History

Unravel more than 100 years of Nikon’s history and

explore future possibilities by visiting serial contents in collaboration with

WIRED, “Frontiers of Vision” that review a number of era-defining products,

and our “Corporate History” that relates the company’s history in chronological order.

Frontiers of Vision

Masterpiece review series

Nikon masterpieces and the future of applied optics and

precision technologies

Contents supervisor: WIRED JAPAN

Opening up new possibilities for applied optics and precision technologies…

Over the course of its long history, Nikon has pioneered the frontiers of vision in a variety of fields,

not confined only to the visual sense.

In this series, through reviews of various historical masterpieces that

Nikon takes pride in, we will find clues that point to our future direction.

Latest Article

No.9 | 1964 | In Pursuit of the "Ultrafine"

The Ultra Micro-NIKKOR: The Industrial Lens That Laid the Foundation for Japan's Semiconductor Industry

In 1964, a lens was born in pursuit of ultimate resolving power.

What began as technology for a specialized industrial application eventually became the foundation that helped Japan emerge as a semiconductor powerhouse.

Why did a lens designed to observe a tiny world gain the power to transform an entire industry?

Back Numbers

Into the Light. Nikon's First 100 Years

Corporate History

How Nikon has pursued, advanced,

and explored the possibilities of light for a century.

1917–

Aim for the light

Domestic Production of Optical Instruments and Original Manufacturing of Optical Glass

As Japan began to modernize in the

early 20th century, the challenge

was to catch up with Europe.

Developing Japanese industry was

the pressing need in every field,

and it was an especially urgent

issue in the optical industry where

high technology was crucial.

1917

1917

The origin of Nikon, as Nippon Kogaku K.K. was established

Nikon began as Nippon Kogaku K.K. (Japan Optical Industries Co., Ltd.) on July 25, 1917, at 120 Haramachi, Koishikawa-ku (present-day Hakusan 4-chome, Bunkyo-ku) in Tokyo, starting domestic production of optical instruments such as rangefinders and microscopes. This was the first of Nikon's many steps that now span a century.

During that era, the production of advanced optical instruments was a matter of national urgency for Japan. Entrusted with this objective was Koyata Iwasaki, the president of the Mitsubishi and nephew of Mitsubishi founder Yataro Iwasaki.

Hence, plans were made to establish an optics company by combining the optical instruments division of the Tokyo Keiki company and the mirror division of Iwaki Glass with Fujii Lens Manufacturing. This merger gave rise to Nippon Kogaku K.K. and, subsequently, the Nikon of today.

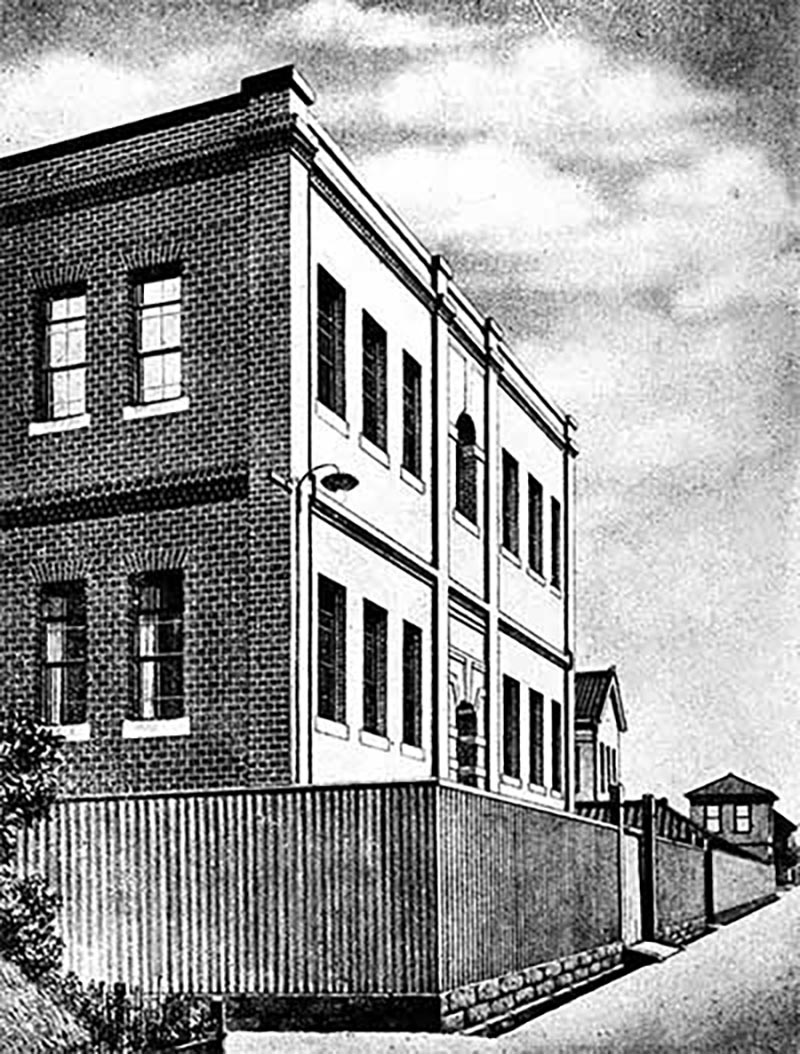

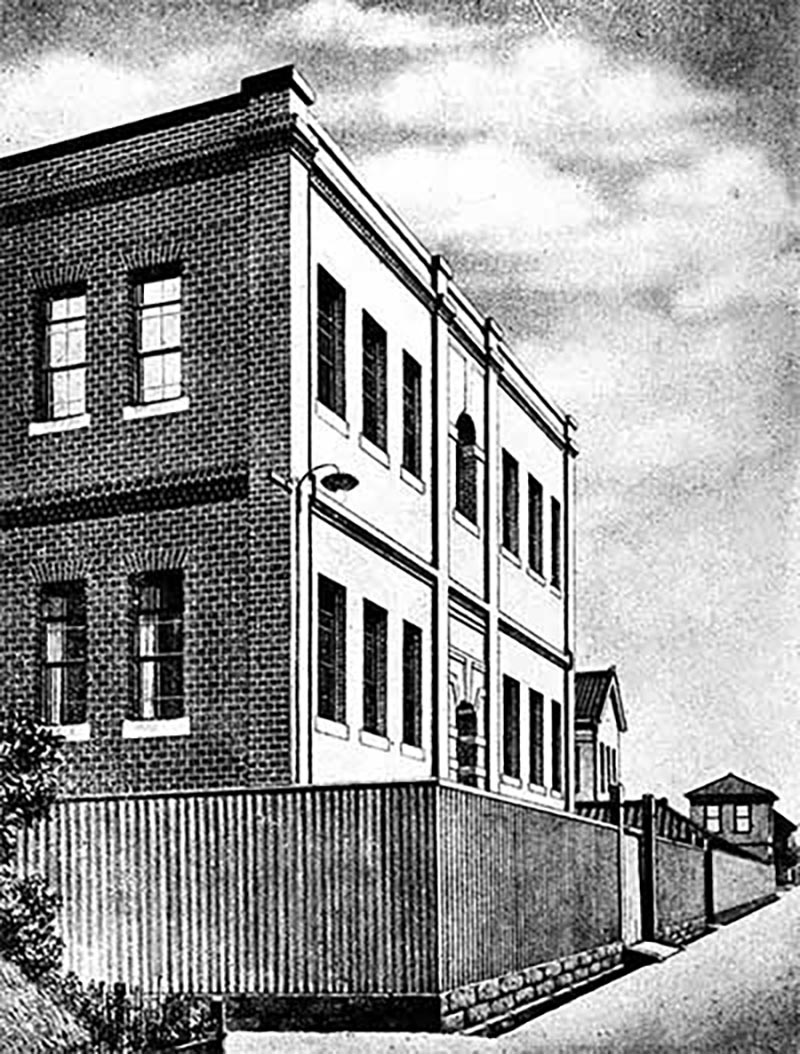

Nikon headquarters at the time was within the Tokyo Keiki company at 120 Haramachi, Koishikawa-ku, Tokyo (present-day Hakusan 4-chome, Bunkyo-ku).

1918

1918

Oi Dai-ichi Plant (now Nikon Headquarters) completed, and optical glass production started

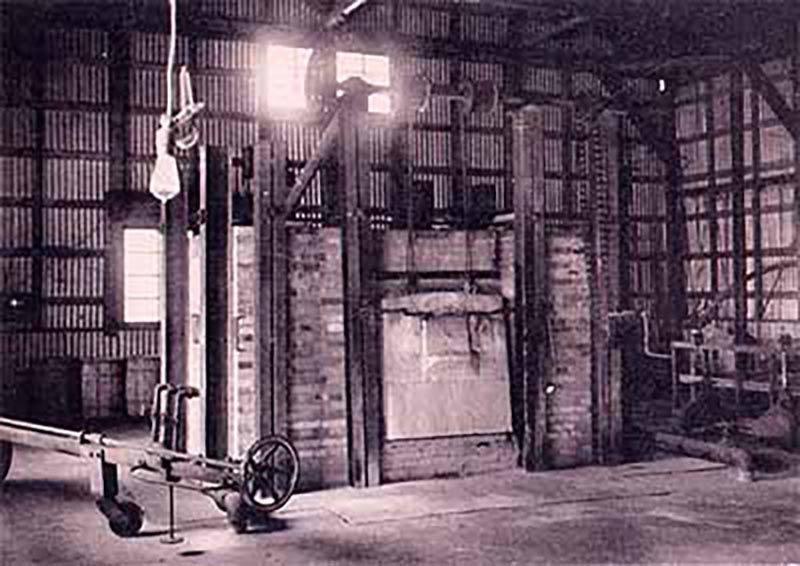

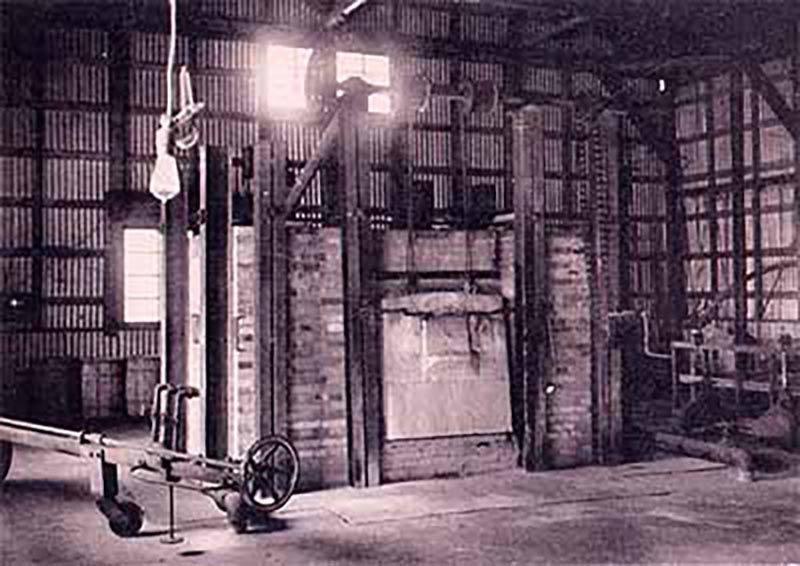

In 1918, the company began researching optical glass but suspended operations when it could not fully address several technical difficulties. However, in 1922, when self-sufficiency of optical glass to supply domestic production of optical instruments became a necessity, research was resumed in earnest. Thus, in March 1923, to enable parallel research of both the theoretical and the practical, the company built glass research facilities in three sections including the No. 1 melting wing in its Oi Dai-ni plant, and installed facilities including a 500kg melting furnace, four cooling kilns and two test furnaces (20kg and 7kg capacities). The company then began test-melting optical glass around May of the same year, and performed its first kilning using a 350kg crucible in June.

Oi Dai-ichi Plant in 1921. The tall building in the background is a five-story observatory.

