Spectral Imaging

Technology Overview

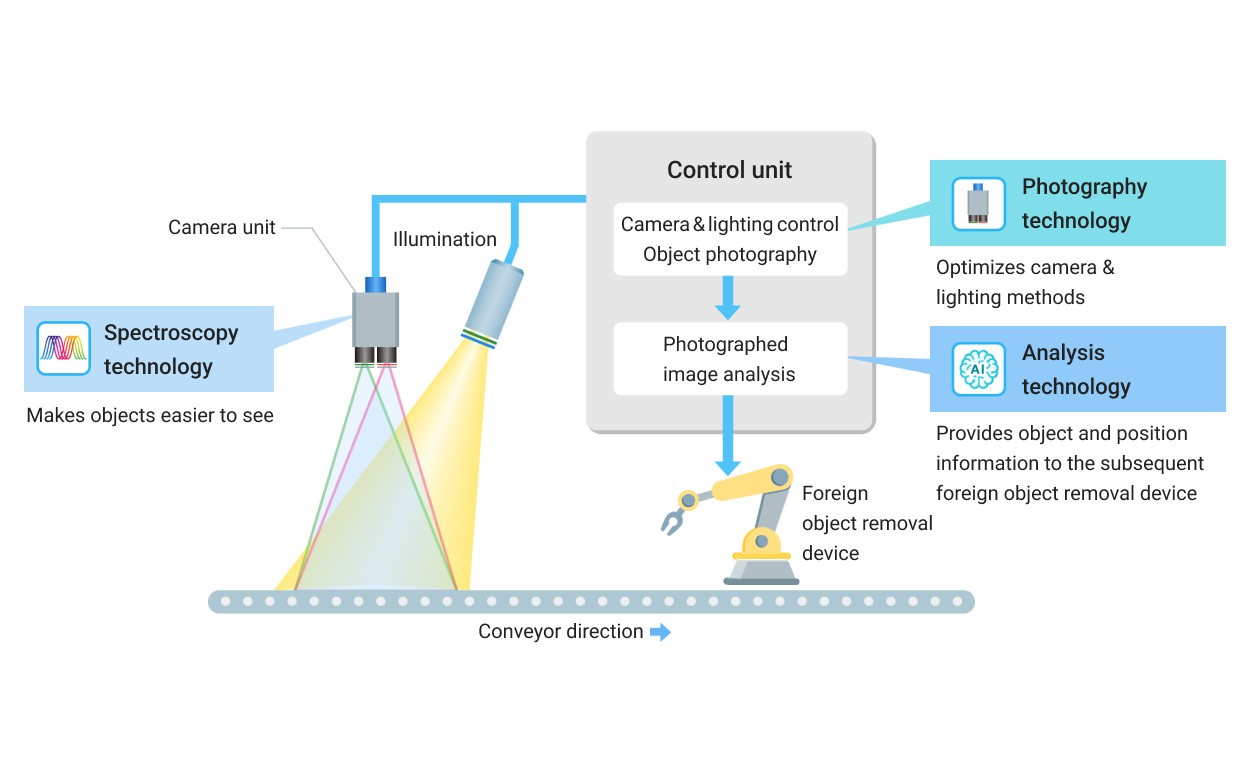

Materials vary in their degree of transmission and reflection depending on the wavelength of light, allowing the identification of substances using this property. Spectral imaging enables the understanding of the spatial distribution of materials. It is commonly used with ultraviolet, visible, and near-infrared wavelengths to identify organic substances. For example, it is used in detecting abnormalities in biological tissues and for quality control in food products. Since it primarily uses visible light, its non-invasive nature is also an advantage.

