Manufacturing

Committed to quality from product planning to production

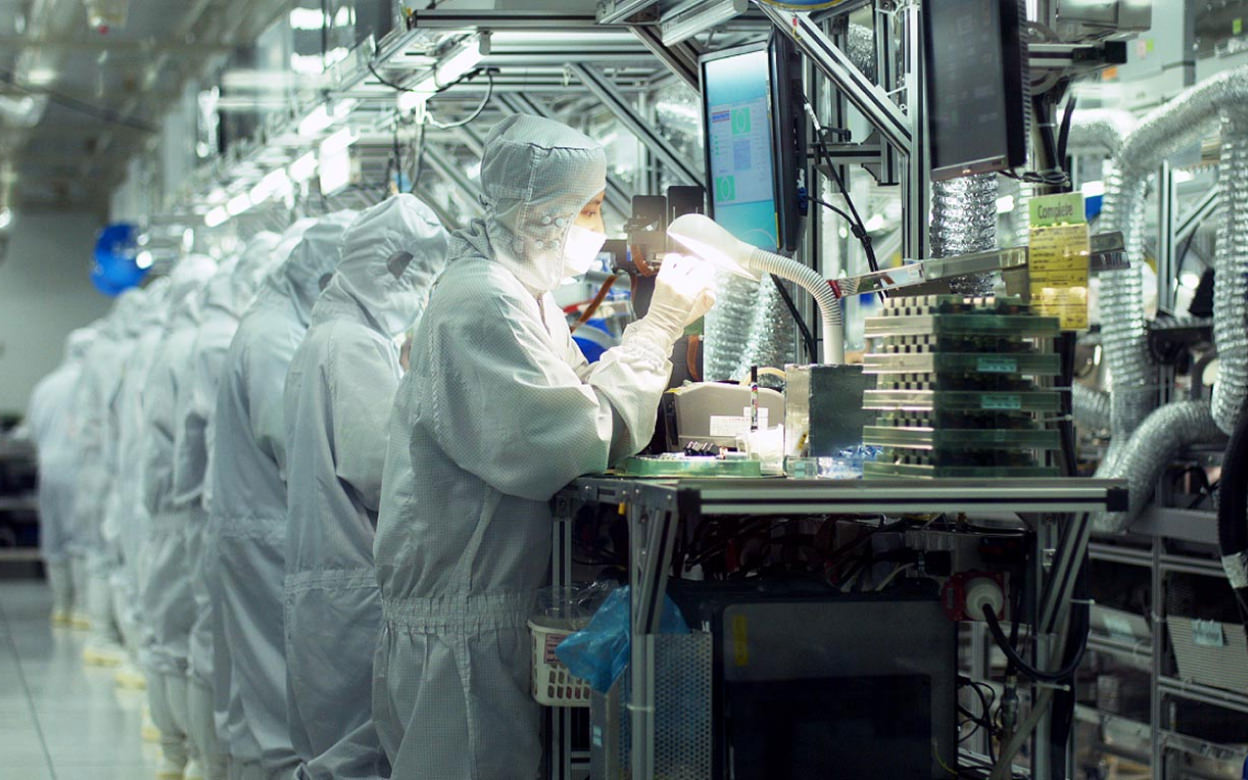

Nikon handles B2C products for individual customers and B2B products for corporate customers. B2C products include cameras, glasses, and binoculars, while B2B products include high-precision industrial robots and manufacturing equipment, their components, and microscopes used in research institutes and hospitals. We respond to the diverse quality, price, and delivery time requirements for each product.