1921

1921

MIKRON 4x and 6x ultra-small-prism binoculars are marketed

The 1921 MIKRON ultra-small-prism binoculars were one of the first binocular models developed, designed and manufactured by Nikon. They were acclaimed for their compactness and high functionality, and are still a popular model after having been reproduced for sale in 1948 and 1997.

One of the first binocular models developed, designed and manufactured by Nikon. It was reproduced in 1948 and 1997.

1921

1921

Inviting German engineers

With advances in optical technologies, eight engineers were invited by the company from Germany in 1921. These specialists included Professor Max Lange, who was a world authority on lens design, Heinrich Acht, who had rich experience in microscope design, Ernst Bernick, a leader in precision instrument technology, and Hermann Dillmann, a specialist in lens design and computation. The guidance of these engineers had a dramatic effect on improving the company's technologies.

They also initiated design for development of Nikon's photographic lenses. To catch up with the level of optical technologies of developed countries, the company started out by imitating, and named its series of lenses "Anytar," which were designed following the example of the Tessar lens that was the main lens type at the time. Heinrich Acht, who was the director of the mathematics section of the design department was placed in charge of the Anytar lens designs. It is said that Acht had a hand in almost all of the Anytar lens designs.

The Japanese designers made improvements after Acht returned to Germany. The Anytar 12cm F4.5 prototype was initially completed in 1929. It was then further modified, and by 1931 reached a level where it was no longer standing in the shadow of the original Tessar. It is recognized that there have been seven types of the Anytar lens, with focal lengths of 7.5cm, 10.5cm, 10.7cm, 12cm, 15cm, 18cm and 36cm.

Front of the Anytar 12cm F4.5

1925

1925

JOICO Microscope is marketed

Nikon has been involved in the development of the microscope since its founding, and microscopes are listed as production items in its articles of incorporation. Pouring efforts into development of the microscope, one of the specialists brought in from Germany was Heinrich Acht, an engineer with rich experience in microscope design. Acht was active in the design of microscope objective lenses, and improved lens precision by adopting and improving on new German-style systems. By bringing these efforts to fruition, the company released its JOICO Microscope in 1925. With its 765x magnification this instrument was a groundbreaking microscope for its time.

The first microscope designed by Nikon. The trademark JOICO was from the initials of Japan Optical Industry Co., a translation of Nippon Kogaku K. K., the company's name at the time.

1927

1927

Established the mass production of optical glass

In September 1923, the company's glass research facilities were damaged in the Great Kanto Earthquake and their operations had to be suspended. Recovery was completed by February of 1924, and glass research was then resumed. By March of 1927, 70 major melts and 220 trial melts had taken place. The purpose of these efforts was solely to improve glass quality and establish mass-production technology.

Meanwhile, for basic research, the company also set up an analysis laboratory in its Oi Dai-ni plant to determine basic specifications for glass materials and perform analysis on glass and crucible clays. Research into precision glass annealing was also begun, with a furnace built in the corner of a hallway to measure changes in test glass distortion. The first attempt made was to anneal a 20cm-diameter objective lens for a large binocular telescope and in 1927 successful annealing of glass for rangefinder pentaprisms was achieved. Through such research and much hand work, the company became able to manufacture optical glass of a quality equal to that made outside of Japan.

1931

1931

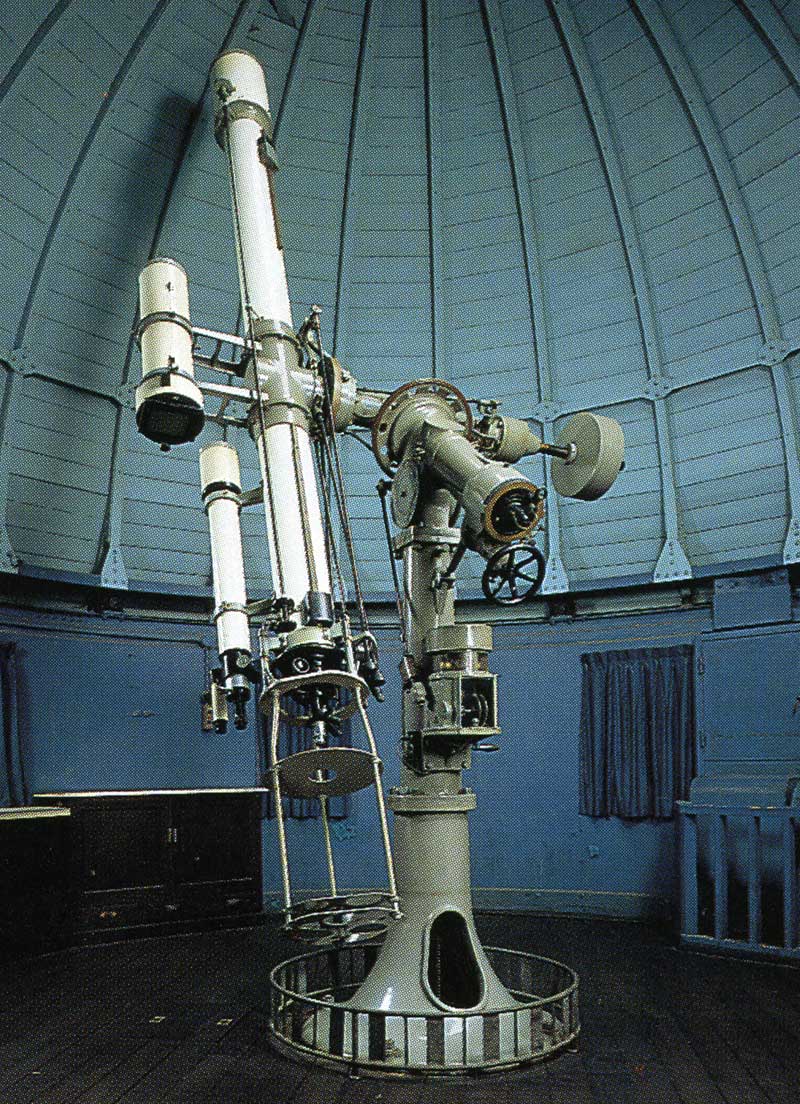

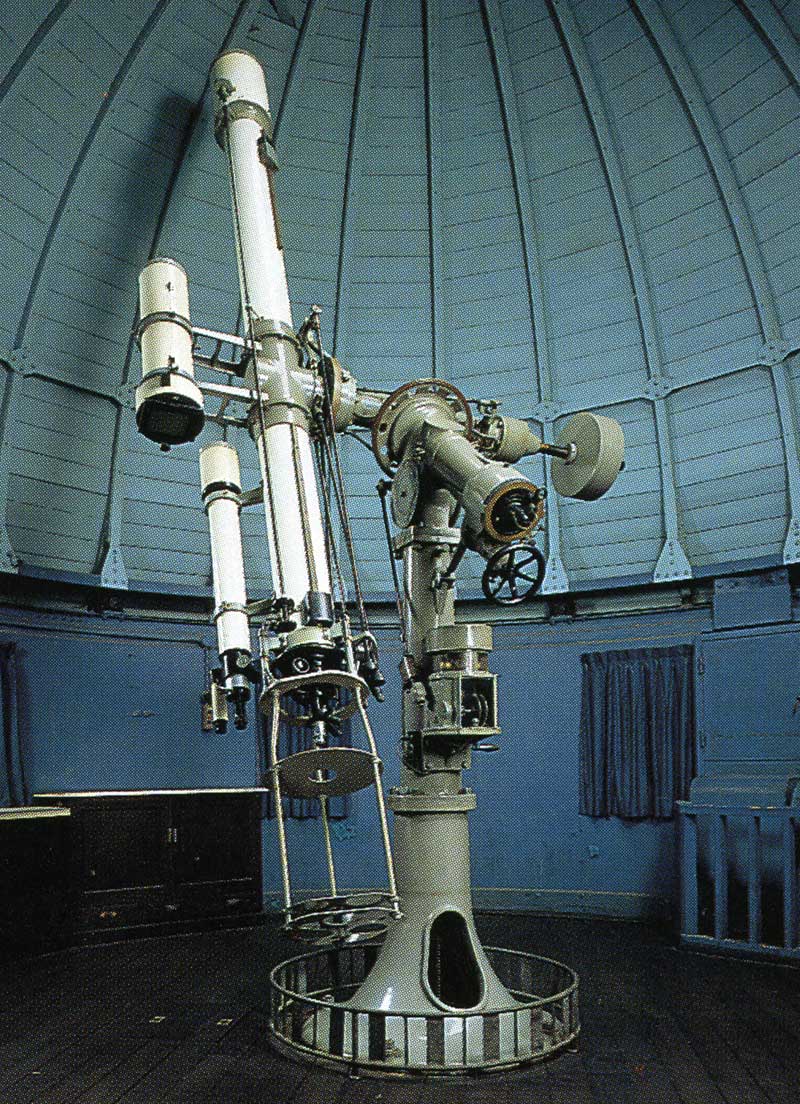

An 8-inch astronomical telescope is installed at Tokyo Science Museum (today's National Museum of Nature and Science)

In 1931, an 8-inch astronomical telescope was installed in the roof observatory dome on the newly completed Ueno wing of the Tokyo Science Museum. This was known as the 20cm equatorial refracting telescope and was the first full-fledged model of its kind to be produced in Japan. It boasted the largest caliber compared to other Japanese-made telescopes of the time. The device underwent major modifications in 1954 and continued to convey the fascination of the heavens to visitors for a total of over 70 years, the longest ever in Japan, until 2005. The telescope is now on permanent display in a zone called the Exploring the Universe located on basement level 3 of the Global Gallery at the National Museum of Nature and Science.

Nikon's first equatorial telescope had the largest diameter of any such telescope in Japan at the time. It remained in use until 2005.

Cooperation: The National Museum of Nature and Science

Cooperation: The National Museum of Nature and Science

Cooperation: The National Museum of Nature and Science

1932

1932

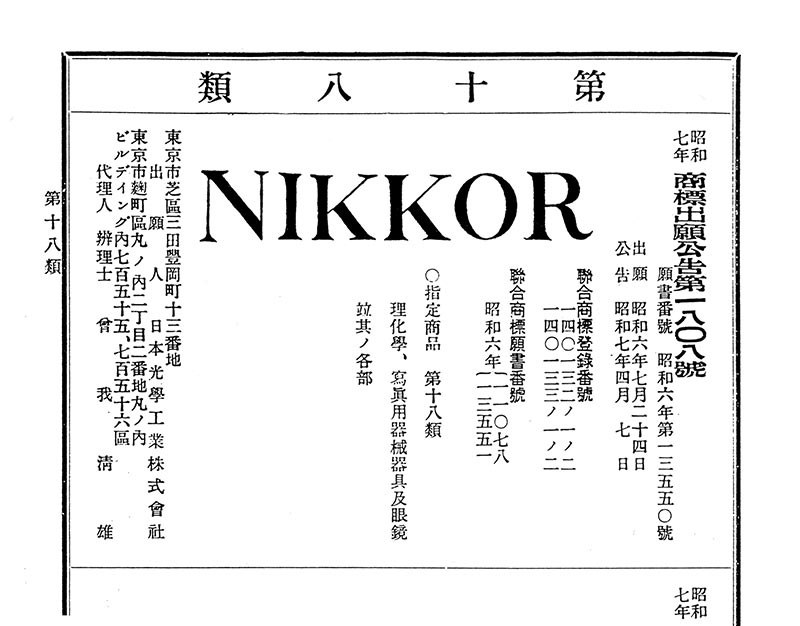

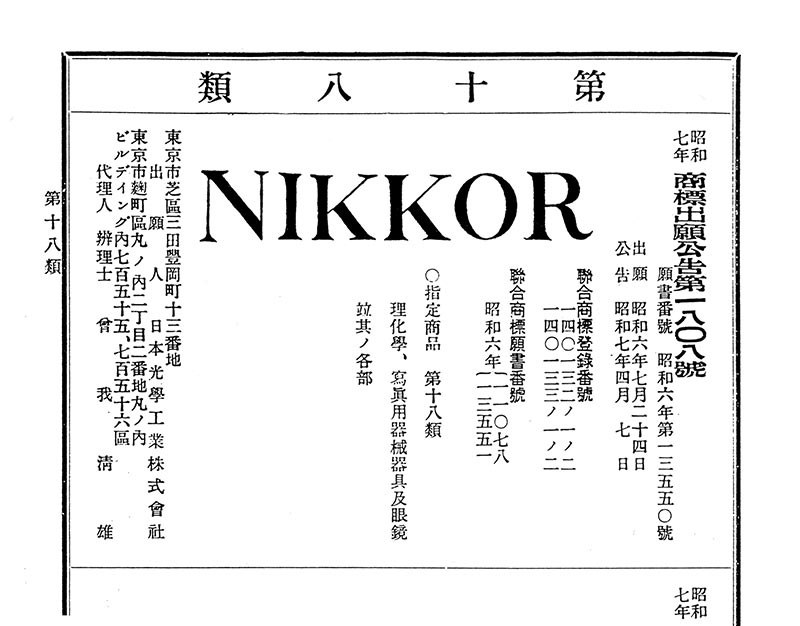

NIKKOR is adopted as the brand name for camera lenses

NIKKOR lenses were born of the strong desire of Japanese designers to domestically produce photographic lenses, for which the nation had up till that point been reliant on other countries. Designers went to Europe to observe its optical industry, and devoted their time to gathering information on photographic lenses, visiting camera store after camera store in Berlin. Finally, after obtaining samples, the designers returned to Japan, which is when the real struggle began.

