The profile projector: the unsung equipment supporting the precision of manufacturing

No.5 | 1939 | Checking the precision

The Nikon profile projector was launched in Japan in 1939, during turbulent times. As its name suggests, it performed a wide range of roles, such as inspecting precision components, investigating oil deposit distribution, and validating banknotes. This product was familiar only to those in the know that supported Japanese industry during the reconstruction period. The “pursuit of precision” which is Nikon’s essence had begun.

Contents supervisor: WIRED JAPAN, Japanese text: Shuto Mizutani, Photography: Junpei Kato, Editing: Shinya Yashiro

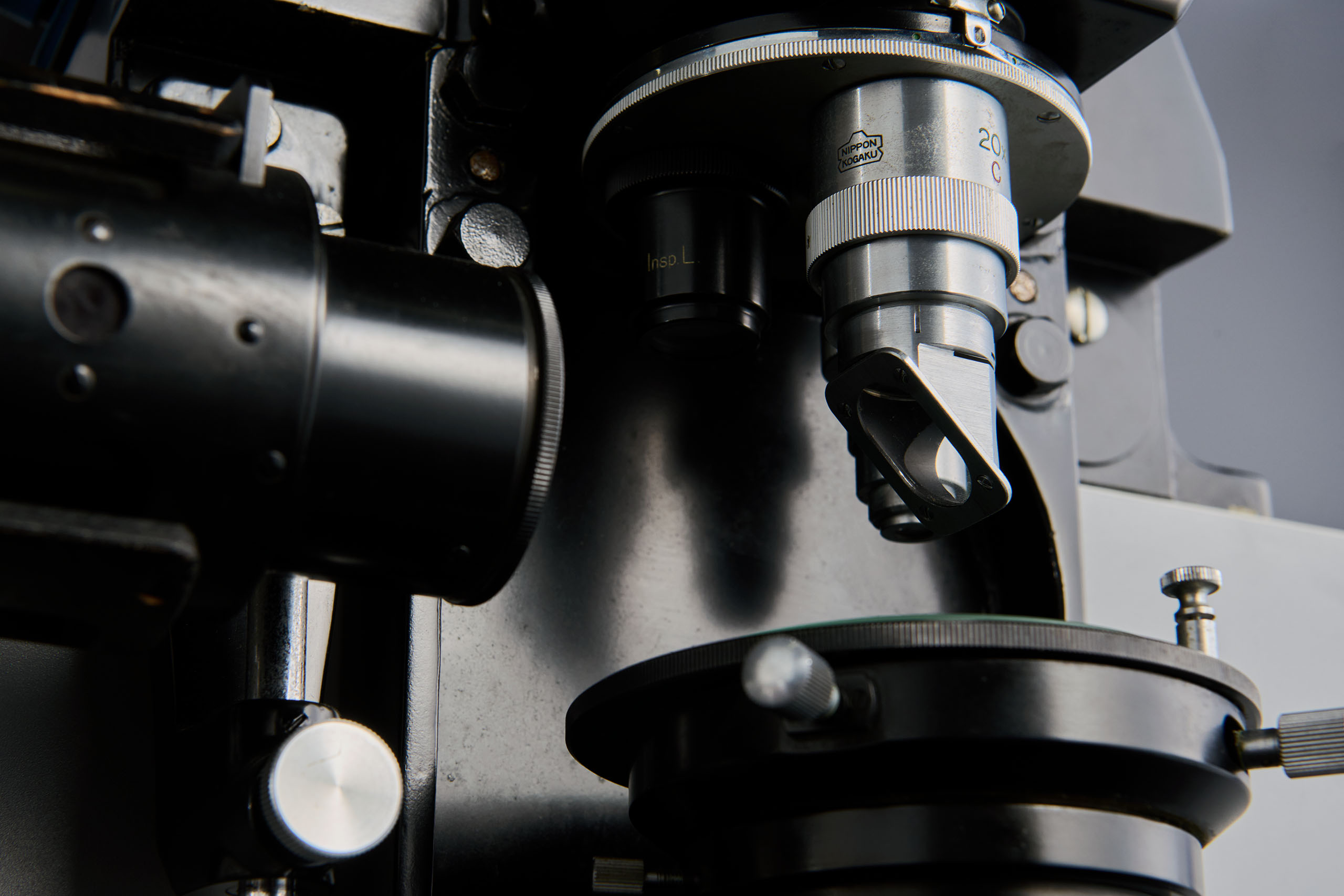

What Japan’s manufacturing industry had been looking for in the past was technological innovation for manufacturing. In 1939, Nippon Kogaku K.K. (now Nikon Corporation) created a prototype “projection inspection machine (the first profile projector)” that could inspect an enlarged image of the object to be tested. The machine was designed to carry out high-precision measurement, and contributed to the development of industry following various improvements.