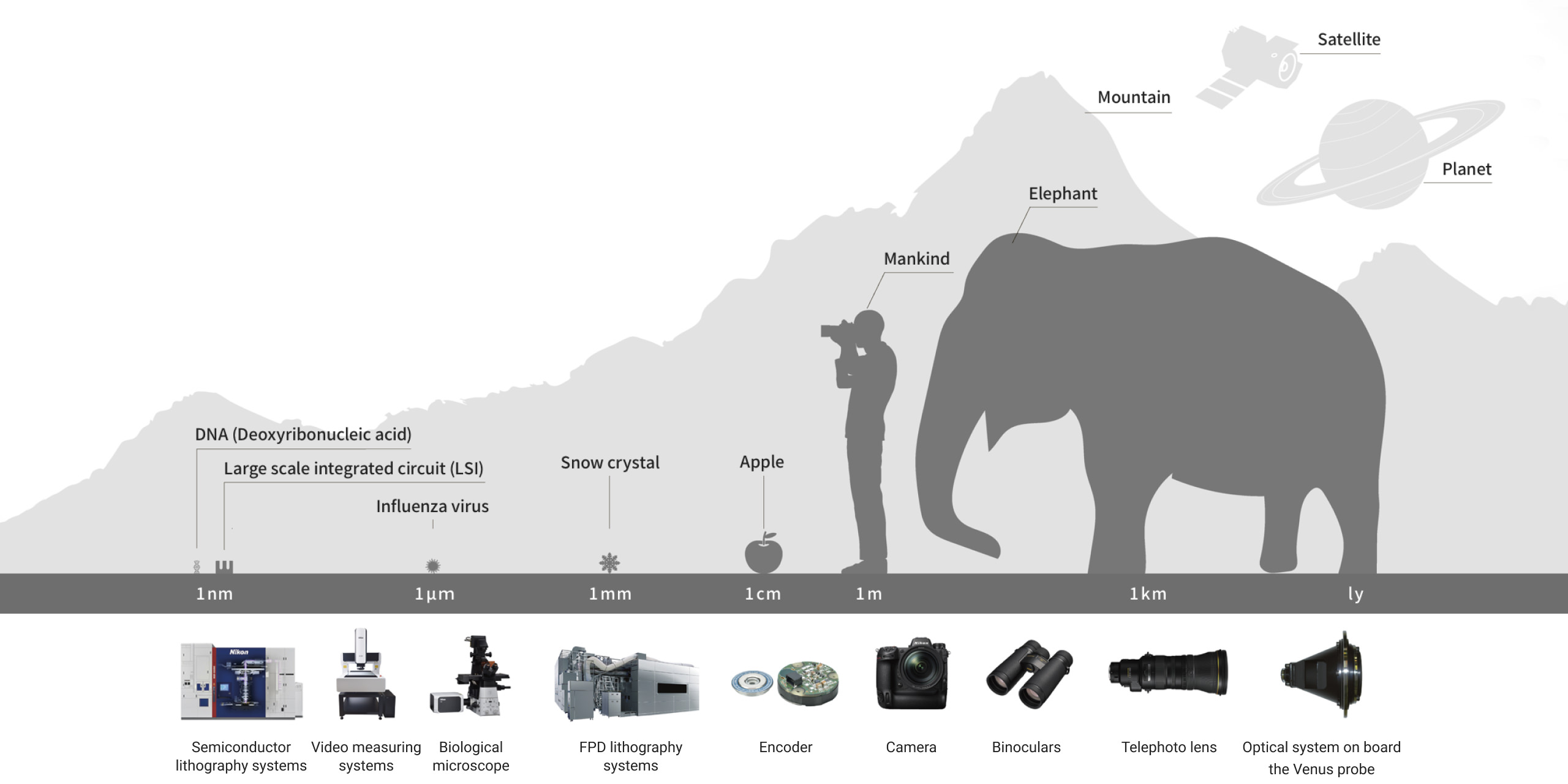

For example, our products range from semiconductor lithography systems with world-class precision measured in nanometers (1 nm = 1 millionth of a millimeter) to microscopes, industrial robots, cameras, and optical instruments for artificial satellites that view Earth from space, approximately 40,000 km in circumference. We meet all required precision levels.

