Analyzing NIKKOR lens characteristics

Nikon constantly works as an optical manufacturer to advance the development of interchangeable lenses for cameras, while also focusing on the research

and development of an evaluation system for optical performance.

Using OPTIA, which can measure lens characteristics in combination with an image simulator that generates a simulated image based on data,

Nikon realizes lens development by controlling these characteristics.

Natural three-dimensional reproduction depends on bokeh

A camera captures an irreplaceable moment that can never be experienced again, according to the photographer's feelings and intentions. For that to happen, the lens needs to provide not just resolution, but also various qualities such as bokeh, reproduction of textures and sense of depth — what we call lens characteristics.

Recently, Nikon has been pursuing natural three-dimensional expression. Putting an emphasis on a perfectly smooth transition of bokeh from the focused area, Nikon is developing lenses that bring a sense of three-dimensionality to the two-dimensional world of photography.

These bokeh are related to lens aberrations. Aberrations are distortions between the ideal optical image and the actual image, and they come in various forms: spherical aberration, coma, astigmatism, field curvature, chromatic aberration, etc. In theory, an ideal lens would produce no aberrations, but in reality, they remain for various reasons. How to compensate for each aberration, and balance them, depending on the characteristics of the lens, are the "values" of a lens in optical design. In relation to this, bokeh cannot be obtained from post-processing of an image once it has become two-dimensional data. It is similar to when analog information is digitized, in that the original analog information can never be reproduced. It is expression that only a lens with certain characteristics can create.

It used to be difficult to analyze the characteristics of a lens, and such nuances were conveyed orally from one designer to another. This made it extremely difficult to reproduce the characteristics of an existing lens.

That changed when Nikon developed lens evaluation methods that can measure various characteristics, including aberrations. Since these were introduced in 2013, it has become possible to develop lenses that fulfill the designers' intentions over a much shorter period of time.

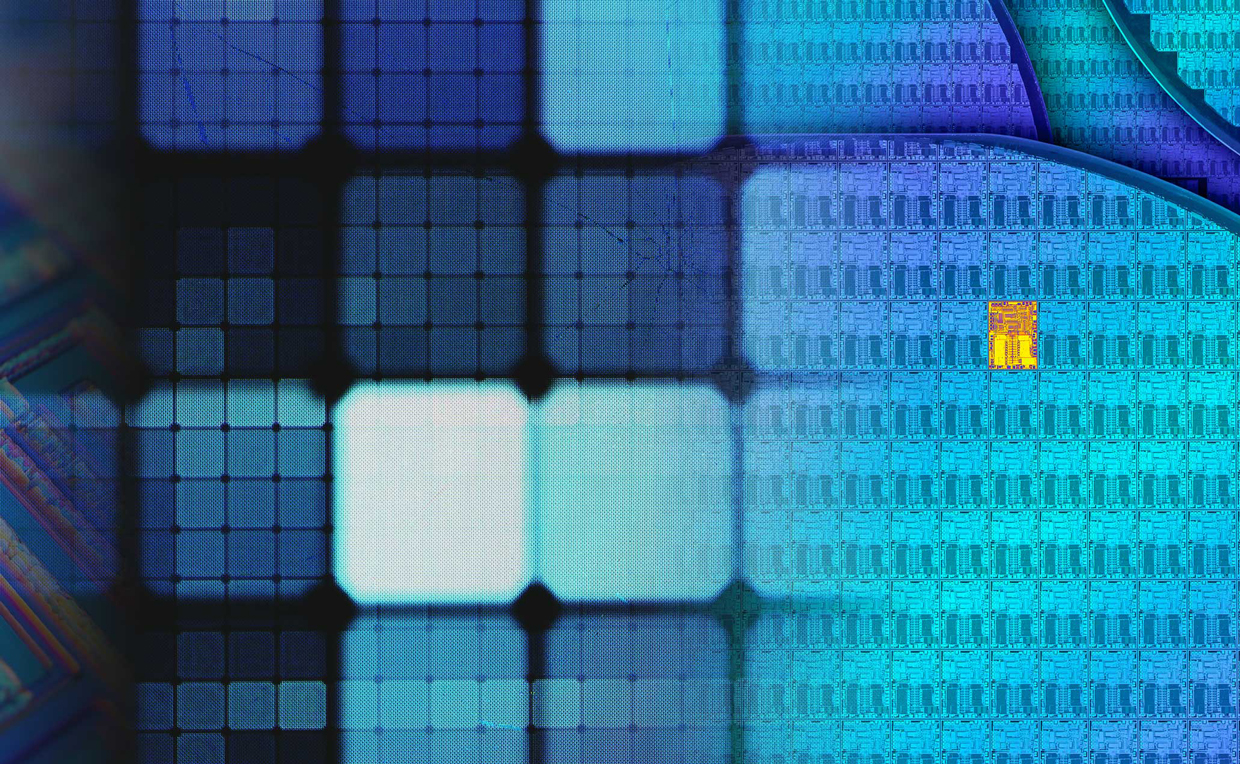

Measuring nuances by analyzing wavefront aberration

One of these methods is the Optical Performance and Total Image Analyzer (OPTIA), a device for measuring aberrations. OPTIA was created by repurposing the "wavefront aberration*" measurement method, originally used for lens evaluation of semiconductor lithography systems, and applying it to camera lenses.

