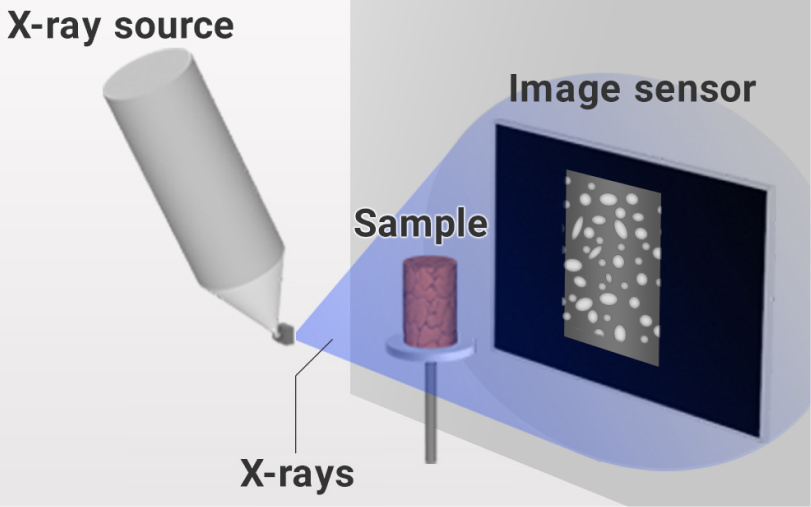

X-ray Source

Technology Overview

X-rays are a type of electromagnetic wave generated from the outer part of an atom’s nucleus and refer to electromagnetic waves with wavelengths much shorter than the wavelength of visible light, which is generally called light. The interaction of electromagnetic waves in such a short wavelength range with matter is different from that of visible light; for example, there are many materials that do not allow visible light to pass through but are permeable to X-rays. In other words, objects that could not be “seen” with visible light can now be “seen” (detected) using X-rays.

X-rays are generated by two principles. One is a phenomenon in which the orbital electrons are irradiated with electrons whose energy is higher than that of the orbital electrons, thereby knocking them out of their orbit, and when outer orbital electrons transition into the empty orbit, energy is released as electromagnetic waves called characteristic X-rays. The other is a phenomenon called bremsstrahlung (braking radiation), where electromagnetic waves are generated when electrons with large kinetic energy are slowed down or deflected due to Coulomb interactions with atomic nuclei.

In so-called X-ray tubes, the above phenomenon is caused by accelerating electrons emitted from an electron source and colliding them with a metal called a target. As an X-ray source, the detail and contrast of the obtained transmission image can be improved by reducing the spot size of the target area where X-rays are emitted and by adjusting the electron acceleration voltage (tube voltage). Increasing the number of electrons irradiated onto heavy metals (tube current) and increasing the tube voltage also leads to an increase in the X-ray dose.

Click to enlarge

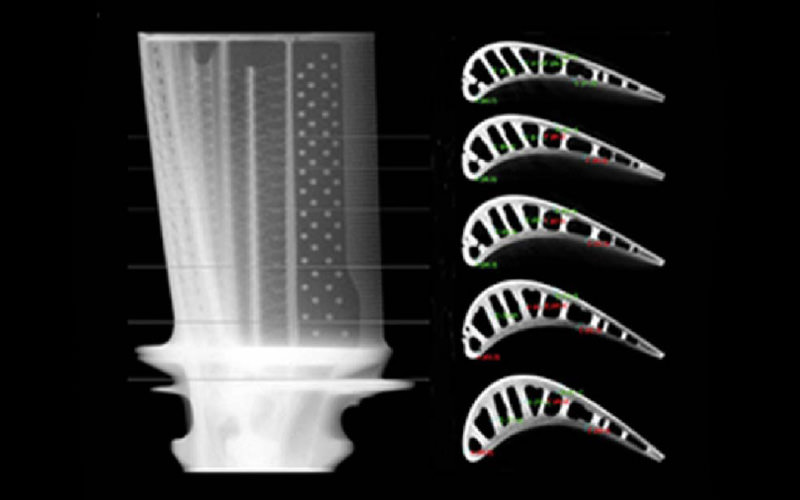

Generally, to observe thicker samples at high speed, it is effective to improve the S/N ratio by increasing X-ray dose. To deliver high-definition images, reducing the X-ray spot size is beneficial. Nikon’s X-ray source improves transmittance with a high tube voltage of 450kV and uses a unique cooling mechanism to suppress thermal damage to the target, achieving both high output and small spot size. Realizing accurate inspections of high-density samples, that had previously been difficult to achieve, the 450kV microfocus X-ray source is now able to ensure effective evaluation of large-sized cast metals and single-crystal-alloy turbine blades.