Click to enlarge

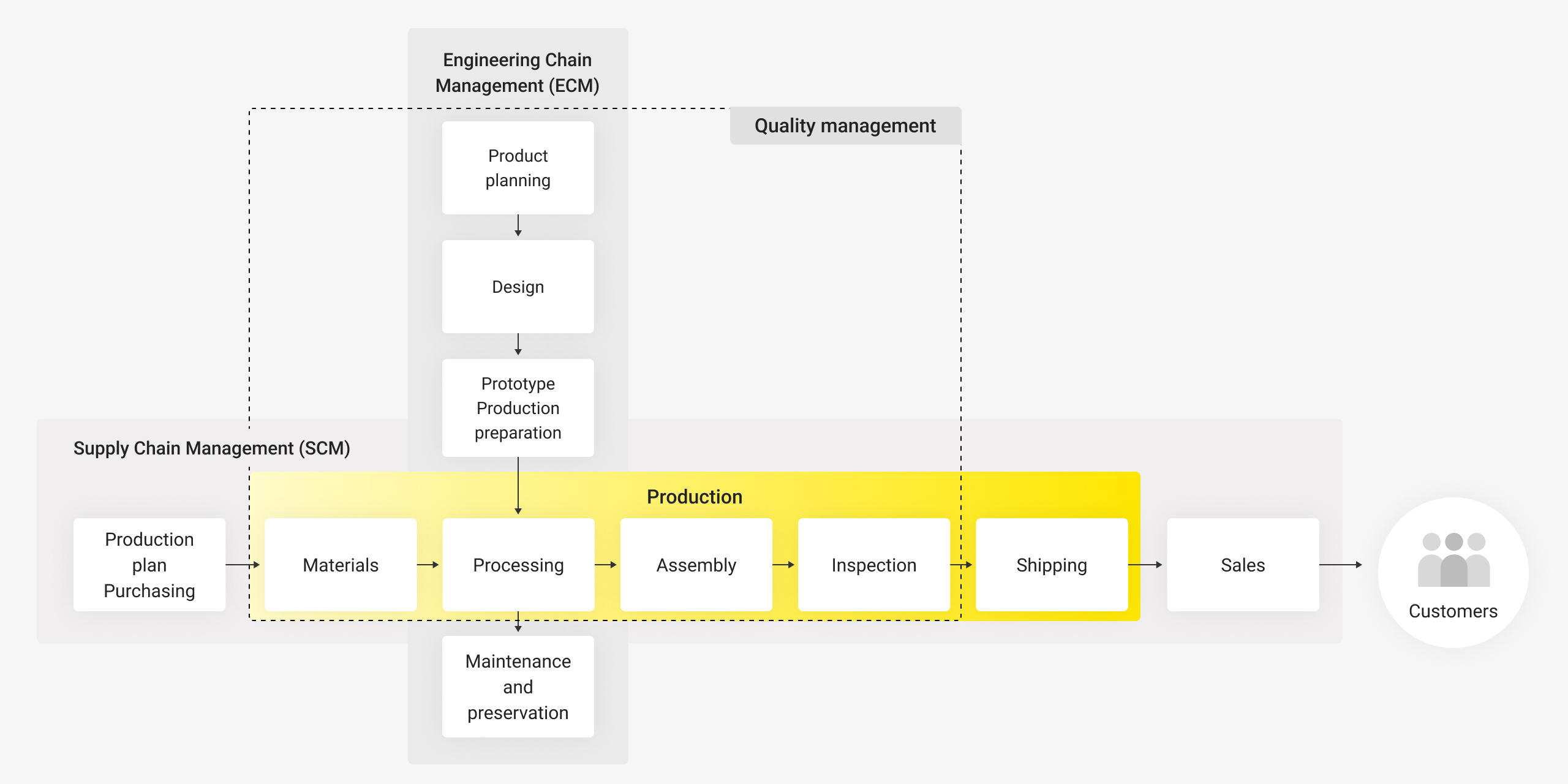

Nikon products sold overseas must maintain "Nikon quality" regardless of where they are made. To accurately meet customer needs in quality, price, and delivery time, we have implemented an optimized Engineering Chain Management (ECM) and Supply Chain Management (SCM) system across the entire Nikon Group, including our group companies, to ensure product quality. This supports Nikon's manufacturing.

Manufacturing involves planning, designing, prototyping, and producing products while applying elemental technologies obtained through parallel or advanced development.