Although modern computers can now be relied upon, lens design involves various complex calculations. Even painstakingly produced prototypes might not provide the expected image quality when used to shoot photographs, and compared to the current era, there were far fewer types of glass available for lenses. The company engaged in research by means of disassembly, measurement and assembly experiments following precision aberration measurement testing.

After these exercises in trial and error, the company produced its first lens in 1929, the Anytar 12cm F4.5. Then followed the successful development of a range of lens models, while considering a brand name for these products, as there were now definite prospects for photographic lens manufacture. Hence, combining the "NIKKO" abbreviation of the "Nippon Kougaku" company name with the letter "R" often used as a suffix for photographic lens names at the time, the company settled upon the NIKKOR brand name. This name was registered as a trademark in 1932.

Publication of the NIKKOR trademark application. It was filed in July 1931, published in April 1932 and registered in December 1932.

1933

1933

Delivery of Aero-NIKKOR, a NIKKOR lens designed for aerial photography

NIKKOR lens history began in 1933 with the delivery of lenses designed to be used in aerial photography for map-making. These lenses were thus called "Aero-NIKKOR" with the prefix indicating their intended aerial purpose. The company first supplied NIKKOR lenses including a 70cm F5 and an 18cm F4.5 for compact aerial photographic applications.

From its historic beginnings, the NIKKOR range has continued to develop, and has grown to become synonymous with Japan's leading high-performance lenses.

One of the few Aero-NIKKOR 50cm F4.8 lenses still in existence

1946–

Reaching out around the world

Becoming the Comprehensive Optical Instrument Manufacturer of the World

As Japan experienced postwar restoration and growth at miraculous speed, many of its products were disseminated to the rest of the world. Nikon's optical equipment performance was highly evaluated, and played an important role in creating world recognition for the new, superior quality of "Made in Japan".

1946

1946

Pointal ophthalmic lens is marketed

1946

1946

Nikon brand name is adopted for small-sized cameras

When deciding what to call a compact camera developed to meet the strong demand for domestically produced cameras, the company came up with the tentative name "Nikorette" to express compactness while building on the "Nikko" abbreviation of its Nippon Kogaku name at the time. However, due to opinions that this was a weak-sounding name for a product destined to be a major future player, the company used the Nikko base and added an N to the end which creates a more masculine impression in the Japanese language, and thus the official Nikon name was born.

1947

1947

Tilting Level E and Transit G surveying instruments are marketed

These surveying instruments were Nikon's first products after World War II. On the left is Tilting Level E and on the right is Transit G2, which was an upgrade of Transit G and released in 1949.

1948

1948

Nikon Model I small-sized camera is marketed

Less than two years after the completion of blueprints in September of 1946, the first Nikon camera, the Nikon Model I, was launched in March of 1948. This camera contained original inventions such as small radial ball bearings used for the shutter release, and was the result of overcoming many tough challenges, from research through to marketing.

The Nikon Model I was highly anticipated after being advertised in magazines and via other channels before its release. At the time, supply could not keep up with the strong demand for domestically produced cameras, but the real battle began the moment the camera went on sale. Designers had to field complaint after complaint, and find effective solutions on a daily basis. Nevertheless, they overcame issues one by one and made improvements leading to the Nikon M model of 1949 and the Nikon S of 1950. After that, the camera continued to evolve into the S2, SP, and to the single-lens reflex Nikon F. Nikon cameras advanced continually until their robustness and sophistication went on to attract renown, making Nikon a global brand.

The first Nikon camera and the first product to bear the "Nikon" name. It was first sold as "Nikon", but "Model I" was added to the product name to distinguish it from subsequent cameras.

1948

1948

Model I profile projector is marketed

A profile projector redesigned from an in-house-use model to incorporate the parallel beam illumination method and other features.

1950

1950

The New York Times introduces the superior features of Nikon cameras and NIKKOR lenses to the world

On December 10, 1950, the New York Times published a special article commending the excellence of Nikon cameras and NIKKOR lenses. This was based on high acclaim by LIFE magazine photographers who had traveled to the Korean War battlefields. On the bitterly cold Korean Peninsula, while other cameras were frozen and unusable, Nikon's worked well and recorded how the severe battles were fought.

The New York Times article reported that, "NIKKOR lenses are extremely precise, with high efficiency, and better than German lenses" and "Previous Japanese cameras had only beautiful exteriors, while internal performance was inferior, however, this Nikon camera is intricate and provides beautiful results."

Because of this, NIKKOR lenses which were equal to German lenses pre-war, achieved the world's highest class and completely renewed the image of "Made In Japan" which had previously been "cheap and bad quality". As a technology-intensive nation, Japan started here.

1952

1952

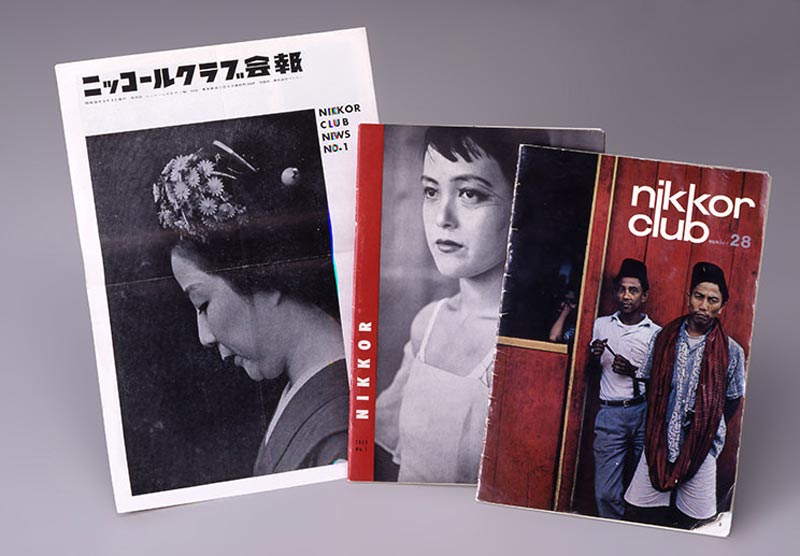

Nikkor Club is established to promote photography culture

Having been highly acclaimed and relied on by Life Magazine photographers, NIKKOR lenses became a favorite of prominent photographers around the world. While interest in Nikon and NIKKOR was also growing among amateurs, the Nikkor Club was founded as an international association for friendly exchange among keen users of NIKKOR lenses.

Founding members included international photographers from Life Magazine and Magnum Photos, top photographers from Japan, novelists, scholars and film actors.

Nikkor Club was established with the help of Ihei Kimura, Ken Domon, Jun Miki, Yusaku Kamekura, Kenji Mizoguchi and Hideko Takamine. The photo shows copies of the newsletter that was first published in 1953. The first issue is in the middle.

1954

1954

Model SM stereoscopic microscope is marketed

The model SM stereoscopic microscope was the only product of its kind in Japan at the time that featured a built-in three-step variator, which prevents focus drift during zooming, and epi-fluorescence illumination.

1957

1957

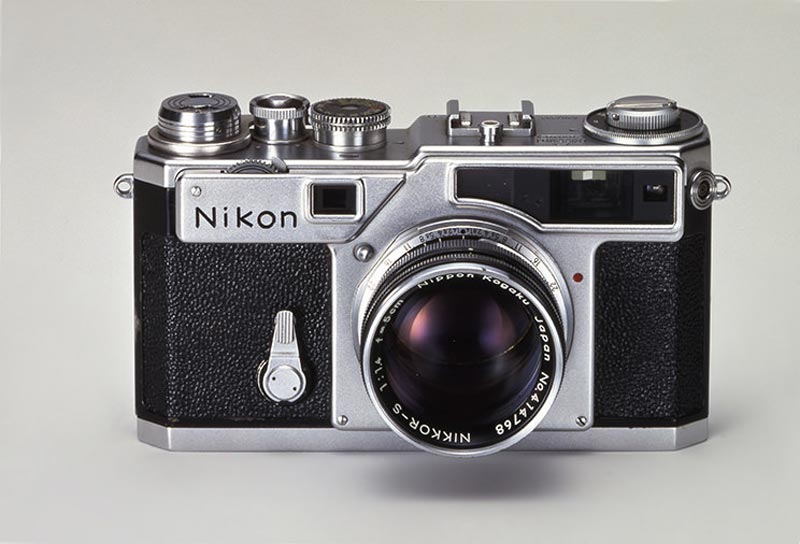

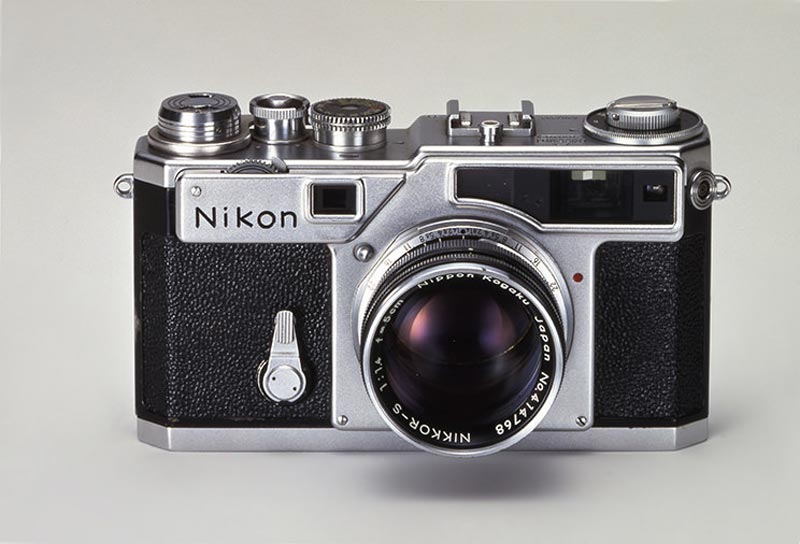

Nikon SP rangefinder camera is marketed

The signature and legendary Nikon SP was a ship of rangefinder cameras made in Japan.

