Product Manufacturing and Social Contributions through Sharing Our Vision with Procurement Partners

highlight

To create better products and also make society a better place, Nikon shares its approach to CSR with its procurement partners who supply the raw materials and parts, and works side-by-side with these companies to implement our approach.

Strong Cooperation with Procurement Partners to Form the Foundation of Nikon’s Monodzukuri

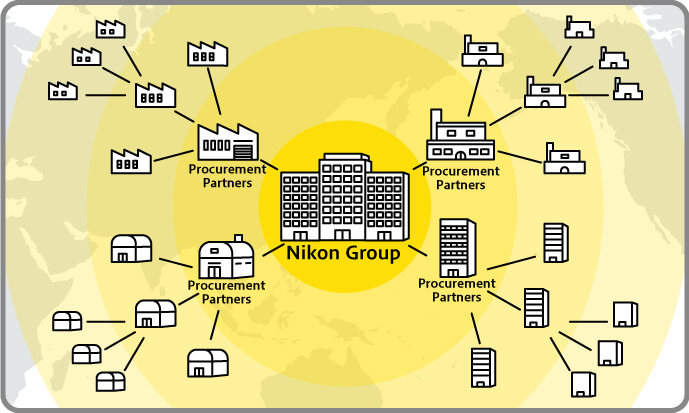

Nikon manufactures and assembles nearly all products within the Nikon Group. For this reason, Nikon’s procurement of the raw materials and parts is underpinned by a variety of suppliers inside and outside of Japan, representing various industries, including metals, resins, and optical and electronic components.

At the same time, society has developed a greater interest regarding monodzukuri in terms of such issues as human rights issues at the mining sites of minerals used as metal materials, the labor environment at factories, the management of chemical substances, and climate change countermeasures. These issues require efforts that go beyond the Nikon Group to encompass suppliers and the entire supply chain.

During the process of supplying high-quality products and solutions that benefit society, it is vital that Nikon cooperate with suppliers to fulfill CSR and to address these social issues. Based on this recognition, we refer to our suppliers of raw materials and parts as procurement partners, and we strive to deepen mutual understanding and build trust with these partners. Moreover, we ask procurement partners to cooperate so that we can work on CSR together.

Nikon’s supply chain around the world

Sharing Our Vision through Step-by-step Initiatives

First, we established the Nikon Procurement Partner’s CSR Guidelines (“the Guidelines”) and held briefing sessions about them. To obtain the cooperation of procurement partners, we believe it is important to share our commitment. This is why we first documented our approach to CSR and requests for procurement partners using the Guidelines, and then initiated activities to explain them so as to gain their complete understanding.

These activities proved to be a series of trial and error. In 2007, at the time of the first briefing session, there were few people in Japan familiar with the word CSR, so we had to start by explaining CSR at a basic level.

At the same time as holding these briefing sessions, Nikon also conducted an assessment of its procurement partners. This assessment initially focused on the penetration of the Guidelines. Afterwards, through repeated dialogue with each procurement partner, we made progress in stages to check the partners’ understanding of the Guidelines and then identify the actual status of implementation.

In 2015, we took these activities to the next level. We replaced the Guidelines with the newly established Nikon CSR Procurement Standards (“the Procurement Standards”) to create a system for encouraging improvement.

Procurement Standards as a Common Language

The Procurement Standards serve as a common language to ensure Nikon moves in the same direction with its procurement partners around the world.

Nikon’s main manufacturing sites are located in Japan, China and Thailand, and many of our procurement partners also operate in these three countries. Business practices differ among these countries, and depending on the region, issues and people’s acceptance of CSR may differ. Some have even questioned why companies have to fulfill social responsibilities. While expanding these activities outside of Japan, we found that the Guidelines had been prepared mainly with Japanese companies in mind, which made it feel like the level demanded by Nikon was vague and difficult to convey. There was also a need to address new social issues that had emerged since the Guidelines were first established. The Procurement Standards were compiled to cover these issues.

Based on the Procurement Standards, Nikon conducts CSR assessments using a self-check format and performs CSR audits where auditors visit procurement partners to confirm their implementation directly. These results are analyzed to support the improvement activities of procurement partners. Dialogue plays an important role in encouraging procurement partners to understand the results and ensuring that they take actions necessary for improvement.

Today, more than 10 years since Nikon first began this initiative, there are still procurement partners who are skeptical about the need for compliance with the Procurement Standards. Toward them, we convey that our standards are in place to protect their company and employees. For example, the Procurement Standards include detailed instructions such as to display emergency evacuation routes, and we highlight the dangers of fires. In this way, we continue to raise awareness creatively, and motivate them to take ownership of their actions.

Nikon expects more people to understand these Procurement Standards so that they function as a common language and procurement partners steadily move forward with activities. This dialogue must reach not only those who take part in the briefing sessions, but also their colleagues and people from other departments. As such, Nikon is expanding learning opportunities at the individual level using online systems.

History of Main Activities

- 2007: Established the Nikon Procurement Partner’s CSR Guidelines.