Click to enlarge

Manufacturing Activities

Planning, Design, Prototyping

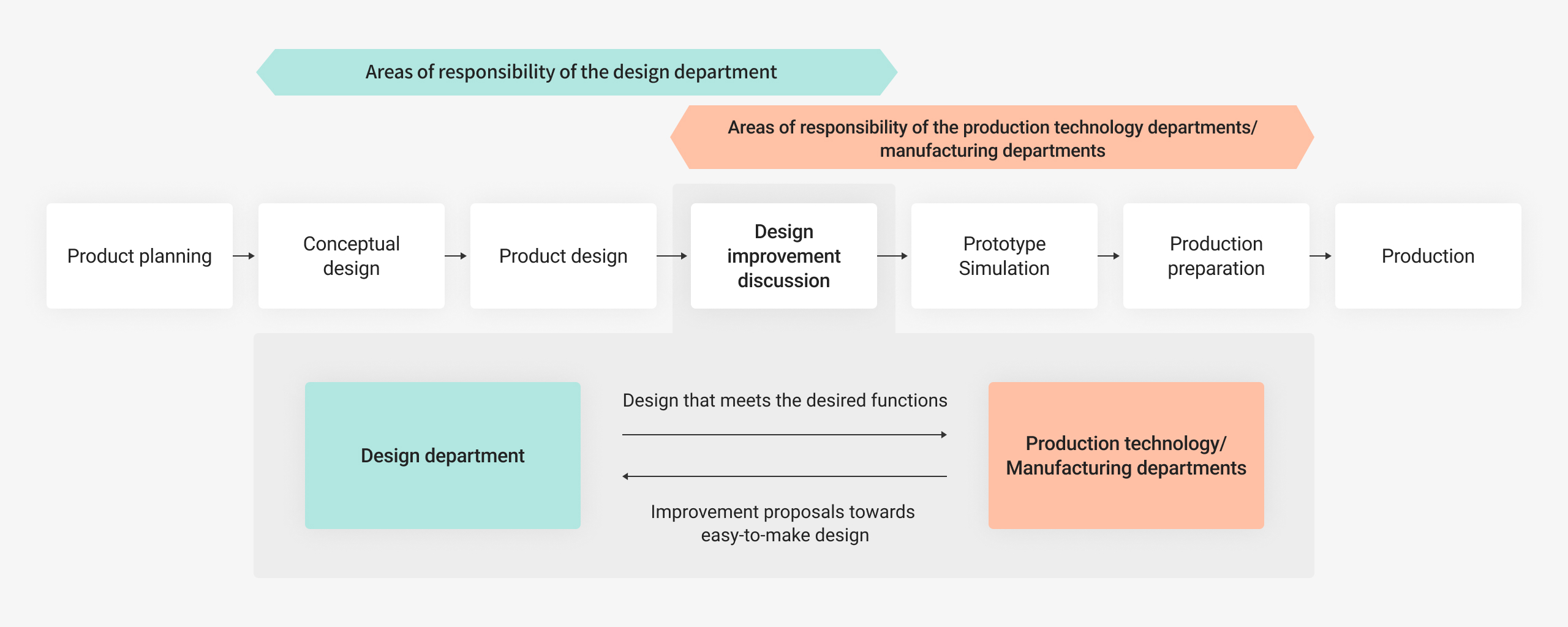

In the early stages of the engineering chain, we plan products that can deliver the services our customers want and set specifications during the conceptual design phase. To meet these specifications, we design products, create detailed drawings, and verify that the prototypes based on those drawings meet the expected specifications. We are also on front loading, considering prototyping and manufacturing in advance. By aggressively utilizing 3D models and simulations, we prototype and development costs and time.

During the design stage, we hold discussions with the manufacturing site and the production technology department to gather feedback from a manufacturing and production design perspective.

We incorporate this feedback into the design to improve the quality of drawings, enabling manufacturing sites to produce products more easily and with low costs.

Click to enlarge

Production

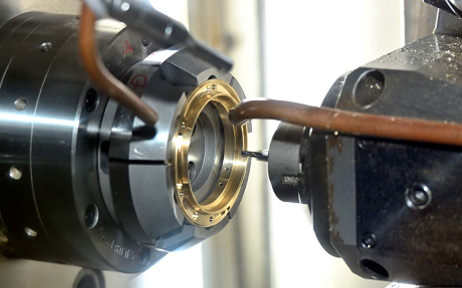

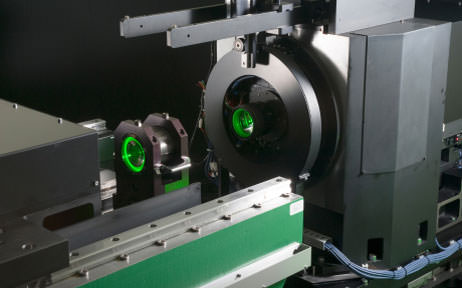

Nikon, including its group companies, covers the entire supply chain from materials to manufacturing before shipping. Especially for optical components, we handle them in-house. We manufacture special glass materials, such as optical glass, synthetic quartz glass, and fluorite, within the Nikon Group. These materials transmit light in a wider wavelength range than ordinary glass. The lenses used in Nikon products manipulate light of various wavelengths and intensities for a variety of purposes, allowing precise control.

For products assembled within the Nikon Group, we process these glass materials and mechanical parts.

Parts are assembled with high precision and inspected according to strict standards. All processes, from shipping to sales, are carried out within the group. To meet the world's highest standards of precision, production and inspection equipment for processing and assembly are developed and manufactured in-house as needed.

By covering a wide range of products within the Nikon Group, we provide products with unified quality standards, ensuring stable quality for society.

Quality management

The Nikon Group has established a quality management policy known as the "Basic Quality Policy" and is implementing it. We have formulated and are implementing the "Quality Management Directive" (QMD).

The QMD outlines the basic requirements that must be met throughout the entire operations flow and deliverables, covering ECM and SCM processes.

The instructions set at each stage of Nikon Group's operations are based on this QMD.

The Nikon Group operates this quality management system, continuously evaluating and responding to changes in external regulations and other factors, thereby ensuring that we meet the expectations and requests of our customers. We provide high-quality products at the right time and at the right price. We are able to manufacture products with "Made by Nikon" quality at all of our production sites around the world.