Extra-low Dispersion Glass

Technology Overview

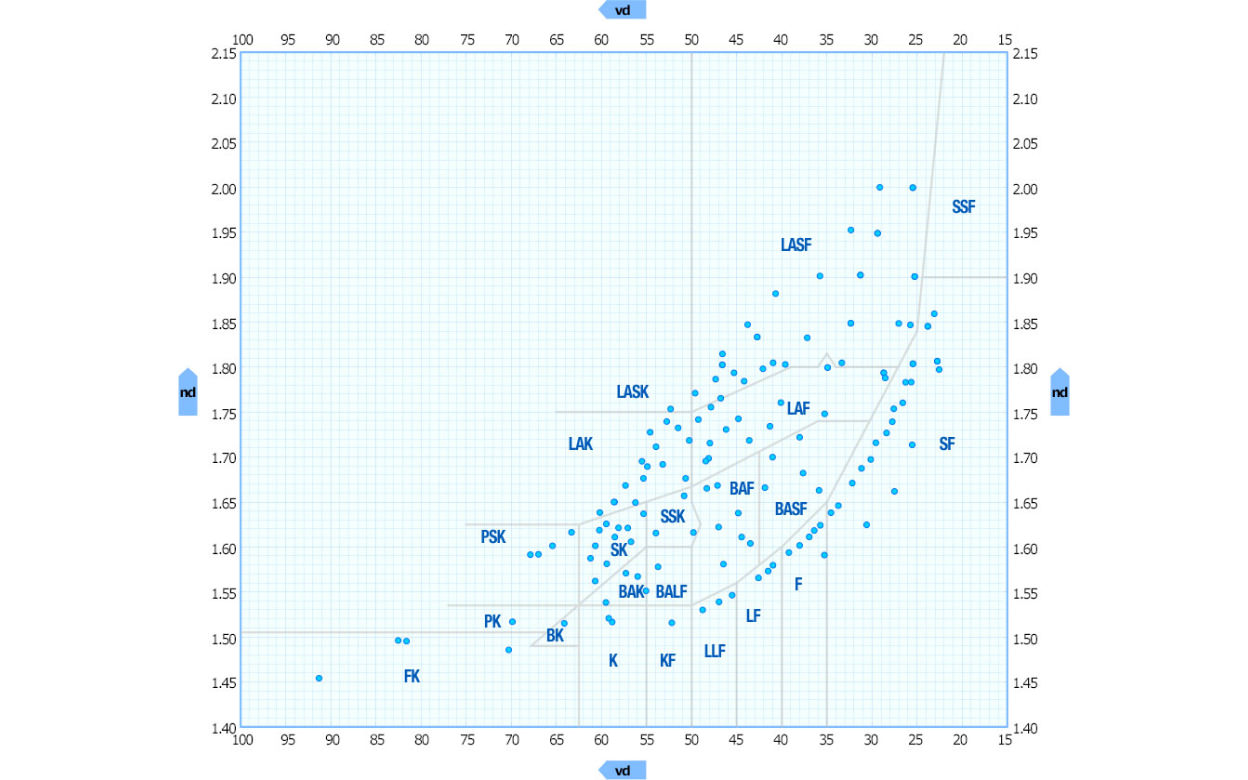

Also called anomalous dispersion glass, its refractive index wavelength dependency differs from that of general optical glass in certain wavelength ranges. This allows for effective chromatic aberration correction when combined with general optical glass. It is easier to manufacture and process than fluorite, which has similar optical properties, and can be used in many optical products.

Compared to general optical glass, it has a lower viscosity when melted, so it tends to crystallize, and some components tend to volatilize, making it more likely to become heterogeneous. In order to vitrify with the desired composition, it is necessary to manufacture it while appropriately controlling the temperature and anticipating volatilization.

Click to enlarge

Because it is powerfully effective at correcting chromatic aberration, it is used in a wide range of products such as cameras, binoculars, and telescopes. Furthermore, lithography systems that uses mercury lamps as a light source also requires chromatic aberration correction and thus requires high-purity glass.

Technology Application Examples

Binoculars

Visible light is composed of light of various wavelengths, and the ideal objective lens should focus all wavelengths onto a single point. However, since light is bent in the same way as a prism, a single lens generally has a different focal length for each wavelength. As a result, light of each wavelength does not focus on the same location, causing chromatic aberration.

Achromatic objective lenses using general optical glass materials can match the focal length for two wavelengths. For example, by matching the focal lengths of red and blue wavelengths, which are the extreme wavelengths of visible light, chromatic aberration can be suppressed to some extent. However, if one looks closely, other wavelengths, such as green wavelengths, have different focal lengths, resulting in residual chromatic aberration. This residual chromatic aberration is called the secondary spectrum.

The secondary spectrum cannot be corrected with general optical glass combinations and requires optical materials such as ED (Extra-low Dispersion) glass with special dispersion properties. When combined with other glasses, ED glass can reduce the value of the secondary spectrum to a very small value, making it possible to dramatically reduce chromatic aberration compared to conventional achromatic objective lenses.

Technologies related to these examples

Related Technology

Optical Glass

Optical glass is an essential material for manipulating light in optical systems, and its quality is crucial. Impurities must be removed, and it needs to have uniform optical and mechanical properties.

By manufacturing each of the many glass compositions with the optimal process, we can obtain glass with the specifications required by optical design, achieving not only excellent optical performance but also smaller size, lighter weight, and lower cost.

Nikon manufactures a variety of optical equipment, which requires glass with diverse optical properties. Projection lenses for semiconductor lithography systems and other devices require materials that transmit wavelengths in the ultraviolet region and are resistant to laser light, while camera lenses need materials with low specific gravity and impact resistance in the visible light region. In order to correct aberrations by combining materials with different optical properties, it is necessary to develop composition and manufacturing processes.

Main Related Products

You can search for articles related to Nikon’s technology, research and development by tag.