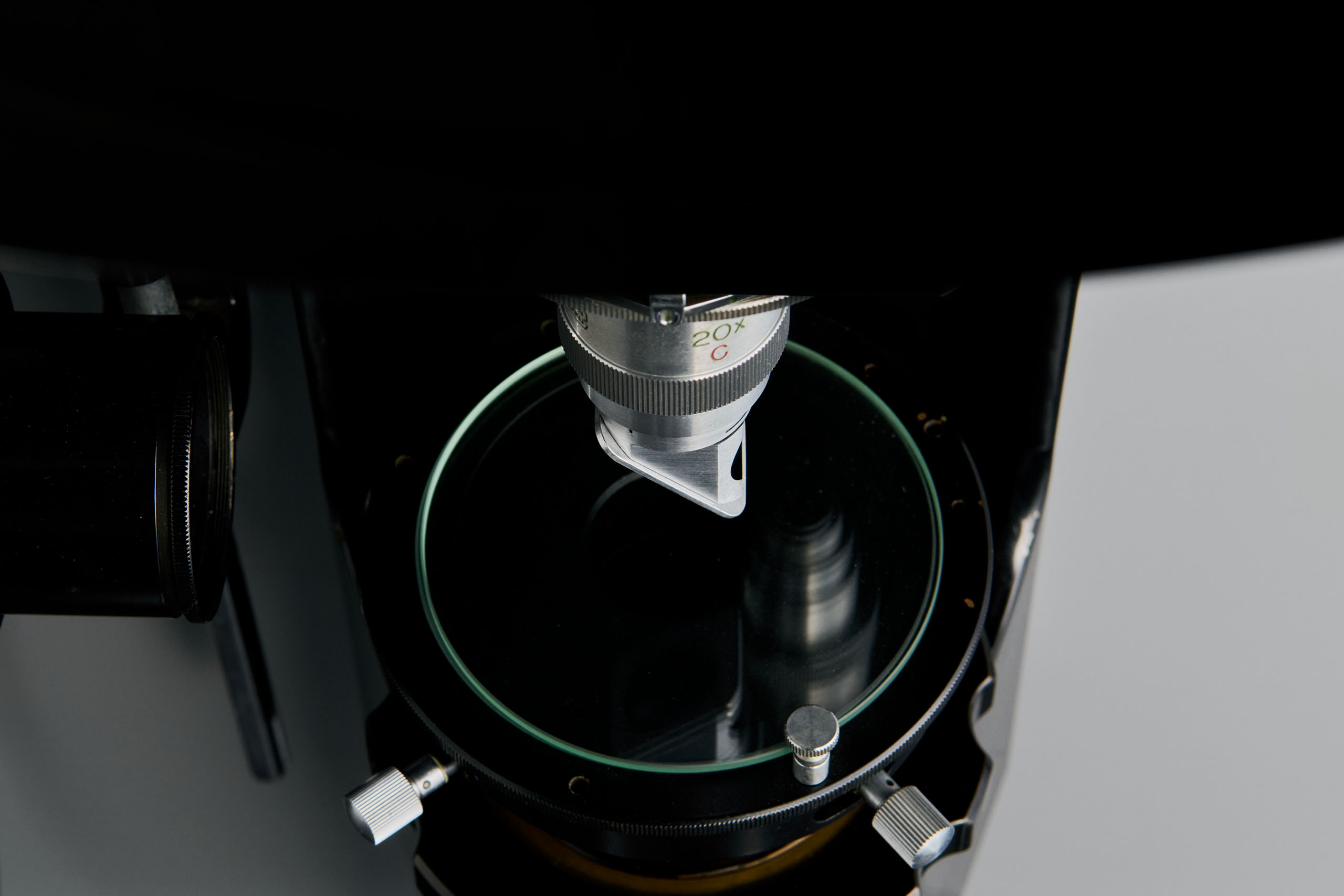

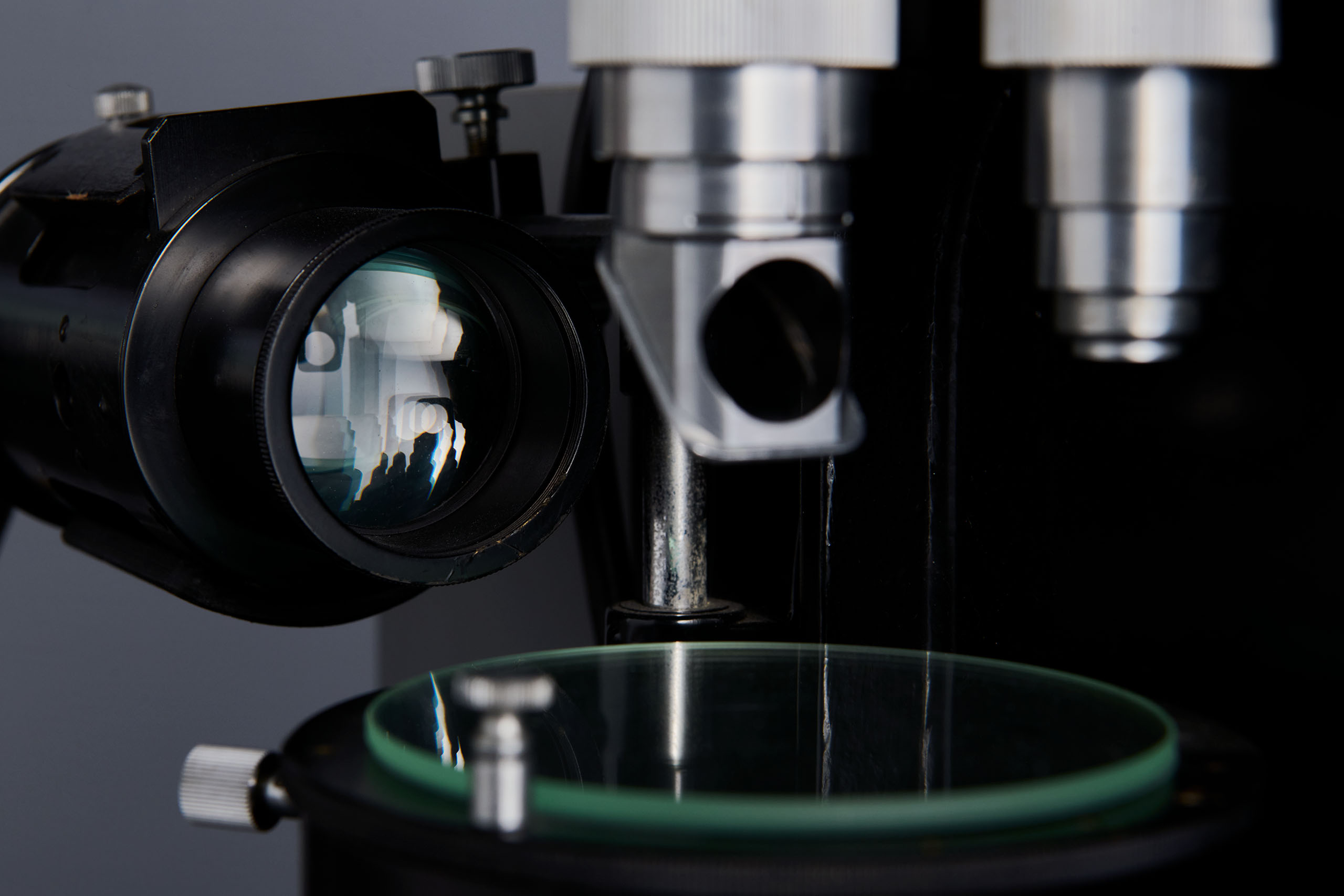

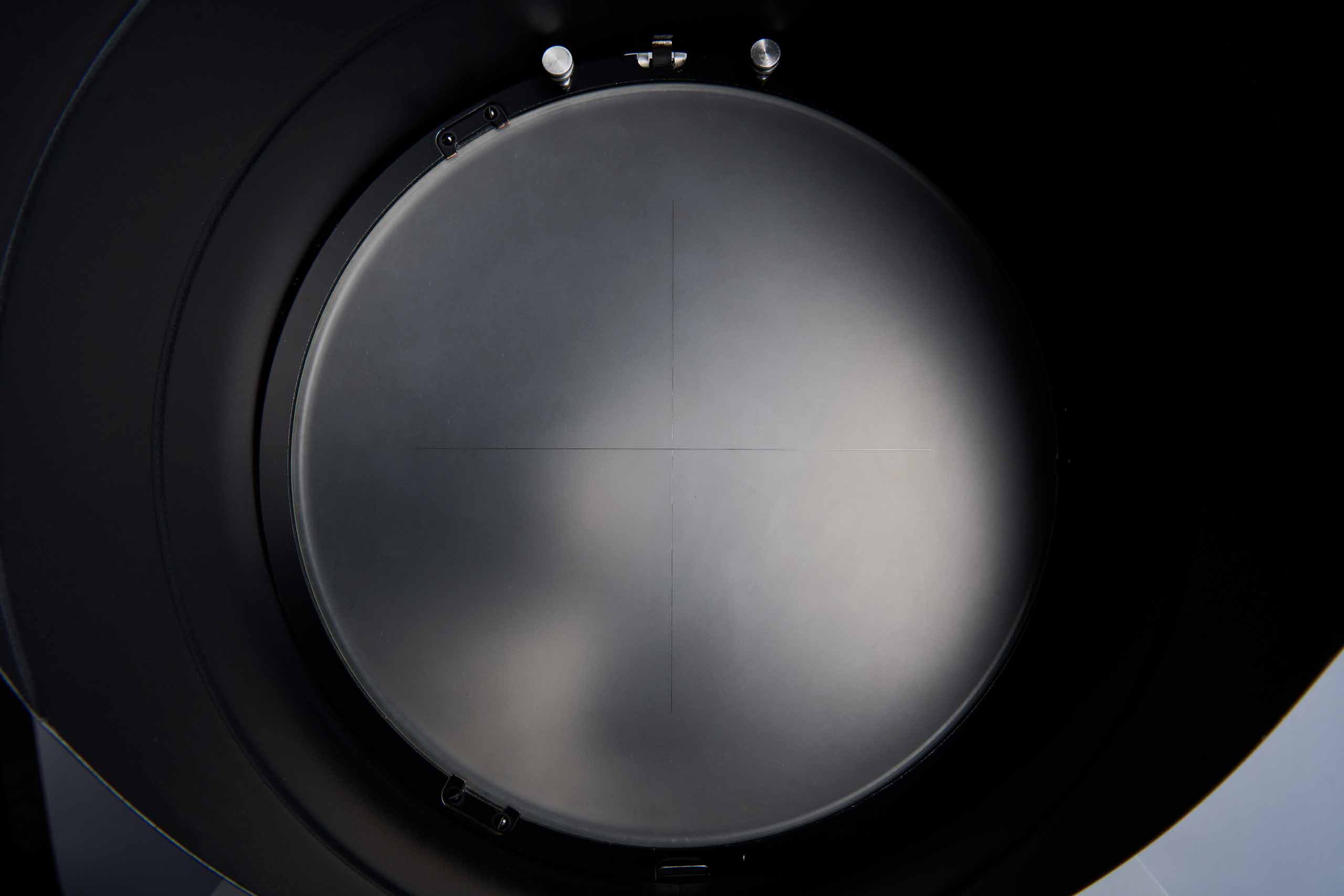

In the sense that it magnified small objects, it played a similar role to a microscope. However, since the profile projector projected the image of the observation subject onto a large screen, multiple people were able to check the projected image simultaneously.

