Resin for Phase Fresnel Lenses

Technology Overview

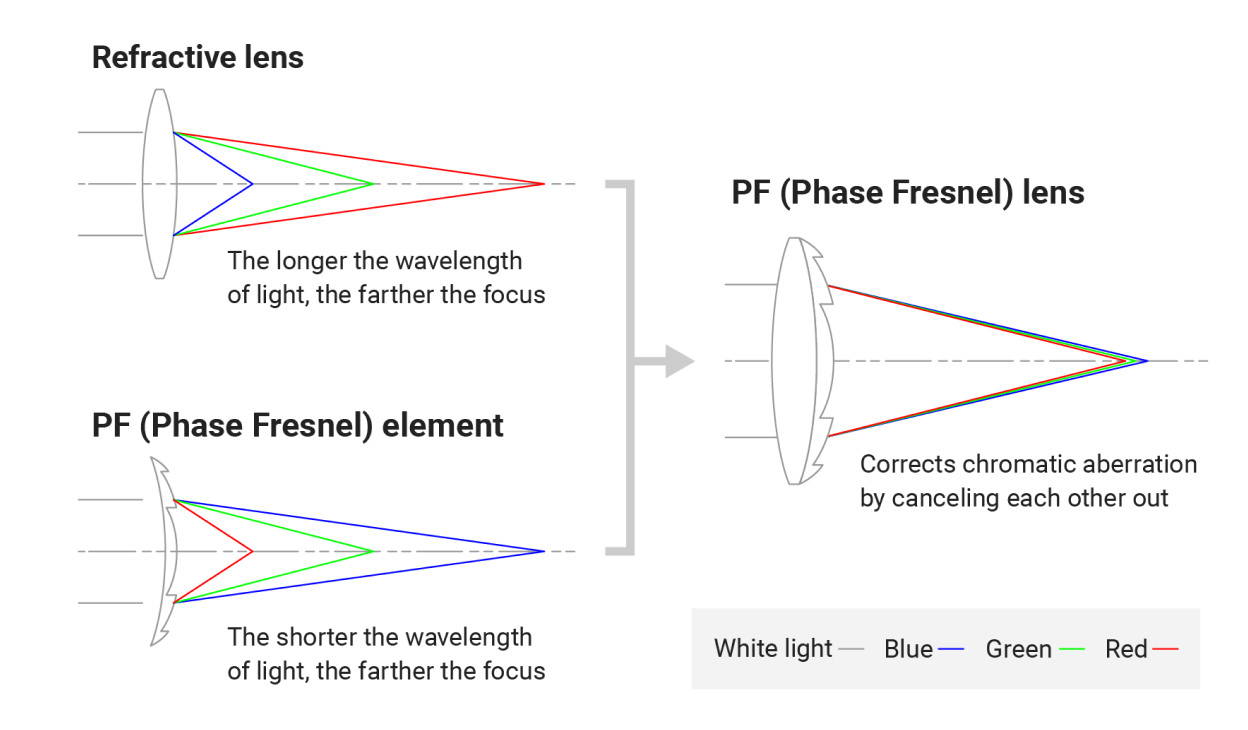

PF (Phase Fresnel) lens bends light using the phenomenon of diffraction. Unlike conventional refractive lenses, it forms images in the order of red, green, and blue from the side closest to the lens. PF lens allows for the cancellation of chromatic aberration by combining PF elements with traditional refractive lenses, achieving powerful correction of chromatic aberration. Additionally, PF lenses enable the optical system to be lightweight and compact. By using resin as a material for PF elements, it is possible to effectively control the wavelength dispersion of the refractive index, allowing for efficient correction of chromatic aberration. Due to the characteristics of the resin material, the transferability of the grating shape is also very good, enabling high productivity.