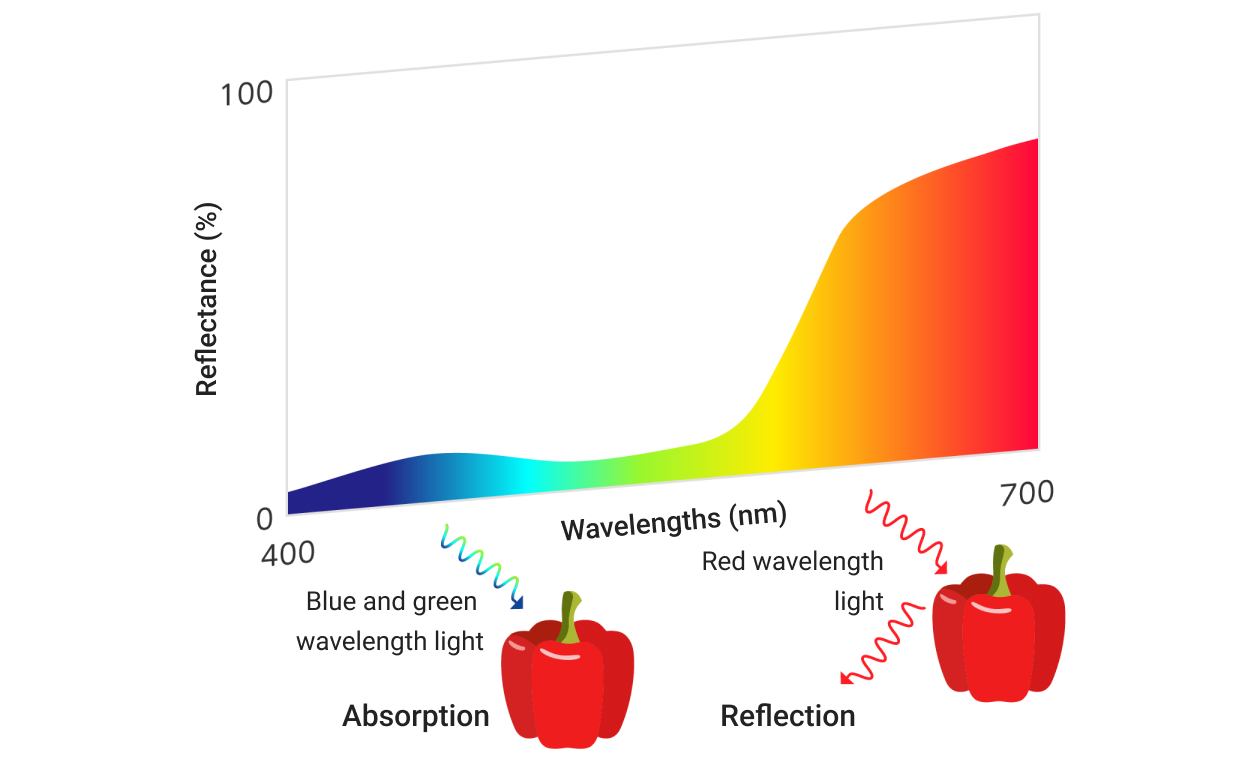

The existence of “light” is essential to seeing things. We see objects by capturing the light reflected from them with our eyes. That light contains various wavelengths, and we perceive the differences in wavelength of light reflected by objects as “colors.” The separation of light into components of each wavelength is called “spectroscopy.” The figure shows a graph of the distribution of light intensity for each wavelength component by spectrally reflecting light from the bell pepper. You can see that it reflects a lot of red light (light with long wavelengths) and absorbs other light.The wavelengths of light that are reflected and those that are absorbed (spectral reflectance characteristics) differ depending on the material and its quantity in the object. Spectroscopy measures the spectral reflectance characteristics of each object and can be applied to a variety of fields.