The most important feature of this camera, a built-in universal viewfinder that supports six interchangeable lenses (focal lengths 2.8, 3.5, 5, 8.5, 10.5, 13.5cm) was highly acclaimed by professional photographers. These cameras were prized for their whisper-quiet curtain shutters, rear curtain accelerator and silent braking to absorb shock (with coiled axial clamping), as they were designed to produce extremely low operating noise and shock. These technologies began to develop into a system camera with a motor drive unit (capable of 3 frames per second), finder frame illumination for dark locations, and a flash sync connection in the accessory shoe, all directly connectable without a cord. Nikon's first self-timer was also built in.

The Nikon SP, together with the NIKKOR lens and optical glass, won the grand prix at the 1958 World Expo held in Brussels.

35mm rangefinder camera, Nikon SP

1959

1959

SLR camera, the Nikon F is marketed

Bringing together Nikon's optical and precision technology, the Nikon F drew a major reaction from around the world, and was in production for 15 years up to 1973, effectively solidifying the Nikon and NIKKOR brands.

Newly developed were main components such as the mirror box, pentaprism and bayonet, while the rest could be said to be the same as the SP. However, major technical hurdles had to be surmounted in developing the mirror box and pentaprism mechanism, such as the need for the mirror and lens aperture to automatically return to the wide-open state instantly after shooting.

The bayonet mount was made of stainless steel to sufficiently withstand the weight of a telephoto lens. Looking ahead to the future, a 44mmø (34mmø for the Nikon S) internal diameter was also adopted to enable use of larger aperture lenses. This was the "Nikon F mount" which is also used with new digital single-lens reflex cameras – a technology that has been handed down for more than half a century. This system is the world's longest used lens mount originally designed for 35mm SLR cameras.

The Nikon F takes full advantage of the SLR characteristic of being able to actually project onto the film what the user sees in the viewfinder by making the finder's field of view 100%. Titanium (0.02mm thick) was adopted for the shutter curtain. In addition to shutter speed, a complete coupling system combining aperture with the Nikon exposure meter was achieved.

Nikon's first lens-interchangeable SLR camera. It established a strong presence as a high-end SLR camera.

1962

1962

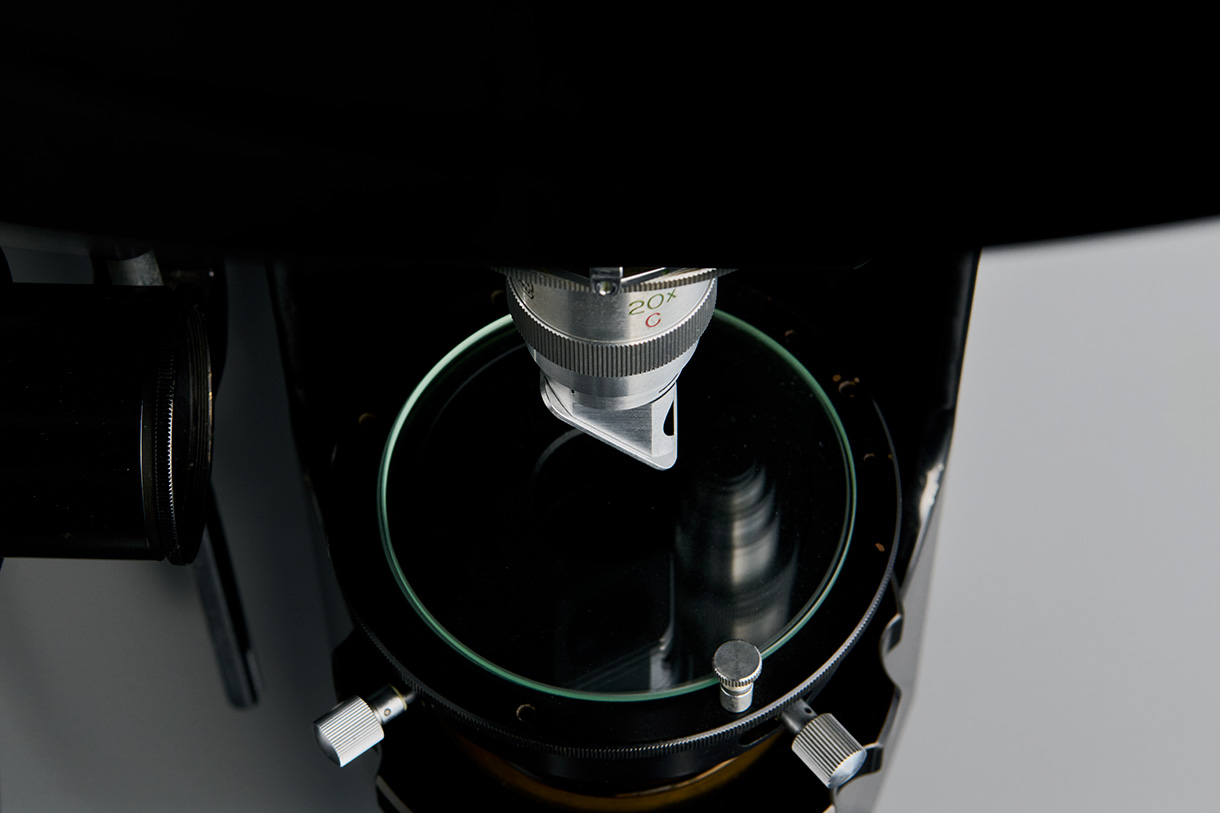

Ultra Micro-NIKKOR high-resolution optical lenses are marketed

After the war, Japan had deployed an American micro-file system for saving bulk documentation on microfilm, but because many more strokes are required for writing Japanese characters than the alphabet, the lens resolution of the system was insufficient. Hence, the company developed the high-resolution "Micro-NIKKOR" lens in 1956, which resulted in a flood of inquiries from printing companies and electronics manufacturers about high-resolution lenses. There were also demands for higher-resolution lenses to be used for creating the printed circuit boards required for the manufacture of electronic components.

Thus, in August of 1962, the Ultra Micro-NIKKOR was developed. Two years later, the company succeeded in developing a lens boasting the highest resolution of any in the world. With this resolution it was possible to distinguish some 1,260 paired black and white stripes per millimeter. A 330-page English novel was successfully compressed onto a microfilm just 12.6 x 13.2mm in size – the Ultra Micro-NIKKOR took both the Japanese and global markets by storm.

Subsequently, the technological legacy of the Ultra Micro-NIKKOR would be inherited as the core technology of semiconductor lithography systems, which would be called "the most precise machinery in history."

Developed for the production of photomasks required for photolithography. The lens had the highest resolution of any lens at the time.

1963

1963

NIKONOS all-weather camera is marketed

Designed to be water-/pressure-/corrosion-resistant, and positioned as an amphibious "All Weather" camera.

1964

1964

Ruling Engine No. 1 is installed at the Tokyo University of Education

The first ruling engine in Japan. Until the 1960s, it was known as the "fantasy machine," as the ultrahigh precision required for its manufacture was extremely difficult to achieve.

1968

1968

Photo gallery Ginza Nikon Salon is opened

Established with the aim of boosting Nikon's corporate image and the culture of photography. The first exhibition was "The Eyes of Ihei Kimura (celebrated Japanese photographer)." (Osaka Nikon Salon was opened in 1974)

1968

Rotary encoder RIE digital measuring instrument is marketed

1969

1969

Call for entry for the 1st Nikon Photo Contest International (now Nikon Film and Photo Contest)

The Nikon Photo Contest International started as an international photography contest promoting interaction between both professional and non-professional photographers with the aim of contributing to the development of photography culture. The first time the contest was held it attracted more than 21,000 submissions from 37 countries around the world. Since 1974, Nikon Calendar photos have been selected from these submissions. The name of this historical competition was changed to “Nikon Photo Contest” for the 34th contest in 2012, and then to “Nikon Film and Photo Contest” for the 40th contest in 2024, in response to various changes over time, such as the diversification of media and an increase in opportunities for individuals to share videos. The contest continues to evolve to discover new perspectives and create new opportunities.

1971

1971

Nikon Photomic FT Nis mounted on Apollo 15

In January 1971, Nikon agreed a contract in response to a request from the American National Aeronautics Space Administration (NASA). This was to supply cameras to record the Apollo 15 mission to the lunar surface to be launched that year, and for the Apollo 17 mission planned for the following year. The 1968 Nikon Photomic FT Nwas selected as the base for the development.

NASA had designated specifications to ensure that these cameras would function correctly in the extreme environments of space. These included use of NASA-specified materials such as lubricants and high shock absorption characteristics, and to prevent possible problems due to the reflection of sunlight, the exterior of the devices were to be matte black. 55mm F1.2 lenses were mounted, also finished in matte black. By June, all of these criteria had been satisfied and the company supplied NASA with nine cameras. These products were headed for the moon the following month with the launch of Apollo 15. The NASA-specification Nikon Photomic FT Nwas also later adopted as a special camera system used in Skylab, a mission during in which three astronauts lived in space over a prolonged period. The cameras were designed to photograph the Earth's ozone layer and Auroras.

Based on "Nikon Photomic FT N," modifications were made to specifications and materials, such as lubricating oil, based on special requests from NASA.

1971

1971

MND-2 extra-long-distance meter is marketed

Developed jointly with Mitsubishi Electric, this instrument made it possible for the first time in Japan to measure distance using light waves.

1971

1971

Nikon F2 is marketed

The Nikon F2 aimed for easier operation, faster shooting and more automation while maintaining "F" compatibility with interchangeable lenses and accessories. The camera featured improved functionality and refined details such as a reliable 1/2000 second high-speed shutter for the professional photographer use, a 2-10 second slow shutter utilizing a self-timer mechanism, a large-size mirror, hinged rear-lid and a more convenient shutter button position.

1971

1971

Development of Extra-low Dispersion (ED) Glass

ED Glass is a special glass designed to compensate for chromatic aberration and achieve clearer images.

Compensating for chromatic aberration of the lens usually entails correcting the focal points of two different wavelengths so that they match. However, with telephoto lenses in particular, there are more than two wavelengths involved which means the amount of focal deviation (secondary spectrum) is larger and there is more chromatic aberration which degrades image quality.

Low-dispersion glass was shown to be effective in solving this problem, so the company began its manufacture. In December 1971, the company developed a new type of optical glass called PC102 ED Glass. Taking the lead over other companies, Nikon achieved upsizing and mass production with a continuous melting process.

In January 1972, the company released the NIKKOR-H 300mm F2.8 aimed at the press, which was used to shoot various competitions at the Sapporo Olympics. PC 102 improved lens performance and was adopted for the 300mm and longer telephoto and zoom F-mount lenses, although it missed the initial production of this lens.

Beginning with interchangeable lenses, ED glass is currently also utilized for binoculars, Fieldscopes and a derivative glass is employed for semiconductor lithography projection lenses. To put it simply, this material has become indispensable to Nikon products.

