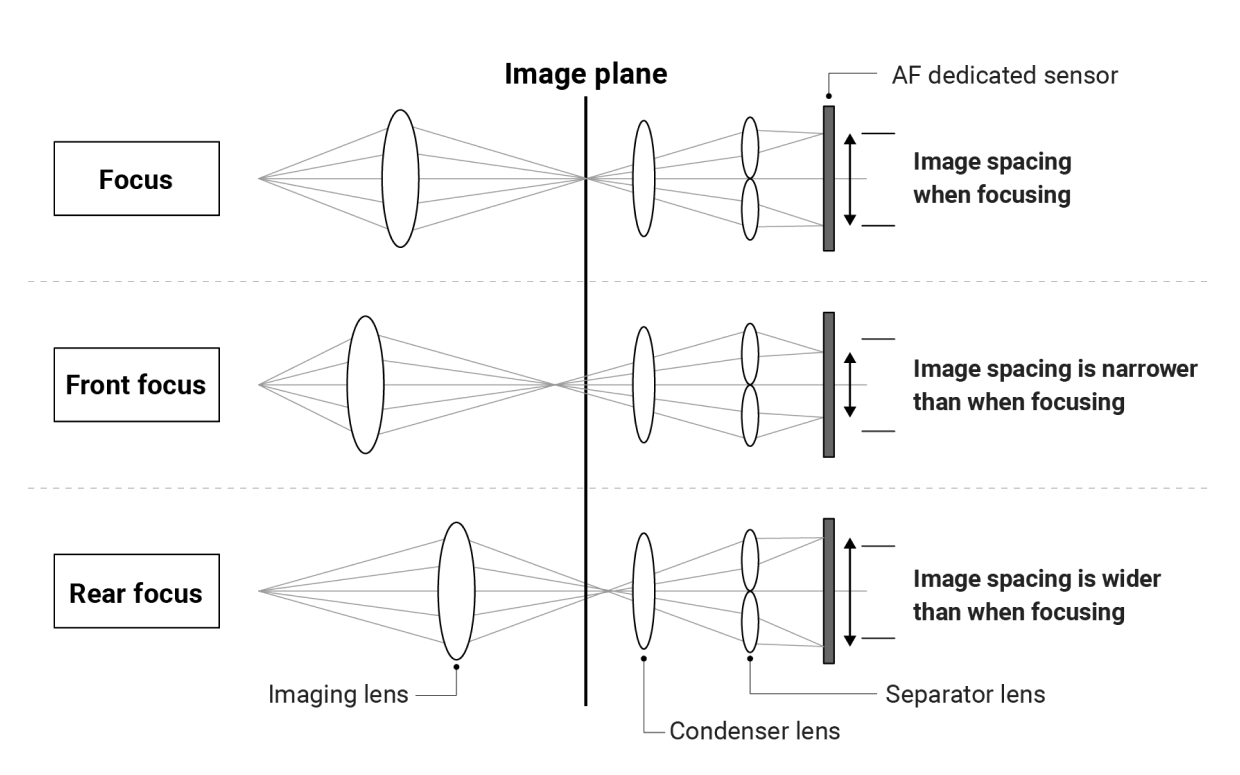

AF System

The autofocus (AF) system, which automatically focuses on the subject, not only simplifies focusing for cameras but also enables precise automatic measurements in industrial applications. This technology is essential for cameras to follow fast-moving objects and for lithography systems to consistently and faithfully project circuit patterns onto fast-moving wafer surface.