Click to enlarge

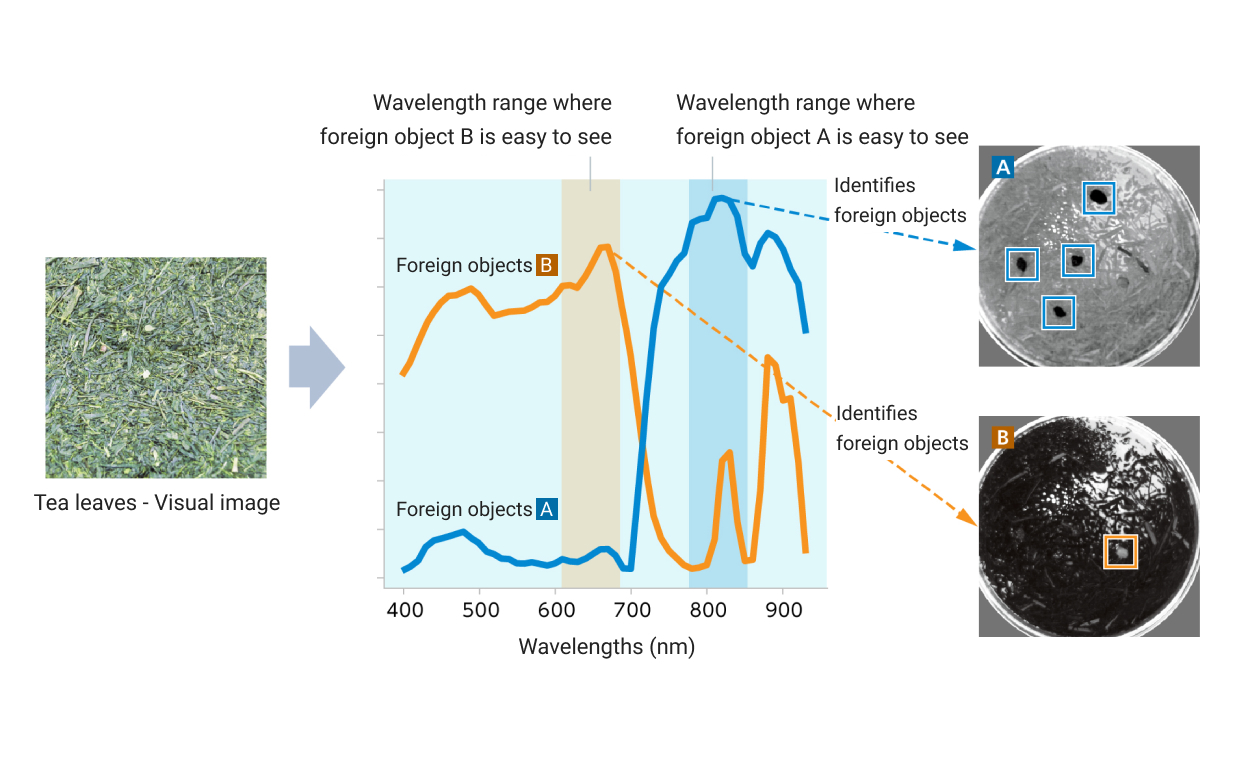

When inspecting for foreign substances during the food manufacturing process, detection accuracy is important. Food contains a variety of substances, so it is necessary to identify them based on their Spectral characteristics and detect foreign substances by combining this information with shape data obtained from images.

Technology Application Examples

Foreign Substance Inspection Equipment for the Food Industry

Amid growing awareness of food safety and security, the food manufacturing process requires measures to prevent the contamination of foreign substances and impurities. While metal detector machines and X-ray inspection machines are effective in detecting metal and plastic pieces, detection of objects like pieces of wood and hair mostly relies on the human eye. Nikon solved these issues using Spectroscopy and AI (Artificial Intelligence). We cover substances that conventional inspection machines struggle with and provide a foreign substance inspection system that is optimal for your products and manufacturing environment.

Click to enlarge

Technologies related to these examples

Related Technology

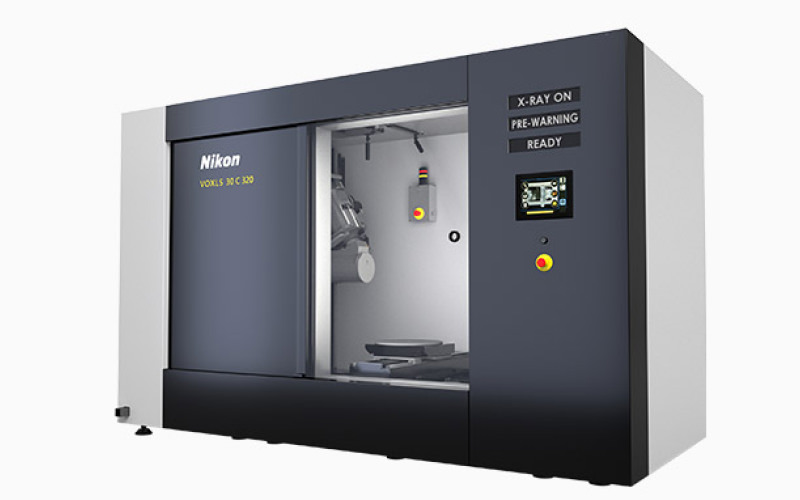

Internal Measurement

By irradiating light and capturing the optical response from inside an object, it is possible to obtain internal information non-destructively. In industrial applications, internal measurement methods like X-ray CT can be used for inspection of not only traditional components but also complex integrated structures created by 3D metal printers. In medical and research applications, it is possible to observe biological tissue as realistically as possible by acquiring microscopic images at each focal plane, like a confocal microscope.

Captured with episcopic GaAsP NDD for 1300 nm and CFI75 Apochromat 25XC W 1300 objective lens (NA 1.10, WD 2.0 mm), Excitation wavelength: 1040 nm

Photographed with the cooperation of: Drs. Ryosuke Kawakami, Terumasa Hibi and Tomomi Nemoto, Research Institute for Electronic Science, Hokkaido University

*Titles are as of the time of filming

Main Related Products

You can search for articles related to Nikon’s technology, research and development by tag.