NIKKOR-H 300mm F2.8 used ED glass for the first time

1971

1971

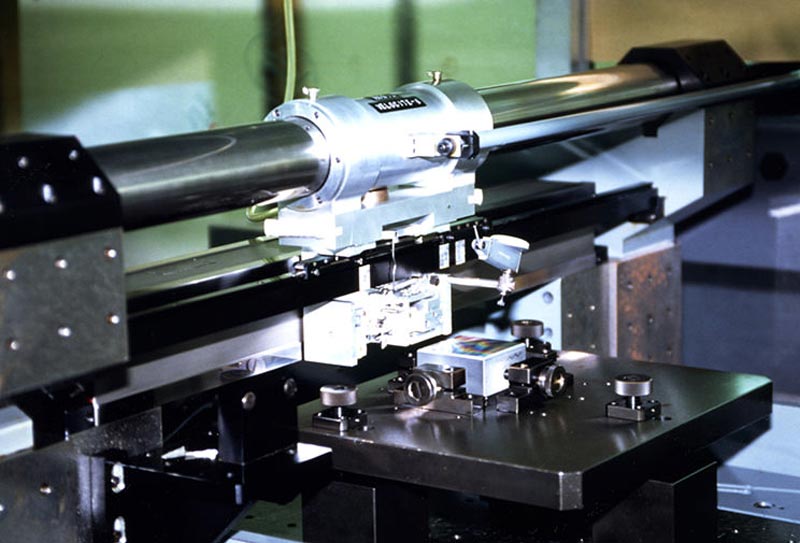

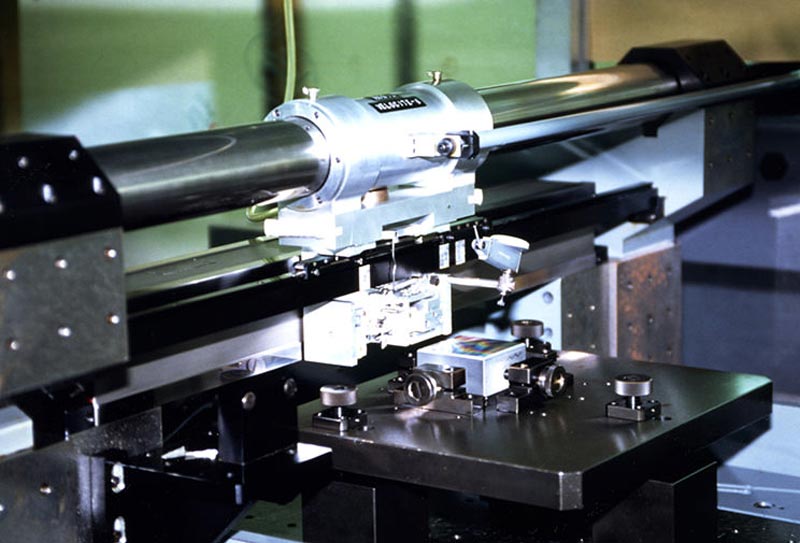

Ruling Engine No. 2 is completed

A ruling engine refers to a diffraction grating ruling machine, and is a device for manufacturing diffraction gratings.

In 1964, Nikon completed Ruling Engine No. 1, the first domestically produced ruling engine as a part of Ministry of Education projects (currently the Ministry of Education, Culture, Sports, Science and Technology). However, the device was not practical due to accuracy and stability issues. Even later in the 1960s, the ruling engine was considered more of a theoretical "fantasy machine" than a reality in Japan.

Around this time, Nikon was considering new business with spectroscopic analysis machines. Diffraction gratings are key parts of spectrum analyzers. They are optical components that consist of fine structures on glass or mirrors to provide spectra from the interference of light diffracted as it passes through the grating. The company became aware of the need for the ruling engine.

Nikon began developing its second ruling engine in 1967. While basic parts were outsourced due to budgetary and time considerations, Nikon moved ahead with the development of a control system for the glass substrate stage and its laser interferometer. Nikon also worked on various developments such as diamond cutter polishing technologies and replica production technology for mass production of diffraction gratings. Ruling Engine No. 2 was completed in 1971, and Nikon began mass production of the 2-inch square diffraction gratings to be mounted in the "Nikon monochromator G-250" spectrum analyzer. Thus, the "fantasy machine" had finally become a reality.

The achievement of Ruling Engine No. 2 gave Nikon a big boost toward developing semiconductor lithography systems.

Ruling Engine No. 2

1976

1976

Biophot and Metaphot microscopes are marketed

The world's first successful commercialization of a microscope objective lens for the CF system. The system was referred to as "the first innovation in 100 years." The photo shows a Biophot microscope.

1977

1977

Development of the Nikon F2 Titanium Uemura Special

Naomi Uemura was one of Japan's leading adventurers. Among his many accomplishments, he was the first Japanese to reach the summit of Everest, first in the world to climb the highest peaks on five continents, circumnavigate the Arctic Circle and reach the North Pole solo by dog sled, for which he was awarded the People's Honor Award in 1984.

On arriving in Alaska on his 12,000-km solo dog sled trip around the Arctic Circle in May 1976, Uemura was greeted by news photographers. Nearly all the cameras pointed at Uemura were Nikons. In such a harsh environment many other brands of cameras failed and were not able to record the moment.

In June 1977, Uemura expressed his desire to Nikon for a camera to take on his solo dog sled trip to the North Pole. Such a camera would have to withstand heavy shock and the extremely low polar temperatures. For this reason, the drive system was lubricated with special cold-resistant oil, and the shutter speed was adjusted to function properly in temperatures around minus 50°C. The camera was retrofit with titanium for the top, bottom, penta and front cover parts. At the time, Nikon was the only company able to manufacture titanium camera parts. A prototype was put in the trunk Uemura used on his dog sled, and tested for shock by rolling it down some stairs at the company's Oi plant.

This resulted in the world's first titanium-exterior SLR camera in December 1977, called the Nikon F2 Titanium Uemura Special, of which three units were completed. The following year, Uemura headed across Greenland on his solo dog sled trek toward the North Pole with two cameras, and shot 180 rolls of film of the six month adventure.

In 1982, the Nikon F3 Titanium Uemura Special, based on the Nikon F3, was manufactured for his 3,000-km Antarctic dog sled trek and scaling of the Vinson Massif, the highest peak on the Antarctic continent. But due to the Falklands war in March of that year the trip was canceled and the cameras were not used on an expedition.

(With the cooperation of the Uemura Museum Tokyo and Uemura Naomi Memorial Museum)

A self-portrait of Naomi Uemura using a self-timer. A shadow of the camera is visible on his thigh.

Photo courtesy of Bungei Shunju

Photo courtesy of Bungei Shunju

Photo courtesy of Bungei Shunju

1980–

Leaping ahead of the times

Expansion of Business Domains, the Challenge of Digital Technologies

Computers and communications made great progress, and this turbulent period drastically changed people's lives, industries and society.

With technological innovations brought about by optical and ultraprecise technologies, Nikon continued to strongly support the foundations of digital society.

1980

1980

Nikon F3 SLR camera is marketed

As a flagship model, the latest electronic technologies of the day were adopted for the Nikon F3. This was the first camera to offer electronic shutter control and an aperture-priority auto-exposure control mechanism. The F3 also featured new functions like an LCD viewfinder display, a TTL sensor positioned at the bottom of the camera mirror box, and Speedlight TTL flash control. The F3 was not equipped with a motor drive, but the optional motor drive was designed to work as an integral part of the camera body to achieve shooting at up to 6 fps. Both the camera and motor drive were designed by Giorgetto Giugiaro of Italy. He designed the two to appear as one when the motor drive was attached to the camera. Giugiaro's fresh design pursued a simple form featuring a raised grip on the camera body, and an eye-catching red line. These design elements had a great impact on later camera designs.

The Nikon F3 was introduced as the preeminent SLR camera with electronically controlled aperture-priority AE. Italian designer Giorgetto Giugiaro's design had a great impact on later cameras.

1980

1980

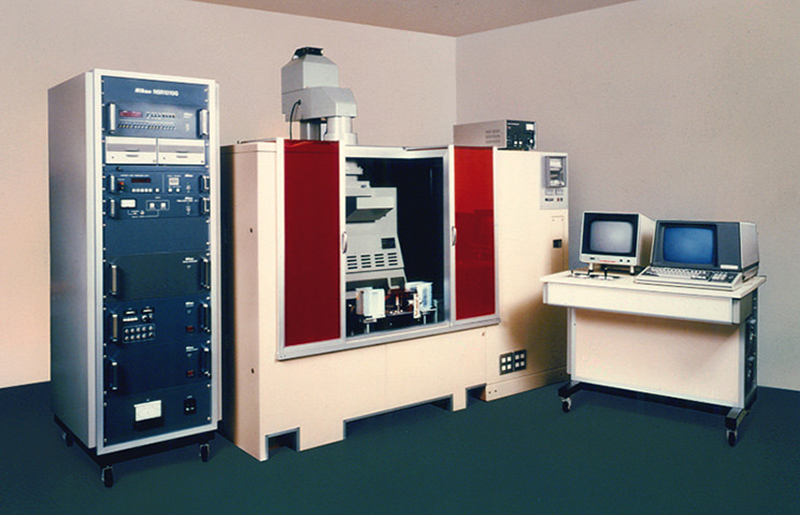

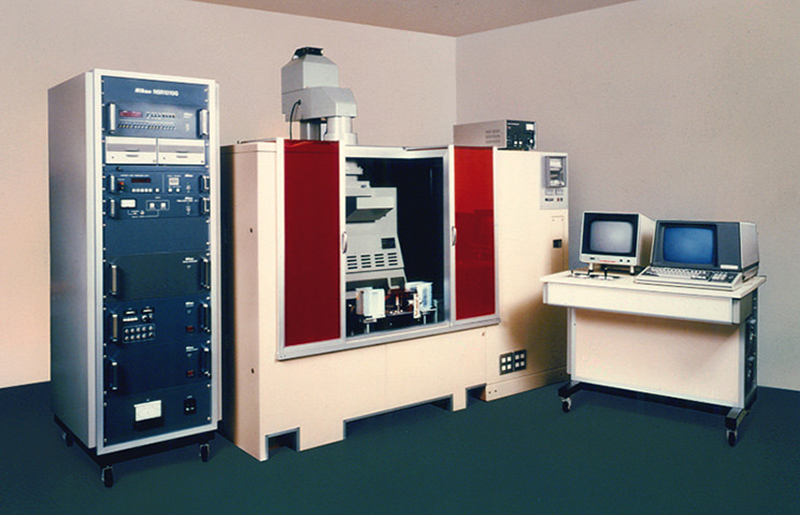

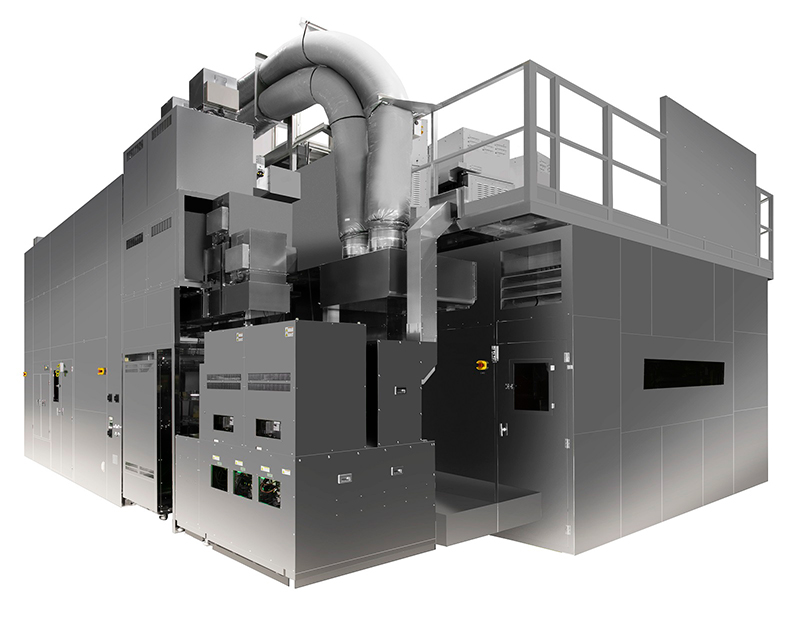

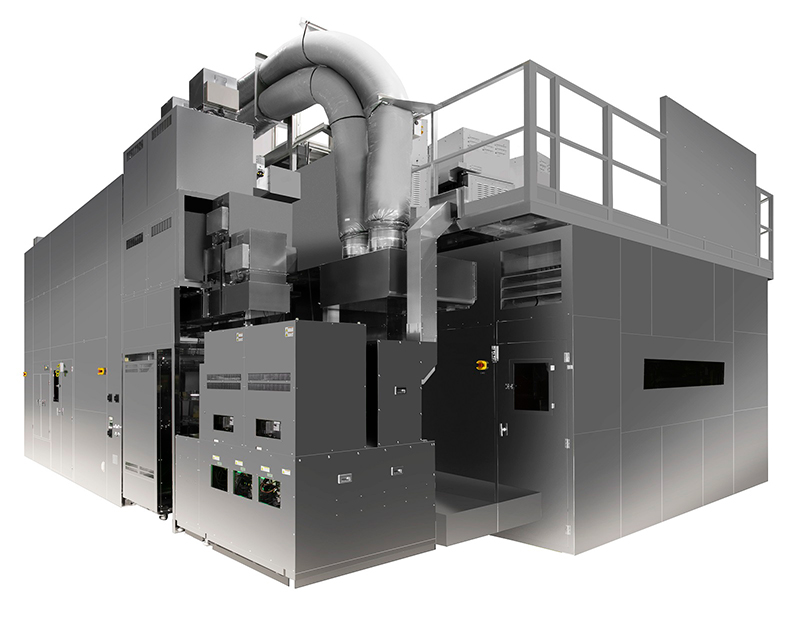

NSR-1010G Step-and-Repeat System (stepper) for manufacturing VLSIs is marketed

In 1976, the VLSI Technology Research Association (VLSI Labs) was promoted under the guidance of the Ministry of International Trade and Industry (currently The Ministry of Economics, Trade and Industry). The research association asked Nikon to develop a stepper to allow circuit pattern sizes to be reduced to one-tenth of what they were.

