Precision Processing

This technology is essential for Nikon’s high-precision components and product assembly. We manufacture a variety of products that differ in production quantity, precision, and size, and we apply processing methods that are suitable for each product. In particular, there are many types of glass and films used for optical systems. These require suitable treatment processes and equipment for the materials and specifications.

High-precision processing of metal is crucial for mechanical components and lens molds. We provide optical processing machines, and we work to support processing not only for our own company but also for our customers.

Aspherical Processing

In optical systems, design freedom is increased by using not only spherical lenses but also aspherical lenses and mirrors, making it possible to achieve desired design specifications. Grinding and polishing processes for aspherical surfaces require more complex processing operations based on the desired shape than for spherical surfaces with uniform curvature. At Nikon, it is applied to the projection lenses of lithography systems, which require the ultimate optical performance, and to binoculars and camera lenses, which need to be smaller and lighter.

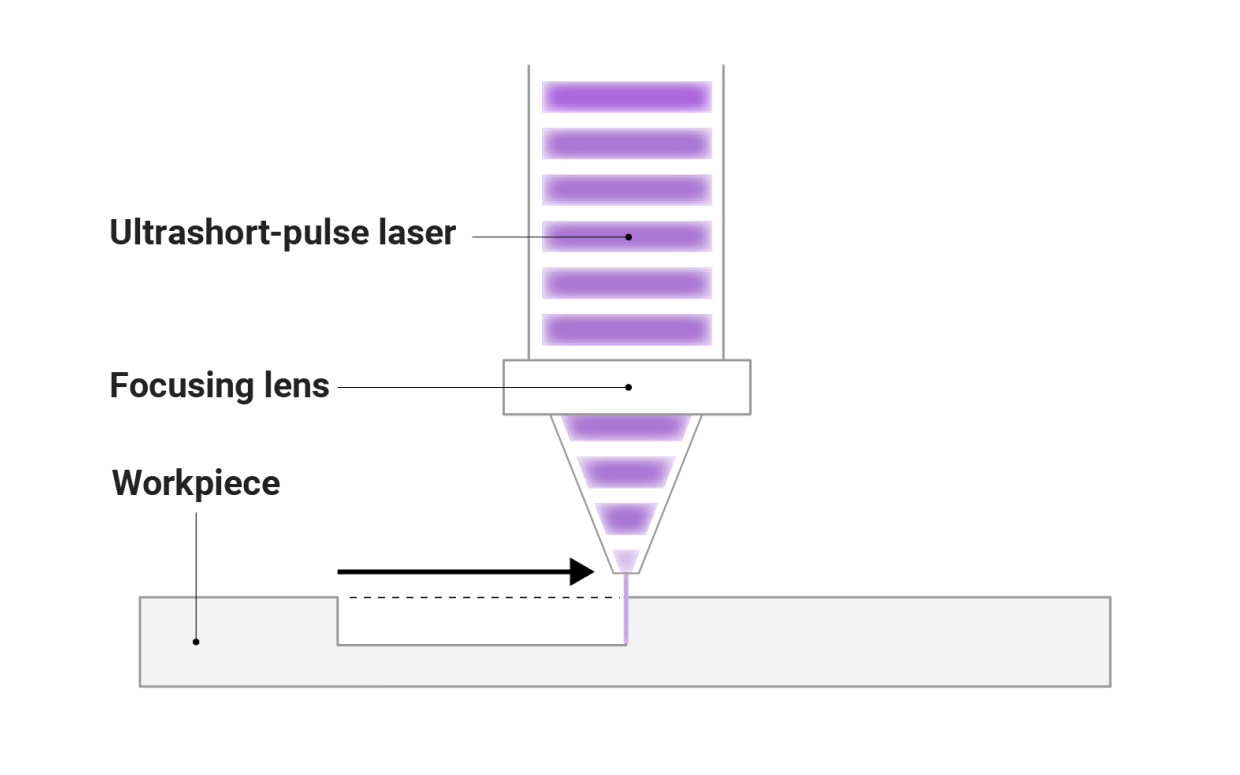

Laser Ablation Processing

This is a processing method that uses a laser to remove material, and can be applied to almost any solid material, including metals, glass, and ceramics. As a non-contact method, it easily processes complex shapes, and it is also possible to process multiple composite parts as one piece. At Nikon, it is used for processing high-precision metal parts with complex shapes and difficult-to-process lens shapes. We provide optical processing machines, and also propose microstructure processing methods such as riblet processing that lead to energy savings.