Click to enlarge

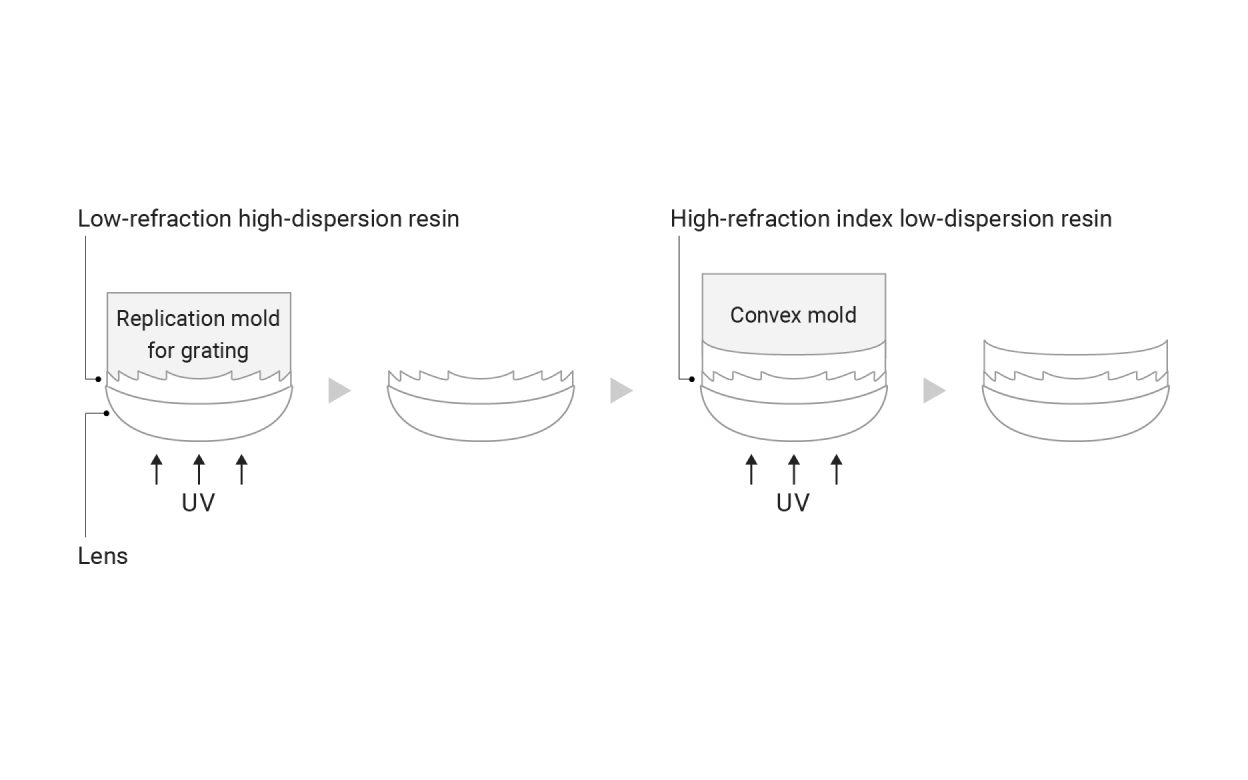

Phase Fresnel lenses require a diffraction grating to be engraved on them. For resin lenses, this is created by transferring the diffraction grating shape from a mold. It is essential to have adhesion that accurately transfers the mold shape and releasability that allows separation from the mold while maintaining the fine diffraction grating structure. Therefore, it is necessary to develop a resin composition and manufacturing technology that satisfies factors such as interface properties and viscosity, while ensuring the required optical properties.

Click to enlarge

Phase Fresnel lenses used in interchangeable camera lenses and other optical devices require optical performance across a wide wavelength range, reduced flare from diffraction gratings, ease of manufacturing, and robustness. To meet these requirements, Nikon employs a close-contact multi-layer type that bonds resin materials with high and low refractive indices and develops suitable resin compositions and manufacturing processes. Since resin has poorer weather resistance compared to glass, the stability of the dual-layer resin is also necessary to maintain optical performance.

Technology Application Examples

Telephoto Lenes

In order to shorten the total length of a telephoto lens, it is necessary to reduce the telephoto ratio (total length/focal length). If the telephoto ratio is reduced using only refractive lenses, the chromatic aberration that occurs in the convex group at the front of the lens will be magnified by the concave group at the rear, limiting how much the overall length can be shortened. A Phase Fresnel lens effectively counteracts chromatic aberration caused in conventional camera lenses, achieving excellent correction even with a shortened overall length. Shortening the overall length of the optical system makes it possible to shorten the lens barrel, resulting in lighter and more compact telephoto lenses.

Technologies related to these examples

Related Technology

Optical Resin

Resin is lightweight and can be mass-produced at a low cost, even though it may be inferior to glass in terms of durability and light transmittance. As a type of polymer compound, its composition, additives, and polymerization methods can be adjusted to create materials that meet various specifications.

Nikon effectively applies optical resins to consumer products such as cameras, which are lightweight and require mass production.

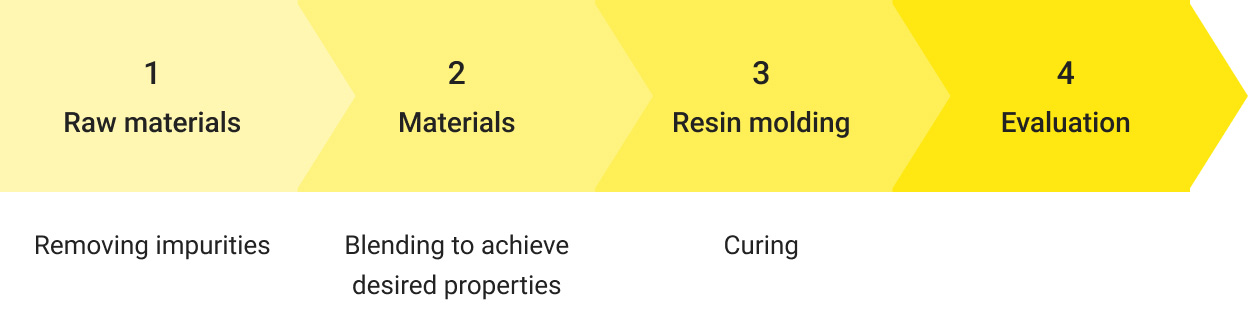

As with glass, it is important to develop a composition that satisfies the optical properties required by optical design and is weather resistant, as well as a manufacturing process that allows for efficient mass production. Since resin has a higher coefficient of thermal expansion than glass, it is necessary to take measures to minimize the effect on optical properties. If no resin with the required optical properties exists, it is necessary to synthesize it using raw materials. Therefore, we conduct research into chemical synthesis, develop molding processes, and evaluate the molded lenses.

Click to enlarge

Main Related Products

You can search for articles related to Nikon’s technology, research and development by tag.