Key to this stepper would be a projection lens capable of high-precision resolution, and a high-precision, high-speed moving stage for positioning. The issue with an ultra-precise, high-speed stage is getting it to move straight. The device developed by Nikon was accurate enough to hit a tennis ball with an arrow on the top of Mt. Fuji all the way from Tokyo. Lastly, photo-electric sensors for converting light into electrical signals were needed. Nikon achieved all of these core technologies.

In March of 1978, the first prototype was delivered to the research association, followed by prototype 2. Both were highly acclaimed.

In February 1980, the NSR-1010G stepper was announced, the first domestically produced commercial device. This machine boasted one micrometer resolution and high overlay accuracy (alignment), and garnered a lot of attention for its promise in VLSI manufacture.

The first domestically manufactured commercial stepper. As a next-generation VLSI production device, it achieved a high level of integration, throughput and yield.

1981

1981

TITEX titanium ophthalmic frame is marketed

The world's first titanium ophthalmic frames. Stronger than conventional nickel alloy frames and some 50% lighter.

1981

1981

NASA-specification Nikon F3 is equipped on the Space Shuttle Columbia

In Autumn of 1978, NASA (National Aeronautics Space Administration) requested cameras to be made for the Space Shuttle.

NASA wanted a camera completed in a year and a half that could shoot 250 photographs with automatic exposure and whose film could be changed during shooting. Thus, in May of 1980, Nikon delivered the F3 Big Camera, a 250-shot device, and a 72-shot F3 Small Camera, which were based on the F3 under development at the time. In the following year, the F3 Small Camera was fitted to the Space Shuttle Columbia.

1981

1981

Nikon Fieldscope is marketed

1982

1982

OPTISTATION IC wafer inspection system is marketed

OPTISTATION is a device that enables automated wafer transport and efficient visual inspection. This was commercialized to replace the NICIS-MX2 wafer surface inspection apparatus released in 1979.

Used for visual inspection in the etch and lithography process of semiconductor manufacturing. It contributed to the stabilization of the production line and improved yields.

1983

1983

Nikon L35AF autofocus compact camera is marketed

Nikon's first compact camera.

1983

1983

Nikon F3AF SLR Camera is marketed

Based on the Nikon F3 body, signal contacts were included in the body to enable transmission and reception of viewfinder and AF lens signals via the body, and a drive motor was included within the lens.

The Nikon F3AF rose to the challenge of developing an AF mechanism

1983

1983

Alphaphot YS biological microscope series is marketed

The CF, a revolutionary optical system developed in 1976, was adopted for biological microscopes for practice use by interns, to expand its applications. With the adoption of CF optics with very little axial or magnification chromatic aberration, these microscopes were highest performance practice devices for medicine and dentistry students that enabled them to use accessories compliant with high-end equipment such as phase difference, epifluorescent and simple polarization equipment.

The Alphaphot YS expanded use of CF optical system to medical and dental students

1984

1984

NT-1000 35mm film direct telephoto transmitter is marketed

Nikon began looking into electronic imaging around the middle of 1979. In 1984, the company released the NT-1000 (B&W photographic), the world's first film direct telephoto transmitter jointly developed with Kyodo News Agency and designed for use by the press. This device revolutionized conventional systems to read enlarged prints and transmit them over telephone lines. The device could read photographic negatives and positives directly, and enabled trimming and simultaneous transmission of hand-written text while checking with a monitor to respond to the time-sensitive needs of the journalistic workplace. Also in 1988, the company released a still video camera system consisting of the QV-1000C electronic black and white camera, QV-Nikkor interchangeable lenses and the QV-1010T electronic transmitter. These technologies led to the development of Nikon's digital camera systems.

The world's first 35mm film direct transmitter. It was co-developed with Kyodo News.

1984

1984

NSR-1010i3 Step-and-Repeat System (stepper) is marketed

1985

1985

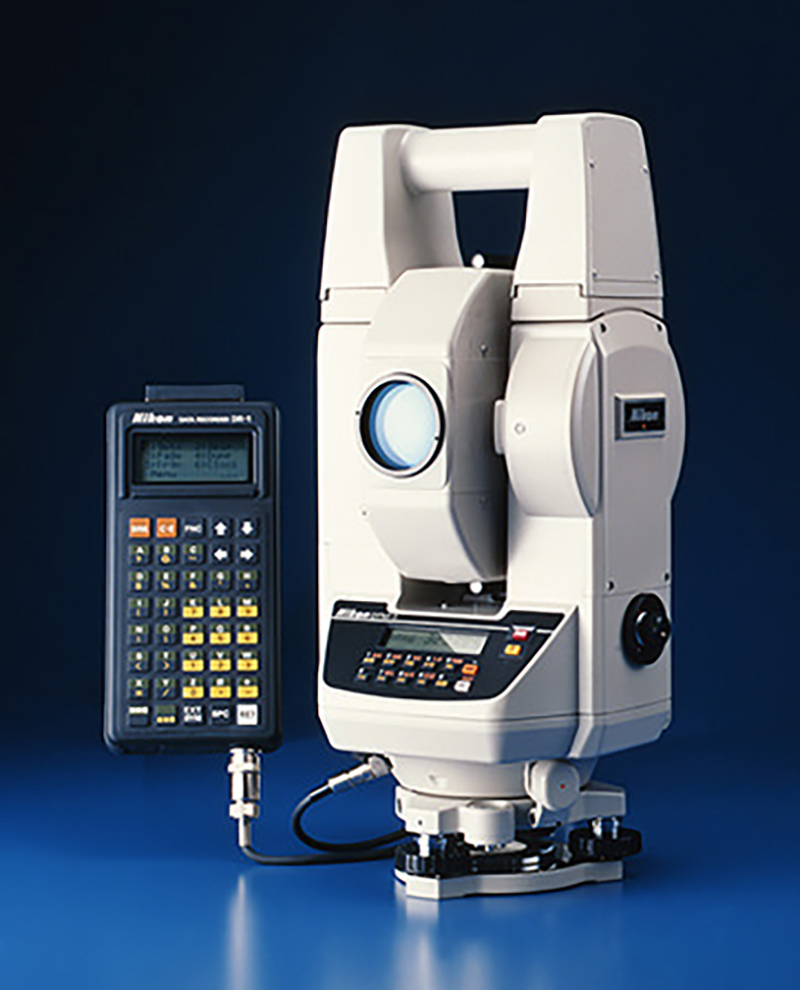

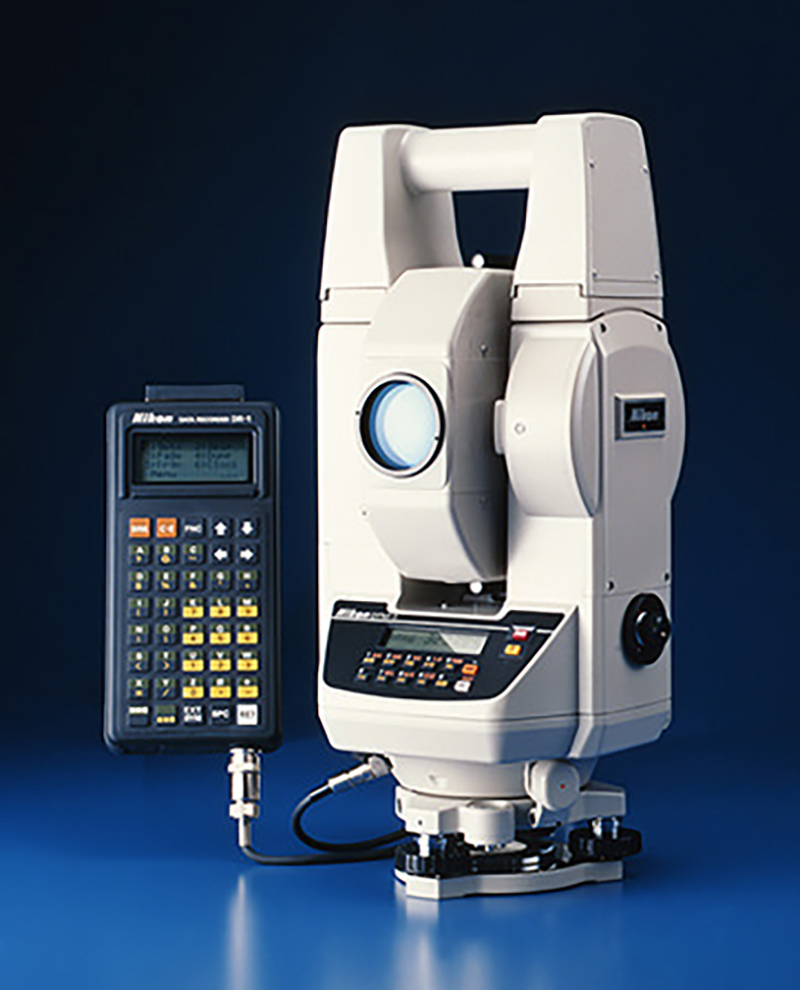

Total Station DTM-1 surveying instrument is marketed

The first Nikon Total Station and the first fully digitized Nikon surveying instruments.

1986

1986

TRISTATION 600 and 600M three-dimensional coordinate measuring machines are marketed

The first three-dimensional coordinate measuring machine designed by Nikon and the first such machine in Japan to achieve spatial measurement accuracy within five micrometers.

1986

1986

Nikon F-501 autofocus SLR camera is marketed

The first Nikon SLR camera with autofocus operated from the camera body.

1986

1986

NSR-L7501G large substrate exposure system is marketed

Making use of its semiconductor lithography technologies, Nikon engaged in the development of flat panel display (FPD) lithography systems for manufacturing LCD displays. Aiming for lithographs that could form 3-5 micrometer circuits (switches) on glass plates used for display substrates, the company released the NSR-L7501G large substrate exposure system in 1986. Semiconductor lithographs of the day were only capable of exposing a maximum area of 30mm square, but this equipment could expose 75mm square.

First of Nikon's LCD steppers and scanners. The launch was quick to meet the increasing demand for liquid crystal display products.

1988

1988

NSR-1505EX excimer stepper is marketed

1988

1988

Corporate name is changed to Nikon Corporation

On April 1, 1988 the Nippon Kogaku K.K. restarted as the Nikon Corporation. At the time, the Nikon brand already possessed an excellent reputation in a number of different fields. To spread globally, the company name was changed to develop as an international company, taking advantage of its name for reliability.

Both Nikon logotype and logo design format established at the time.