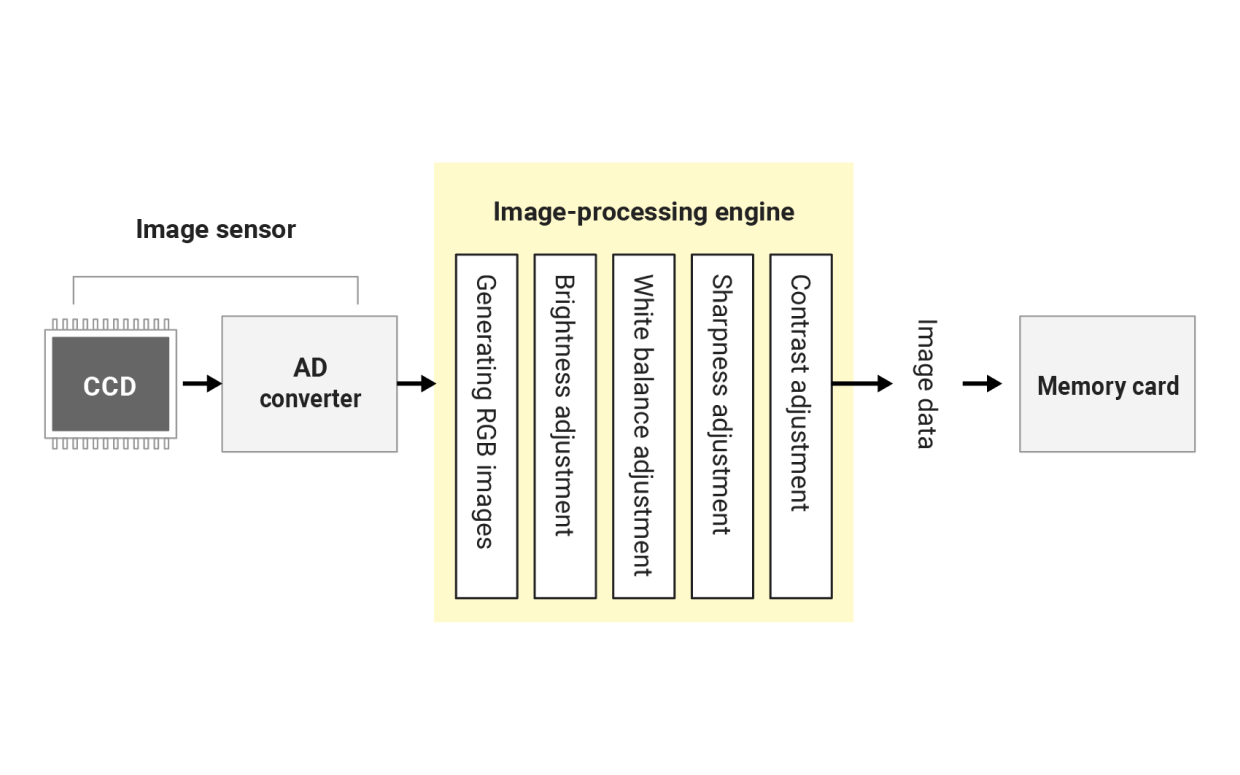

Image-Processing Engine

The image-processing engine, a computing device dedicated to image processing, quickly converts the electrical signals obtained from the image sensor into image data and outputs it. It plays an important role in adjusting colors, brightness, and contrast. Nikon designs efficient algorithms for cameras to process the large amount of data that comes with higher resolutions at high speed and with low power consumption.

High-Precision Stage Control

In measuring and processing machines, the target object is placed on the stage, and the desired location can be measured and processed by accurately driving it according to the drive command amount. High-precision, high-speed control enables fast and accurate measurement and processing, leading to high-quality manufacturing and improved productivity in industrial products.

At Nikon, high-speed, high-precision control of the stages on which wafers and samples are placed is important for measuring machines, optical processing machines, lithography systems, and microscopes.