This did not just optimize work efficiency. At manufacturing sites, people with various roles such as designers and quality control specialists work together to create products. By sharing images using a profile projector, any problems and improvement points in each process could be immediately investigated, leading to improved product quality.

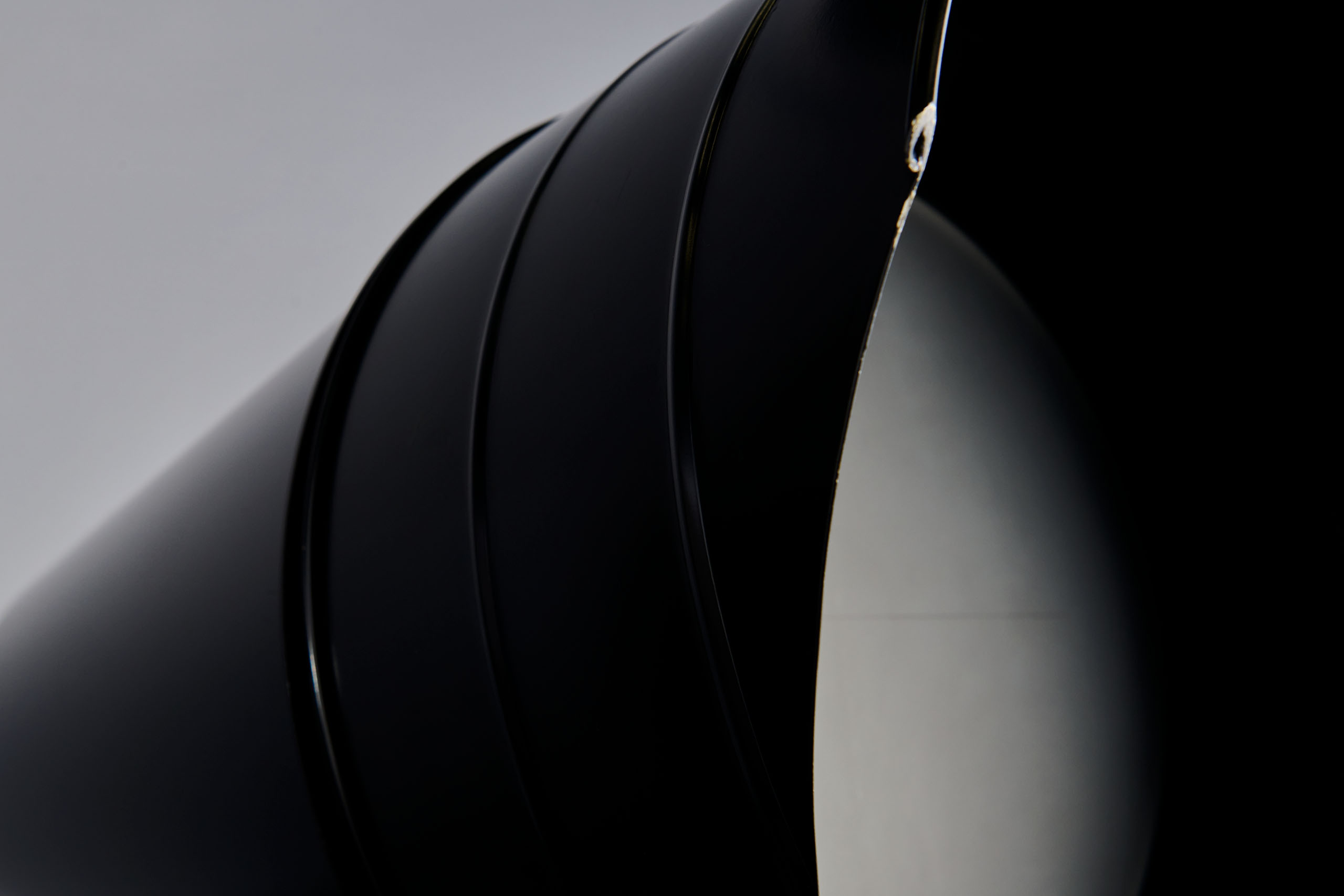

The images of the components that were enlarged and projected on the screen were surprisingly clear. It was as if the parts themselves were floating on the screen. However, in order to project such clear images without distortion, extraordinary technological backing was required.