Technology Application Examples

Industrial X-ray and CT Systems

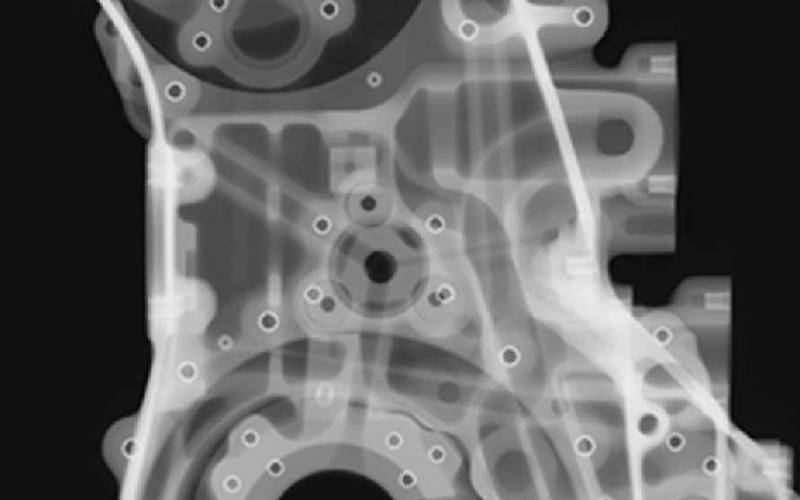

X-ray and CT Systems measures the complex inner structures of products and detects any defects within them, without any disassembly. Nikon’s technology provides high-precision nondestructive inspection support to manufacturers.

The system creates 2D images by capturing the projected X-rays that passes through a sample. For 3D CT (computed tomography) images, sequential 2D images obtained by rotating the sample are reconstructed to generate a 3D volumetric representation.

The resulting images from the system enable nondestructive evaluation of diverse products, ranging from electronic components to plastic molds and cast metals. In addition to supporting manufacturing and inspection processes, applications extend to academic research, such as in excavations searching for minerals and fossils, as well as archaeological investigations.

Technologies related to these examples

Related Technology

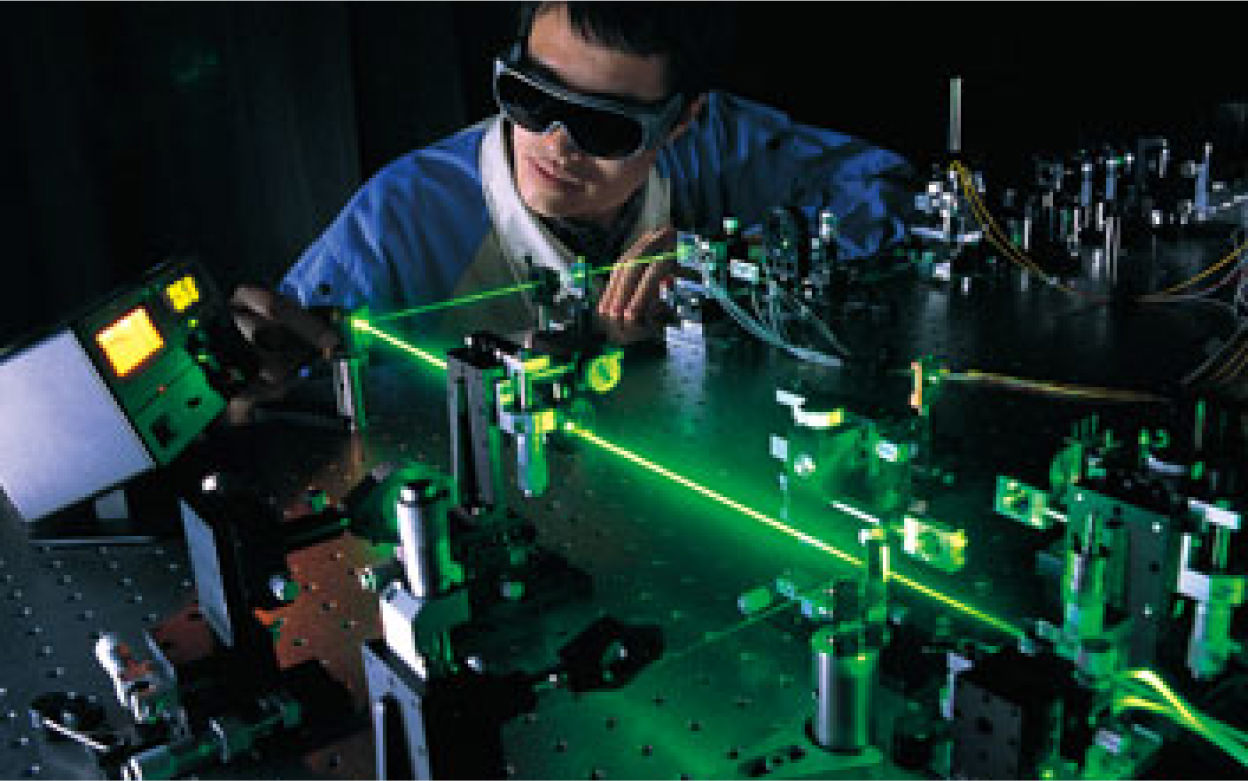

Light Sources

A light source is a starting point for an optical instrument. For example, optical measurement equipment irradiates an object with light from the light source and obtains information, such as the object’s position and physical properties, from the light reflected and scattered by the object. Therefore, light sources are important because the measurement accuracy and the objects that can be measured vary depending on the light from the light source. Light has various characteristics, not only wavelength and intensity, but also its temporal change, coherence, and polarization. It is necessary to emit and control these characteristics in a more desired state.

Nikon is developing light sources in special wavelength ranges, such as solid-state lasers in the deep ultraviolet region and X-ray sources.

Solid-state lasers in the deep ultraviolet region, used for measurements, protein crystal processing, and other applications, require high output, stability, and a high repetition rate. It is necessary to amplify infrared light and efficiently convert them to shorter wavelengths using a wavelength conversion element.

Main Related Products

You can search for articles related to Nikon’s technology, research and development by tag.