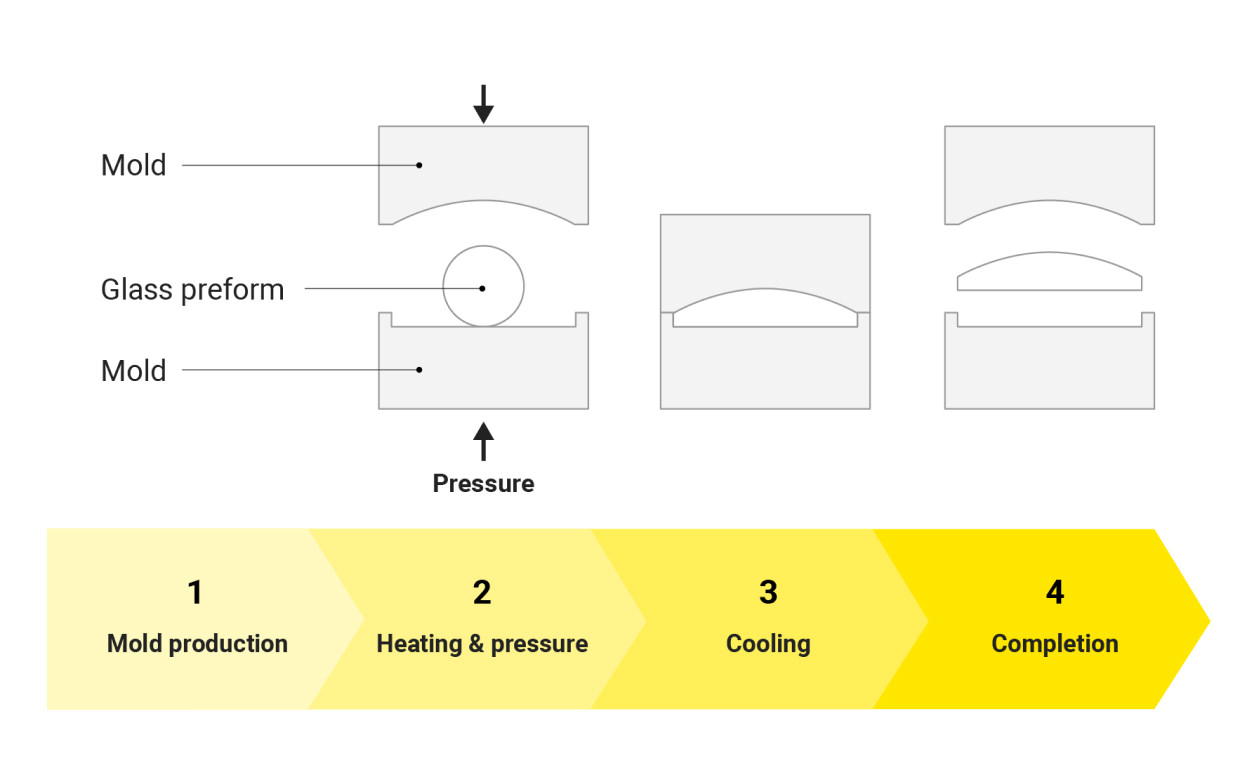

Precision Glass Mold

By using a precisely machined carbide mold to pressurize glass that has been softened at high temperatures, it is possible to mass-produce lenses of the same shape without grinding and polishing. In particular, because grinding and polishing aspherical lenses is highly difficult and time-consuming, the fact that by producing a mold with an aspherical shape, they can be mass-produced in the same way as spherical lenses is a major advantage. Nikon applies it to camera lenses, which are manufactured in large quantities.