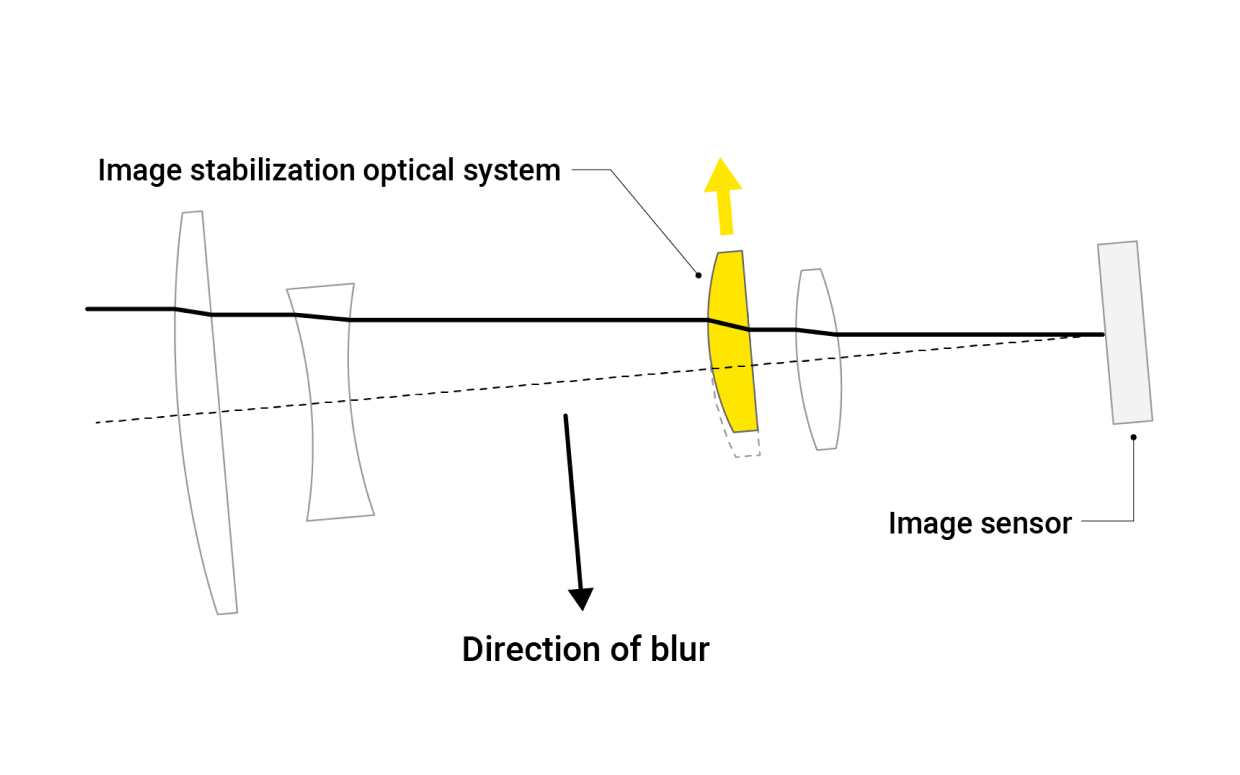

Image Stabilization

By compensating for the effects of camera shake when taking pictures, you can obtain clear and sharp images. This is particularly effective in low-light situations, such as night scenes and indoors, where camera shake is more likely to occur, and with telephoto lenses, expanding the possibilities for handheld shooting. When using a telephoto lens, which requires a larger correction range, corrections are performed both in the lens and in the camera. In the brief moment when the shutter is pressed, camera shake must be detected and the optical system and image sensor quickly adjusted.

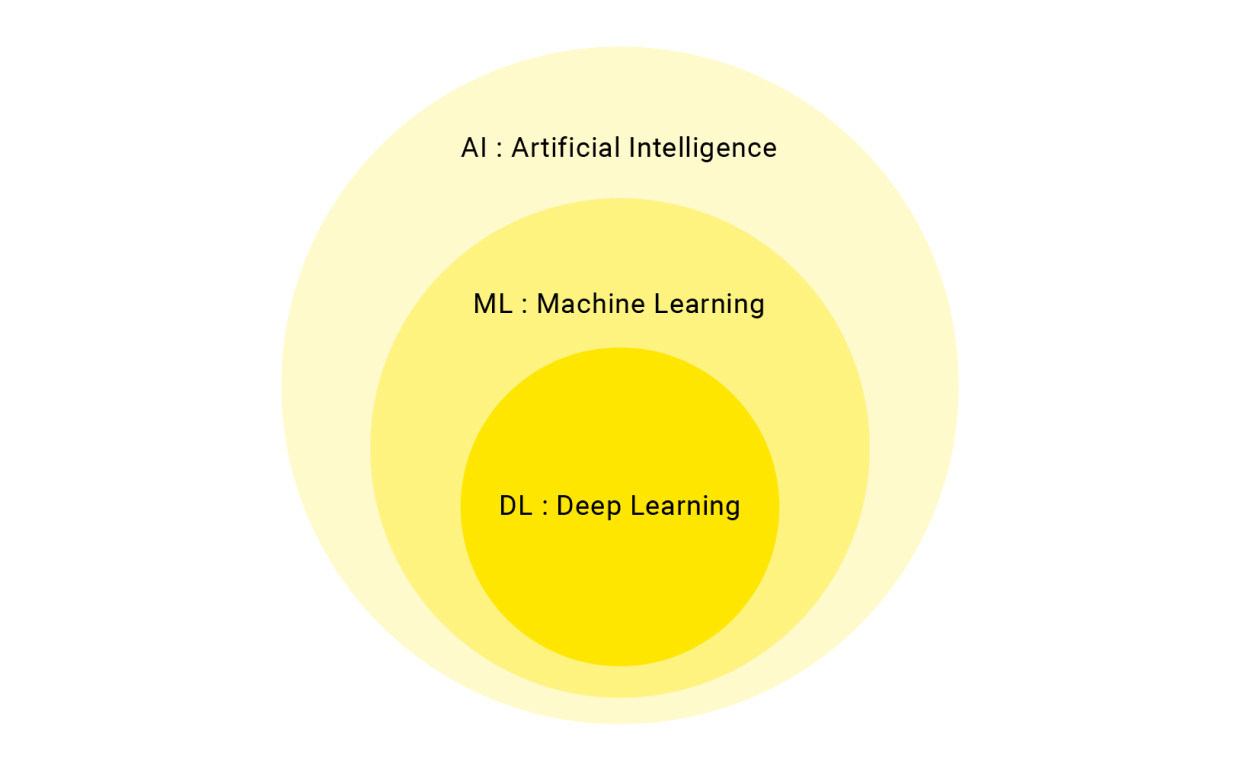

Deep Learning

Deep learning, which is a subset of artificial intelligence (AI), is based on models trained with large amounts of data and can perform extensive processing tasks, such as image and voice recognition and natural language processing, under specific conditions.

At Nikon, it is mainly used for subject recognition in cameras and cell detection in microscopes. In industrial applications, it facilitates the detection of minute defects using X-ray CT. Deep learning is compatible with extracting features from images, and we expect to see it applied further in Nikon products.

You can search for articles related to Nikon’s technology, research and development by tag.