Precision Glass Mold

Technology Overview

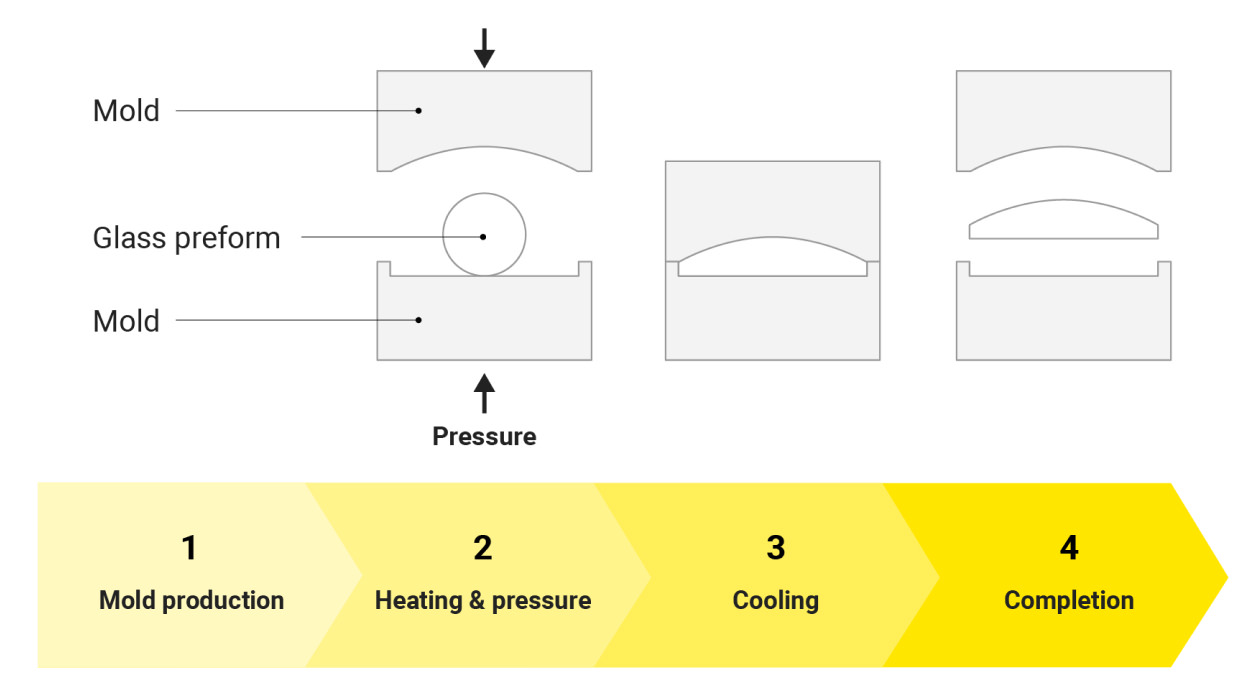

By using a precisely machined carbide mold to pressurize glass that has been softened at high temperatures, it is possible to mass-produce lenses of the same shape without grinding and polishing. In particular, because grinding and polishing aspherical lenses is highly difficult and time-consuming, the fact that by producing a mold with an aspherical shape, they can be mass-produced in the same way as spherical lenses is a major advantage.

The glass material and mold are heated to the required temperature, pressed into shape, and then cooled below the glass transition point. Since the softening temperature (deformation point) and compatibility with mold materials depend on the composition of glass, it is necessary to develop a glass composition that is easy to mold while also taking into account the required optical properties. We also develop molding processes that involve precision machining of molds based on the desired shape, devising coatings to prevent fusion, and precisely controlling temperature and pressure.

This molding process is applied in consumer products, such as camera lenses that require mass production. To ensure that productivity is not compromised when using various glass types, it is necessary to design molds suited to the physical and chemical properties of each glass type.

Glass requires higher temperatures to be molded than resin, and its surface must be polished to a high degree of mirror finish when used in optical components such as lenses. Furthermore, because molding is required under high loads, it is necessary to develop molds and molding processes that allow for mass production in harsh environments. The manufacture of aspherical lenses, which are effective in achieving small and lightweight design, requires complex molding simulations that are not necessary with spherical lenses.

Technology Application Examples

Interchangeable Camera Lenses

Aspherical lenses, which have a non-spherical curved surface, can effectively correct various aberrations, including distortion and spherical aberration. They are particularly effective in controlling distortion, which is a problem with wide-angle lenses. Distortion is an aberration (image distortion) that occurs when the magnification varies depending on the image height (distance from the optical axis on the image plane) when the subject is imaged through a lens. It can be corrected by using an aspherical surface to continuously change the refractive power from the center of the lens to the periphery. In addition, a single aspherical lens can provide the same aberration correction effect as multiple spherical lenses, making it possible to make lenses that are more compact and lightweight than spherical lenses.