1988

1988

LS-3500 35mm film scanner is marketed

LS-3500 Color images taken on 35mm film are sent to a PC by converting them to digital signals.

1992

1992

Nikonos RS underwater AF SLR camera is marketed

The Nikonos RS enabled autofocus shooting underwater.

1995

1995

NEXIV series CNC video measuring system is marketed

Computer Numerical Control (CNC) image measurement systems use the image-processing technologies of computers and optical measurement technologies to measure and inspect the dimensions and shapes of workpieces, including precision devices and electronic components.

As electronic and automotive parts became more detailed and precise, the need for non-contact optical measurement systems to measure component surfaces without touching them was ever-more pressing. Furthermore, as automation in manufacturing became more prevalent, strong demand for automated, high-speed mass measurement industrial inspection processes emerged. To meet these demands, the company developed the Nikon EXcellent Intelligent Vision system (NEXIV) based on the concept of automating the vision and judgment of humans.

NEXIV uses a CCD camera to detect the edge of the workpiece from an image, and can process data to make complex measurements with high precision. The telecentric optics system does not change size even with focus shift or image blur (the size appears the same whether far or near). This is an appropriate optical system for processing and measuring images because the image dimensions are constant.

By developing this revolutionary technology, Nikon achieved detection with speed and accuracy beyond the capabilities of humans, which contributes to maintaining quality in inspection processes of cutting-edge precision parts as they become increasingly complex.

Non-contact high-precision measurement was made possible by image-processing technology. The confocal-type microscope enabled measurement of a two-dimensional field and height in the same field of view.

1995

1995

E2 and E2s digital still cameras are marketed

Developed with Fuji Photo Film Co., Ltd. (now FUJIFILM Corp.), these SLR-type digital cameras are equipped with the unique Reduction Optics System and are compatible with major F-mount lenses.

1995

1995

NSR-S201A lens-scanning KrF excimer stepper is marketed

The world's first lens scanning type KrF excimer stepper (KrF scanner) corresponding to design rules of less than 0.25 micrometers.

1996

1996

Nikon Fieldmicroscope is marketed

A portable stereoscopic microscope that allows "as is" observation.

1996

1996

ECLIPSE E800 biological microscope for research is marketed

The optical system of the infinity optics (CFI 60) system was revamped to make the parfocal distance of the objective lens 60mm.

1997

1997

COOLPIX 100 and 300 digital cameras are marketed

Nikon's first compact digital camera. The COOLPIX 100 shown here could be inserted into a PC card slot to transfer data directly to the computer. Pen-touch operation was possible with the COOLPIX 300.

1999

1999

Total Station GF-212 and 215C surveying instruments featuring non-prism measuring method are marketed

Features a non-prism measuring function that enables measurement without a reflective prism by using a laser beam.

1999

1999

D1 digital SLR camera is marketed

Based on the concepts of "superb image quality" "ultra-high speed" and "ease of use," the Nikon D1 was a lens-interchangeable AF digital SLR camera that was revolutionary in various aspects such as image quality, speed, dimensions, weight and price.

This project was launched in 1996 directly under the president, and was intended to develop a new and genuine digital camera product within two years. The challenge was taken up by about 10 people from design and other divisions. Initially, team leaders asked for three years on the grounds that two years was insufficient since the company did not possess much accumulated digital technology at that time. However, the response was "Nikon does not have that much time right now" and the company endeavored to make it happen in just two short years. In 1998 Nikon released the COOLPIX 900 compact digital camera and the professional D1 digital SLR camera in September the following year. This was a ground-breaking device that offered the comprehensive strengths of excellent image quality, operability and functionality while being only about a third of the price of competitor's products, at JPY 650,000, thereby spurring on the popularization of digital SLR cameras. Since then, Nikon has continued to produce advanced flagship models exceeding professional expectations, right up to the new D5 Nikon digital SLR camera.

SLR-type digital camera with interchangeable lens that combines high-speed performance and overall picture quality. Priced with general users in mind, it contributed to the popularity of digital SLR cameras.

2000

2000

FX-21S LCD scanner is marketed

The FX-21S is an LCD lithography system that exposes circuit patterns on the mask using multiple projection lenses on the glass plate by scanning and step-and-repeated exposure.

At the time, desktop PC monitors were beginning to adopt the Thin Film Transistor (TFT) active matrix color LCDs created for laptop displays. However, there was an opportunity for an even bigger market. While development progressed with an eye on LCD panels for large-size TVs, these technologies could be adopted for 15-inch glass panels for TV monitors.

FX-21S did not employ the common stepper method at that time (step and repeat exposure) for exposure and image transfer, but instead used a 5-projection lens optical system capable of exposing a 30-inch wide display in a single scan, with dramatically increased throughput.

Nikon's original multi-lens system was adopted to correspond to an increase in the size of liquid crystal displays.

2000

2000

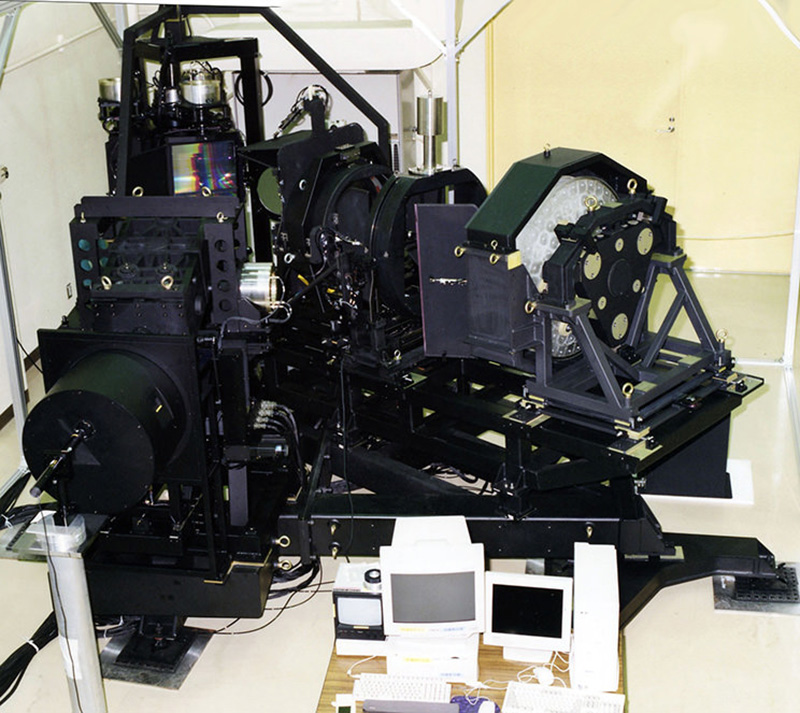

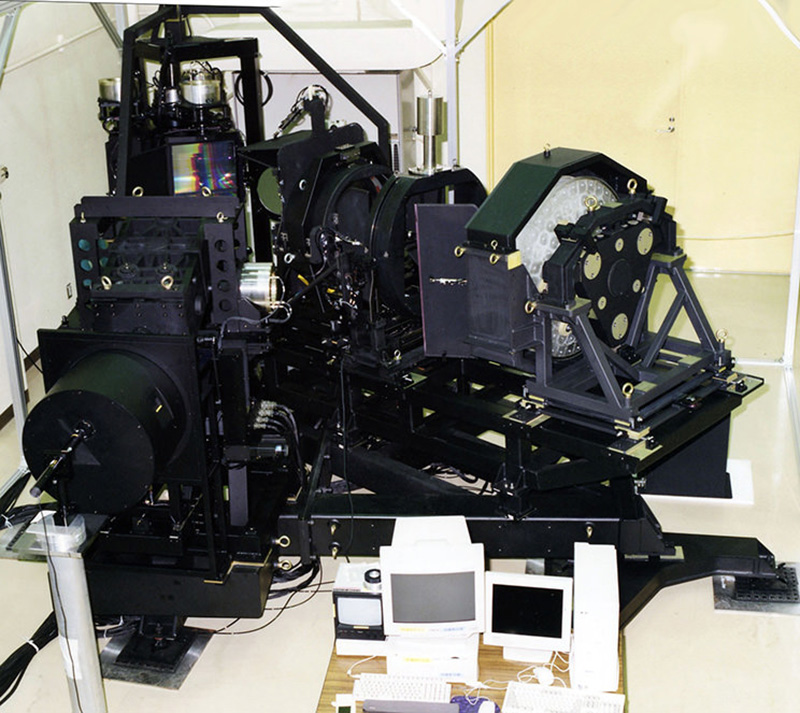

Optical-infrared Subaru Telescope employs Nikon's High Dispersion Spectrograph (HDS) and Faint Object Camera And Spectrograph (FOCAS)

Mauna Kea, Hawaii rises at 4,205 meters above sea level. As one of the peaks of the world suitable for astronomical observation, numerous countries have brought many telescopes to this location. One of these is the Subaru Telescope, which features the High Dispersion Spectrograph (HDS) and Faint Object Camera And Spectrograph (FOCAS) devices, developments in which Nikon was involved. Research with optical telescopes usually involves three technologies — observation equipment to take photographs, high-dispersion spectrometer equipment, and high-sensitivity low-dispersion spectrometers. With the Subaru Telescope, these consist of the primary focus camera, high-dispersion spectrometer (HDS), and low-dispersion spectrometer (FOCAS).

HDS is a spectroscope that sorts the spectrum of light arriving from distant celestial objects. High-dispersion spectrography of celestial objects plays a role in clarifying the historical origins of various elements by investigating the elemental composition of ancient stars formed around the time of the beginning of the universe. Nikon was responsible for production of the FOCAS body and its main lenses, a device with the power to discover distant galaxies seemingly at the end of the universe.

FOCAS made its first observations in February of 2000. Not only has this device been employed to discover galaxies 12.8 billion light years distant, but also staked its claim with nine of the ten furthest deep space objects announced in 2006 having been found by the Subaru Telescope's prime focus camera.

Announced in April of 2005, HDS has discovered stars with the lowest iron composition in the history of observation, and has been successful in measuring elemental compositions. These bodies have only 1/250,000th of the iron composition of the sun. This has led to high anticipation of shedding more light on the initial elemental composition of the early universe.

FOCAS is installed on the Subaru Telescope.

© National Astronomical Observatory of Japan

© National Astronomical Observatory of Japan

© National Astronomical Observatory of Japan

© National Astronomical Observatory of Japan

© National Astronomical Observatory of Japan

2001

2001

NSR-S306C lens-scanning ArF excimer stepper is announced

Lens scanning type ArF excimer stepper (ArF scanner) supports mass production of 100-nanometer devices.

2003

2003

Brand Symbol for Nikon Group is introduced

This brand symbol was established under the concept of "fusing the future possibilities with reliability." The symbol of "sequential rays" represents the future possibilities, while preserving the black Nikon logo-type that has gained worldwide recognition and yellow brand color. Nikon intends to accurately recognize the needs of the times and fully meet the expectations of its customers. The Nikon brand symbol expresses the aspiration of the company to be unrelenting in facing the challenges of technical innovation and keeping the passion alive to turn today's dreams into tomorrow's new realities.

The brand symbol displaying the light motif.

2004

2004

Nikon F6 SLR camera is marketed

Introduced as the preeminent film SLR camera, it combined Nikon F series tradition with advanced features.

2006

2006

NSR-S609B ArF immersion scanner is marketed

The NSR-S609B ArF immersion scanner is a system that exposes silicon wafers with circuit patterns used in LSI manufacturing, and is a revolutionary product proposed to the industry by Nikon ahead of other companies. It radically changed the direction of immersion lithography technology. By filling the gap between the projection lens and the wafer with purified water, the device broke through the N.A.* 1.0 barrier, previously insurmountable with conventional dry exposure, achieving the world's highest N.A. of 1.07.