The object to be measured is illuminated, and its image is projected onto a screen through a lens. Although this structure sounds simple, perfecting it concentrated the wisdom and ingenuity of engineers. The key was knowing exactly how to achieve the most accurate measurements. To discover this, they tackled the limits of optical technology.

The machine named “profile projector”

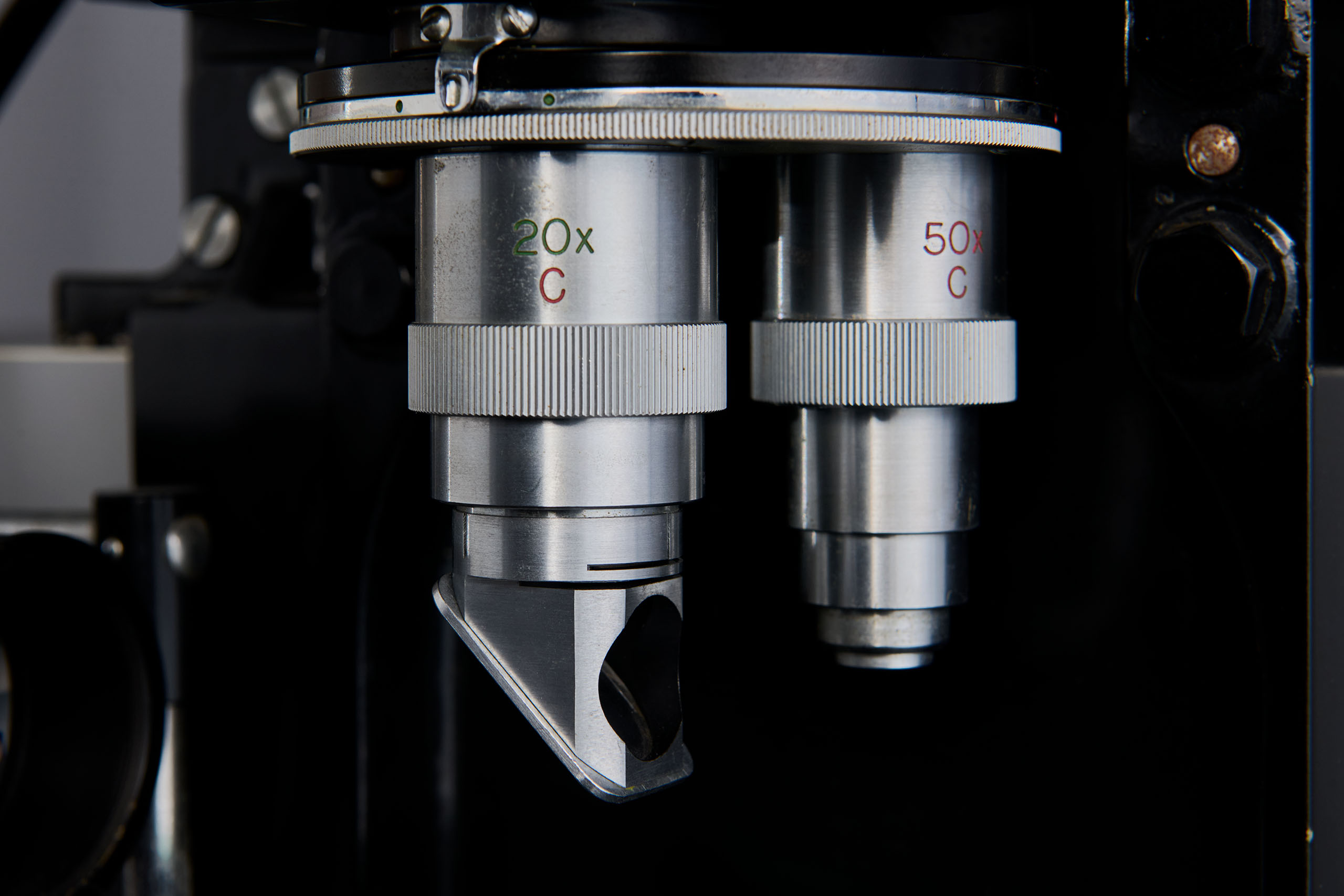

The profile projector, prototyped in 1939, was primarily used as inspection equipment within Nikon at that time. As industrial products became increasingly precise, the demand gradually expanded. Furthermore, by reviewing the design of the product and adopting a new optical technology that minimizes parallax, measurement accuracy had been dramatically improved.