- 2008: Held briefing sessions on the Guidelines for procurement partners in Japan, and conducted assessments using a CSR questionnaire.

- 2009: Presented the Guidelines and conducted assessments for procurement partners outside Japan that do business directly with Nikon Group companies in Japan.

- 2010: Began holding briefing sessions on the Guidelines and conducting assessments for Group companies outside Japan and their procurement partners.

- 2015: Replaced the Guidelines with the Nikon CSR Procurement Standards. Initiated CSR assessments and CSR audits, along with requests for improvement and provision of support.

- 2019: Began learning assistance for procurement partners using educational tools. Established the criteria on compliance rate with the Procurement Standards and began including it in terms and conditions of doing business.

Voice of a Procurement Partner

Through Nikon’s CSR assessment and CSR audit, we were able to take notice of our weaknesses in terms of occupational health and safety, and compliance. Currently, we are working as a company to improve and remedy these issues, and we are able to sustain these activities thanks to periodic support by Nikon. Through improvement activities, we have been able to increase awareness toward fulfilling CSR and implement specific actions. Going forward, we will examine what we can do from a global perspective and deepen our partnership with Nikon, aimed at offering even better products and making society a better place.

Shinwa Controls Co., Ltd.

Working Together with Procurement Partners around the World

To create procurement standards that are accepted and comprehended by all, we worked diligently to examine the latest worldwide trends in CSR, to study several global standards, to incorporate the views of specialist departments in-house to ensure consistency with the Nikon Code of Conduct, and to make sure there were no gaps with existing guidelines. Precisely because of these comprehensive preparations, the Procurement Standards function today in our global assessment and audit activities. Looking ahead, we hope to work not only with procurement partners, but also with their suppliers directly; in other words, the companies supplying materials to our procurement partners. Nikon’s products involve a large number of companies, from the manufacture of raw materials to sales. As a global company, we feel it is our responsibility to provide comprehensive and ongoing support for improvements to empower these companies to take notice of their own issues, such as prolonged working hours or continuous work, as a way to find solutions to social issues.

Procurement Department Production Technology Division

In one country, a large number of employees are migrant workers from rural areas, and we were told that they didn’t want stricter controls of working hours because they didn’t want to lose income. As such, during the country’s briefing session, we presented data on the heightened risk of death from overwork when working prolonged hours without resting. We also spoke about how a company with a healthy workplace is able to maintain high quality and stable production. In this manner, I feel like we have been able to gradually increase understanding of Nikon’s approach and Procurement Standards by selecting the points to emphasize and examples to present during briefing sessions according to the country and region. We have seen an increasing number of positive responses from managers at procurement partners that underwent audits and received support for improvements, saying “We became a better company after making continual improvements following the Procurement Standards.” This indicates we are really getting through to our procurement partners.

Procurement Department Production Technology Division

- *Affiliations and job descriptions are current as of the time of the interview.

OutlookIncreasing All Procurement Partners’ Compliance with the Procurement Standards

Our current target is to increase the rate of compliance with the Procurement Standards among all procurement partners so that it exceeds the management standard. Toward this end, Nikon will take steps to better understand the current status through continued CSR assessments and CSR audits, and provide steady support for improvements to procurement partners with a low rate of compliance.

Next, we plan to expand this initiative to the suppliers of our procurement partners.

The Procurement Standards follow the Responsible Business Alliance* Code of Conduct, an international standard on CSR in the supply chain, and contain common provisions on labor, health and safety, and the environment, among others, that must be followed by all procurement partners everywhere in the world.

Nikon will continue to lead its procurement partners so that they comprehend the Procurement Standards and work together in our CSR initiatives. This will enable us to build a high-quality supply chain that shapes a better society and creates products that make everyone’s lives even more prosperous.

* An international coalition dedicated to supply chain responsibility (labor, health and safety, environment and ethics). Responsible Business Alliance’s member companies began with European and North American companies in the electronics industry. Today, Asian companies have also joined, and the represented industries have expanded to automobiles, toys and retail, among others.

Related SDGs

SDGs: Sustainable Development Goals

In 2015, the international community adopted a set of targets for sustainable development, to be achieved by 2030. The 17 global goals address issues such as poverty, hunger, education and climate change.

Highlight

- The Power of Imaging: Bridging Space and Earth

- Exploring possibilities for imaging expression with the creators of tomorrow

- Riblet Processing — A Technological Innovation for Aircraft Leading Toward Achieving Carbon Neutrality

- Reusing semiconductor lithography systems to reduce waste

- Supporting children’s education in Laos

- Providing solutions for iPS cell-based drug discovery

- Reducing CO2 emissions from lens manufacturing process through technology

- Product Manufacturing and Social Contributions through Sharing Our Vision with Procurement Partners

- Fostering “Image Culture” through the Nikon Photo Contest A Conversation with those Inspired by Photography

- Worldwide employee training: ensuring Nikon remains a company that people trust

- Superior quality born from a collaborative production process