Technologies related to these examples

Related Technology

Molding

Molding is the process of using a mold to make a material into a desired shape. Once the mold is made, it is possible to mass produce the same item at low cost. Molding can be used on a wide range of materials, including not only glass but also metals and resins. Generally, the material is softened and shaped by raising the temperature, so a mold is made of a material that will not deform at that temperature is used. The design, processing, and surface treatment of the mold are also important, as they determine the quality of molding. For materials with low melting points, such as resin, we use a method called injection molding, which involves melting the resin, pouring it into a mold, cooling it, and molding it into shape.

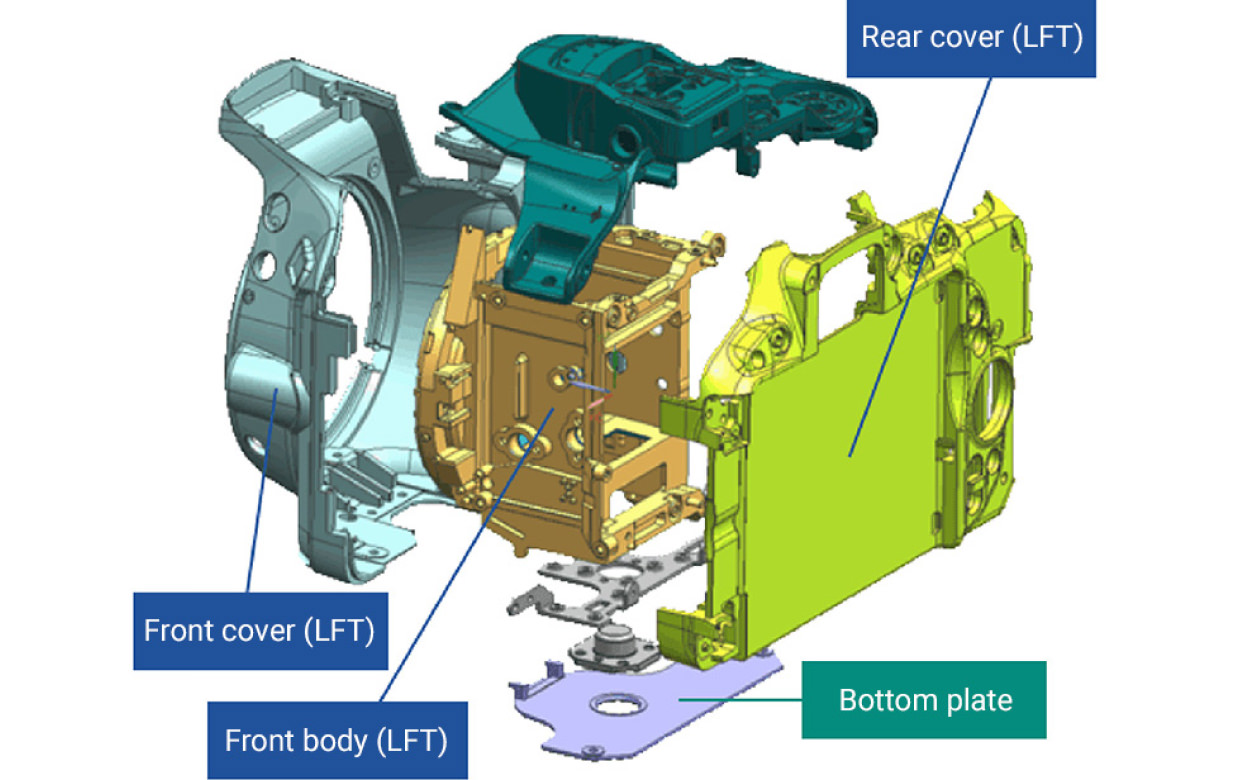

Molding is the most suitable manufacture method for parts that are produced in large quantities, such as camera bodies. Camera bodies that are required to be small and lightweight require complex shapes to be molded in one piece while maintaining strength. The lens barrel (the tube in which the lens is placed) is molded from resin, and the lens barrel must be as perfectly circular as possible so that a circular lens can fit into it. It is important to select materials, design and process molds, and manufacture processes that enable efficient and stable production.

Main Related Products

You can search for articles related to Nikon’s technology, research and development by tag.