However, it is said that during the reconstruction period, simply “manufacturing products” was prioritized and there was little interest in improving accuracy. Under such circumstances, gradually increasing demand from the precision machinery industry eventually supported the further improvement of profile projectors.

Initially, they were used mainly by watch manufacturers. However, later, functions were enhanced, realizing benefits such as higher magnification of the projection lenses, and upsizing of the stage on which the test object is placed, leading to the product’s usefulness being appreciated in unexpected fields. The applications were wide-ranging, including banknote identification by the Tokyo Metropolitan Police Department, oyster cultivation management at a fisheries research station, fossil morphology inspection for an oil company, and microbial research. Because of its high capabilities, it was named the “profile projector”.

Introduction of a telecentric optical system

The profile projector visualizes the minute details of the shapes of precision parts that cannot be seen with the naked eye, then measures them. It plays the role of an “eye” that creates “accuracy” supporting product quality.

The parallel beam illumination method employed in the optical system of the profile projector is also known as a telecentric optical system. In conventional optical systems, the magnification of an object changes depending on the distance from the lens, so nearby objects appear larger and distant objects appear smaller, but with a telecentric optical system, objects can be seen at the same size no matter how distant they are, as long as they are within the depth of field. This plays an important role in reducing errors in 3D measurement caused by parallax and achieving precise measurements.

Realizing more precise measurement in diverse fields

In addition, technologies other than optical systems were also progressing. The V-24B model, released in 1978, expanded the range of fields it could be used in, such as enabling electrical control of the vertical movement of the stage, making it easier to measure heavy objects.

Furthermore, data-processing equipment and measurement support software connected to the profile projector now assist people in their work, improving the measurement accuracy of the entire system.

The ”pursuit of precision”, which is Nikon’s DNA, has been inherited by the many varied product developments that Nikon has realized such as those for cameras, microscopes and semiconductor lithography systems. As a partner who will always be close to the manufacturing site, the passion Nikon showed when creating the profile projector has never faded.

Providing the “measure” that the era demands

As the manufacturing industry evolved with the times, the required level of accuracy also changed significantly. From the reconstruction period to the high economic growth period, Japan’s manufacturing industry achieved dramatic development. To effectively mass produce more precise and complex parts and products, high-precision measurement technology became essential.

Now, we are entering the era of a new industrial revolution. With advances through AI, IoT and robotics, manufacturing sites are undergoing major transformation. In addition, as semiconductor lithography systems known as the “staple product of industry” become smaller, nano-level precision is now also required.

Even amidst any changes across time, the crucial importance of “accuracy” remains constant. In fact, the need for even higher precision is increasing as technology advances. The technology cultivated through profile projectors has become a firm foundation that supports modern manufacturing.

Nikon has always pursued the highest precision in all fields. The underlying philosophy is the same “pursuit of precision” that went into the profile projector. Its existence not only supported industries in the past, but also serves as a universal “measure” to support manufacturing into the future.

Contents supervisor: WIRED JAPAN, Japanese text: Shuto Mizutani, Photography: Junpei Kato, Editing: Shinya Yashiro

Frontiers of Vision

- The NIKONOS all-weather camera: capturing the world in any conditions

- The profile projector: the unsung equipment supporting the precision of manufacturing

- The COOLSCAN: A “personal × digital” realm created by digitalization

- The JOICO microscope: The challenge of peering deeply into the world

- The COOLPIX 300: Pursuing the technological possibilities of a multimedia recorder

- The MIKRON 6×: Compact binoculars born over 100 years ago