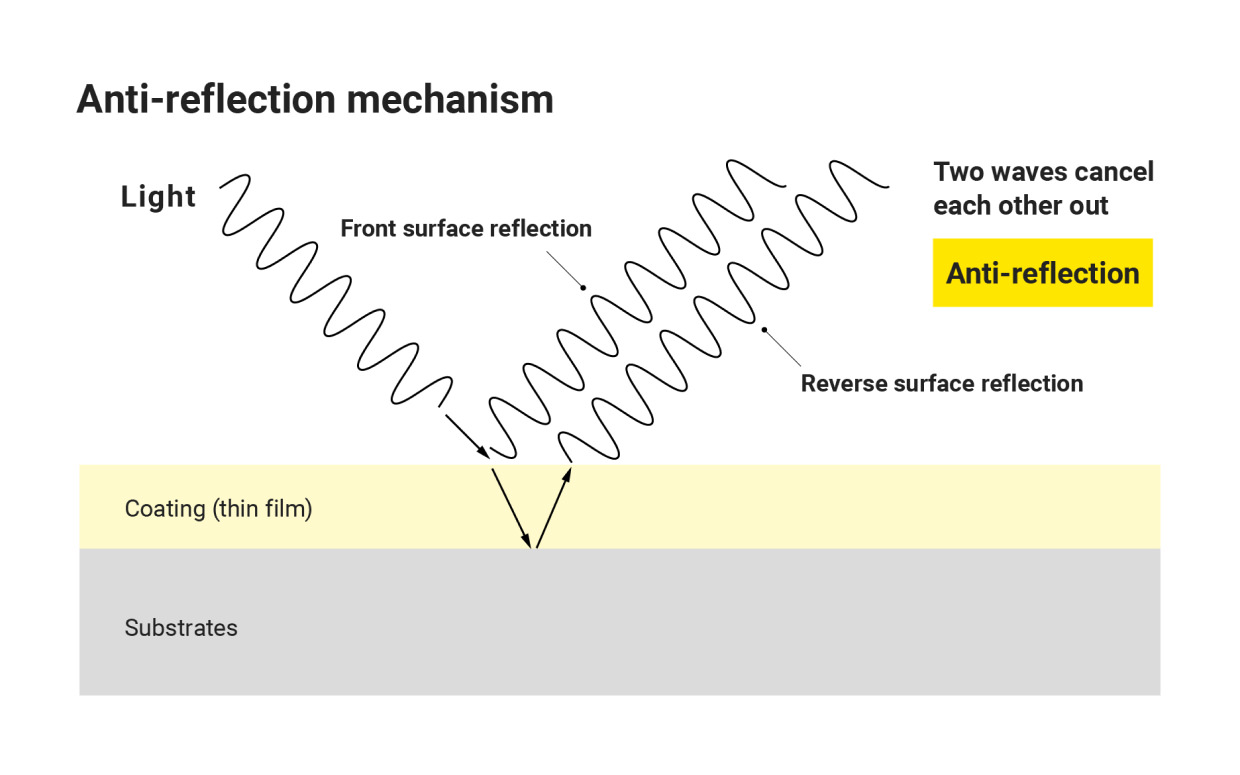

Anti-Reflective Coatings

Anti-reflective coatings reduce surface reflections to make light easier to see. Anti-reflection coatings are formed into multilayer films of materials and thicknesses designed to reduce reflection in the wavelength range of light used. It is essential in optical systems that use many lenses, such as camera lenses, microscope objectives, and projection lenses. The light reflected at the lens interface is reflected multiple times by the lens surfaces, causing ghosts and flares, which can be reduced.

You can search for articles related to Nikon’s technology, research and development by tag.