Wavefront aberration information includes data that influences bokeh. In other words, by measuring and then analyzing wavefront aberration, the characteristics of each lens can be obtained.

Being able to measure lens performance from various angles enables more thorough quality control. It also makes it possible to understand the characteristics of legendary older lenses, which can be researched and utilized in future lens development.

- *Wavefront aberration is the deviation between the spherical wave (a light wave converging in a spherical shape toward the image) after passing through a theoretically ideal lens, and the wavefront after passing through the lens. In an ideal lens, light emitted from a point converges to a point through the lens, so the wavefront after passing through the lens is a spherical wave. In an actual lens, the wavefront does not always converge on the point, and the wavefront slightly deviates from the spherical surface. This deviation from a spherical wave is known as wavefront aberration.

Another evaluation method is the image simulator. This software uses lens information measured and analyzed by design data and OPTIA to generate a simulated image taken with the lens.

The characteristics of a lens can be measured with OPTIA. In addition, since human sensibility determines whether an image is actually good or bad, it requires human eyes to actually evaluate what kind of image will be created with those characteristics. In the past, a prototype lens was physically manufactured, and used repeatedly to take images for evaluation. However, it is now possible to confirm bokeh and reproduction of textures, etc. by looking at the simulated image generated by the image simulator.

OPTIA provides data for designers to use as a guide, and the image simulator creates simulations based on the design. These techniques have led to major innovations not only in the level of quality control for lens manufacturing, but also in the lens development process. Such innovations support Nikon's aim to constantly raise the bar for lens development.

Examples of lenses created with OPTIA

The following lenses were developed using OPTIA and the image simulator, and are shown together with images representing their characteristics.

NIKKOR Z 50mm f/1.8 S

A new-generation, fast, standard prime lens employing the Nikon Z mount. It realizes high resolution that faithfully reproduces the texture of subjects as well as producing soft and beautiful bokeh even at short distances.

AF-S NIKKOR 35mm f/1.8G ED

A compact and lightweight, fast, wide-angle lens that provides high resolution and sharp rendering. It enables image expression utilizing the elaborate bokeh characteristics that can be achieved with a fast lens.

AF-S NIKKOR 58mm f/1.4G

A fast, standard prime lens that realizes both superior point-image reproduction that renders point light sources as sharp points and beautiful bokeh, enabling distinctive space expression.

AF-S NIKKOR 105mm f/1.4E ED

A fast, medium-telephoto prime lens that provides beautiful bokeh with gradual alteration of the degree of bokeh from the focal plane, delivering a sense of depth naturally.

In-house knowledge essential for development

Production Technology Division

Yasushi Fukutomi

I am in charge of mechanical design, and have been the OPTIA development leader since the project started. Wavefront aberration isn't something you can measure with a single reading. Multiple readings need to be taken, for things such as subject location, shooting distance and light wavelength. The measurement conditions are different from lens to lens, and there are enormous variations. This means OPTIA has many moving parts and light sources that need to be switched, and it was difficult to make the components a practical size. It was particularly challenging to eliminate the positional differences between the landscape and portrait orientations of a lens. Considering the mechanical structure, the device would become unrealistically large. By taking advantage of the wisdom of optical designers, we were able to develop a device that measures the position differences simultaneously, then corrects them later.

Optical Engineering Division

Kei Ito

I was responsible for the sensor algorithm for wavefront measurement, as well as analyzing optical error factors, etc. I joined the project during my second year at the company, and am still involved now. Photography preferences are becoming ever more diverse; for instance, as resolution increases, images with certain characteristics are favored. In the future, some people may feel that it is more interesting to preserve certain kinds of aberrations in a lens. To meet such needs, I believe that offering a varied lineup of lenses — such as lenses that eliminate aberrations as much as possible, and lenses that retain particular characteristics — will make photography more enjoyable for everyone. While it may not seem realistic from a cost perspective for now, perhaps it wouldn't be so implausible to provide a fully customized lens that meets a user's precise preferences at some point in the future.

Optical Engineering Division

Yukimasa Uchiyama

I was in charge of organizing the project as an image simulator development leader. The image generated by the simulator is extremely high definition, so it can be evaluated in almost the same way as an actual image. This makes it easier than ever to reflect designers' exact intentions in the lens.

I believe that OPTIA and the image simulator have greatly expanded the area that designers can work in. Since the simulation uses such a large amount of data, it was difficult to decide the appropriate conditions. Luckily, there is a lot of cooperation within the company, so we can always consult freely with designers and draw on their diverse knowledge. Taking advantage of this environment, I was able to develop systems that provided just the right solution, by consulting with various people who possessed the knowhow I needed to achieve my goal.

- *Job titles and responsibilities are as of the time of the interviews.

Originally published: September 30, 2019.