The ever-increasing integration of VLSI, a core technology of the IT revolution, means the width of IC circuit lines is required to be narrower. However, IC manufacturing methods that use light to print circuits are limited by a theoretical boundary due to the refractive index of air, beyond which further narrowing is not possible. Thus, liquid immersion exposure technologies with purified water (refractive index 1.44), which has a higher refractive index than air (refractive index of 1) between the semiconductor lithograph lens and the wafer, achieve higher precision by utilizing the liquid itself like a lens. This technology has enabled the manufacture of ICs at the 55-nanometer level or smaller, a major breakthrough beyond the conventional limitation (a nanometer is a millionth of a millimeter). Moreover, liquid immersion exposure technology can be implemented without major changes to the principles or structure of conventional semiconductor lithography equipment, hence enabling swift response to demand along with IC advances.

*N.A. is a performance index for numerical aperture.

The first IC Stepper and Scanner model incorporating Immersion Lithography Technology and the first to break the barrier of N.A. 1.0 in air to achieve N.A. 1.07.

2007

2007

BioStation CT cell culture observation system is marketed

In the field of biosciences, particularly in regenerative medicine and drug manufacture, the use of live cells in research and industry is expected to become more active. Live cells are usually carefully raised in an incubator with a temperature maintained at 37°C, the same as the human body, with humidity at 95% and CO2 concentration of 5%. "BioStation CT" (cell tracking) is a cell culture observation system that makes it easy to grow cells safely and stably, and control the quality of cells. In the past, cells had to be taken out of the incubator to observe them with a microscope, which although requiring only a short amount of time could result in problems such as reduced cell activity or mold infestation.

BioStation CT is a groundbreaking device that turns convention on its head by including a microscope inside the incubator so that the growth of live cells can be observed without removing them. Since this means growing large amounts of cells with quality control, BioStation CT can also be considered a device enabling laboratory automation for the first time. Although adopted experimentally, it has already been employed in iPS and cancer cell research, producing promising results.

Equipped with a microscope in the incubator, it has expanded the possibilities of live cell observation.

2009

2009

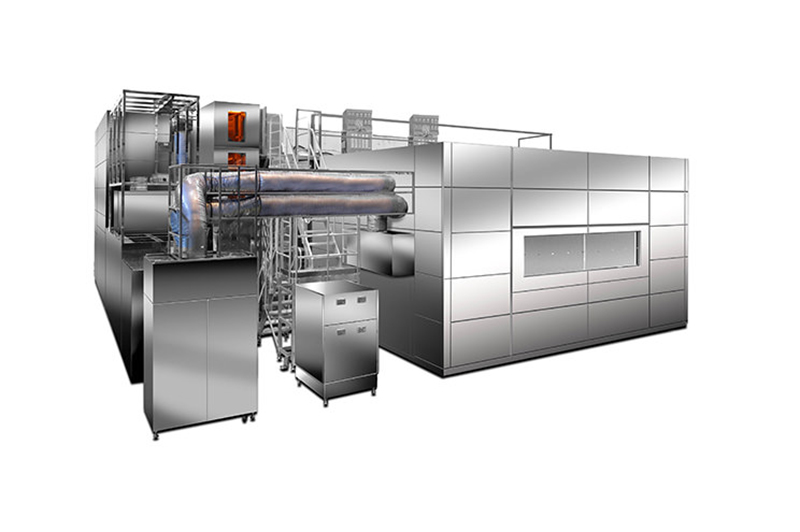

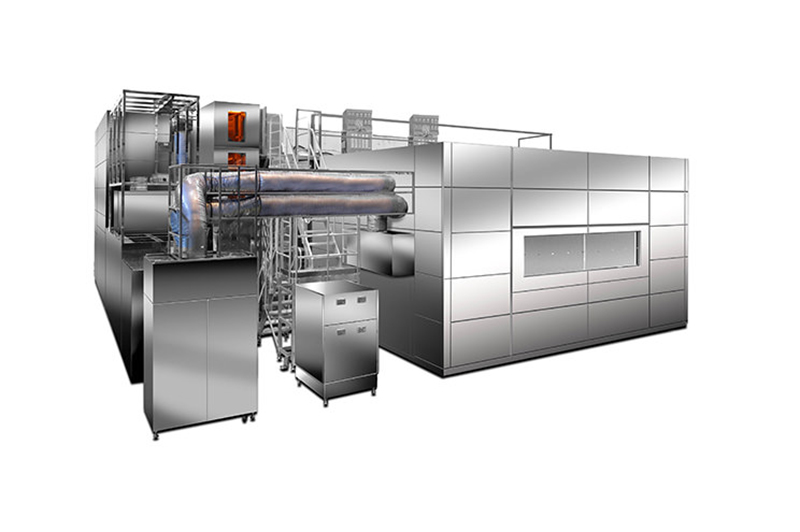

FX-101S LCD scanner is marketed

In recent years, LCDs are increasingly becoming larger with higher definition. The pixel count of HiVision LCD TVs is higher than 2 million, and the number of switches exceeds 6 million with the red, green and blue elements that make up each pixel (2 million x 3 colors). An LCD scanner (FPD lithography system) is used to print the circuits to create these tiny switches on the thin glass plate of the LCD monitor; switches so small they are invisible to the naked eye.

To manufacture LCDs more efficiently, there is demand to print circuits on even larger areas simultaneously, and produce many display panels from a single glass plate. Nikon responded to the demands for large-size glass plates with a multi-lens array. This enables wide area printing by precisely aligning many projection lenses and entails a self-calibration system that seamlessly joins the exposure patterns of each lens so that large areas can be exposed with precision at the same time.

The FX-101S handles the world-first 3m x 3m device Gen 10 plate size and propels the rapid spread of large-size TVs, laptop computers, and LCD monitors. Nikon's FPD lithography system is major technology driving the information society.

Supporting Gen 10 mother glass (about 3 meters square), the FX-101S enables effective mass-production of large panels of over 60 inches.

2009

2009

NSR-S620 ArF immersion scanner is marketed

Corresponds to a production process using double patterning.

2009

2009

Metris NV becomes Nikon Metrology NV, a wholly owned subsidiary of Nikon Corporation in Belgium

2010

2010

D3S and D3X digital SLR cameras, and NIKKOR lenses are used in the International Space Station (ISS)

In 2009, Nikon delivered eleven D3S digital SLR cameras and seven AF-S NIKKOR 14-24mm f2.8G ED interchangeable lenses to NASA (National Aeronautics Space Administration) for recording images in the International Space Station (ISS). Then in 2010, Nikon delivered one D3S and two D3X cameras along with various interchangeable lenses such as the AF-S NIKKOR 400mm f/2.8G ED VR, accessories and software to the S. P. Korolev Rocket and Space Corporation Energia, a company commissioned by the S.P. Russian Federation Space Agency for recording images in space. All these devices are in use for both internal and extravehicular activities for both the US and Russian sections of the ISS.

2010

2010

N-SIM and N-STORM super resolution microscopes are marketed

For advanced research in the life sciences, optical microscopes are essential, universally sought-after instruments for observing living cells and tissue in detail. However, to view objects 200 nanometers or smaller, such as protein molecules which are too small to be seen with the resolution of conventional optical microscopes, electron microscopes were used. Two ultra-high resolution microscopes achieve resolution that far surpasses that of the conventional optical microscope, realizing observation of the detailed structure of living cells down to the molecular level.

N-SIM employs technology called structured illumination microscopy. This revolutionary technology uses striped illumination and converts the moiré fringes that result into image data of the micro structure to reproduce detailed structural shapes through spatial frequency analysis, and achieves a resolution (115 nanometers) about twice that of conventional optical microscopy. Thus, this enables more detailed observation of living tissue and cells.

N-STORM probabilistic rebuild optical microscopy. This system reconstructs high-resolution fluorescent images by combining position information of individually dyed molecules detected with high precision from multiple fluorescent images. It attains ultra-high resolution roughly 10 times that of optical microscopy, enabling intracellular observation that is a step further toward the molecular level.

Ultra-high resolution microscopy technologies provide even greater support to cutting-edge research in universities as well as biological, medical and healthcare institutions.

Achieved a resolution that is beyond the capabilities of conventional optical microscopes. The photo shows the "N-SIM", which has nearly double the resolution of conventional optical microscopes.

2010

2010

HN-6060 non-contact multi-sensor 3D metrology system is marketed

High-accuracy measurement is indispensable in order for advanced processing technologies to attain the extremely strict levels of precision demanded in the precision machining workplace. Conventionally, contact-type measuring equipment was used to inspect machined parts, however this method does not lend itself to quick turnaround, and shortening the time for measurement and reducing measurement points can lead to incomplete evaluation.

Instead, employing lasers to illuminate workpieces to acquire data from many points enables measurement with non-contact 3D measurement. Previously, non-contact 3D measurement equipment was not commercialized in the high-precision field because its accuracy ranged only from several hundred to several tens of micrometers, while the field required higher levels of precision.

The HN-6060 is a non-contact multi-sensor 3D metrology system developed by Nikon that utilizes light-cutting sensors to provide non-contact measurement with a level of precision on a par with contact measurement. Also, with high-speed digital measurement data conversion, the system achieves high efficiency with 120,000 data items acquired per second.

Whereas items such as gears once required a lot of time to measure, this high-speed, high-precision system correctly assesses the form, from gear teeth tips through to gear valleys, in just a few minutes.

An object's shape and waviness can be measured in a single operation, a difficult achievement for conventional measuring instruments.

2011

2011

Nikon 1 J1 and V1 advanced cameras with interchangeable lenses are marketed

Nikon's first advanced cameras with interchangeable lenses. Video and still images are of equally high quality. The photo shows the Nikon 1 J1.

2012

2012

D4 digital SLR camera is marketed

The flagship model of Nikon digital SLR cameras, it achieves high sensitivity and high image quality as well as excellent high-speed performance. Reflecting the real needs of photographers in the field, operability and reliability have been pushed to the limits.

2013

2013

SPRINT-A HISAKI—the Spectroscopic Planet Observatory for Recognition of Interaction of Atmosphere is equipped with a primary mirror developed by Nikon

On the 14th of September 2013, the Japan Aerospace Exploration Agency (JAXA) successfully launched its Epsilon rocket, equipped with the Spectroscopic Planet Observatory for Recognition of Interaction of Atmosphere (SPRINT-A), from the Uchinoura Space Center in Kagoshima Prefecture. After that, SPRINT-A was injected safely into the orbit and renamed HISAKI. HISAKI is the world's first space telescope dedicated for remote observation of planets such as Venus, Mars and Jupiter, and orbits the earth at an altitude of about 1,000km. Nikon contributed to this project by producing the primary mirror for the telescope (diameter 20cm). This mirror is made of silicon carbide (SiC), a material that is extremely hard and difficult to work, but was successfully completed making full use of the company's high-precision processing technology.

Nikon has also contributed to the development of many satellites and space probes including the land observing satellite DAICHI launched in January 2006, the infrared astronomical satellite AKARI launched in February 2006, and the Venus climate orbiter AKATSUKI launched in May 2010. Nikon will continue to provide support to projects by taking up the challenge of space observation and measurement with its high-precision optical design and processing technologies.

2015

2015

Compact Digital Camera COOLPIX P900 is marketed

The COOLPIX P900 provides an 83x optical zoom lens offering coverage from 24mm wide-angle to 2000mm telephoto (35mm equivalent). The fast maximum aperture lens, equipped with Super ED (Extra-low Dispersion) lens element offering superior compensation for chromatic aberrations, delivers superior results with vivid images, even when zoomed to extreme levels.

2015

2015

U.K.'s Optos Plc becomes a wholly owned subsidiary of Nikon Corporation

2015

2015

The Nikon Museum is opened

Established for the 100th anniversary of Nikon's foundation in 2017.

2016

2016

NSR-S631E ArF immersion scanner is marketed

ArF immersion scanner developed for mass production of 7-nanometer node process semiconductors (supporting multiple patterning).

2016

2016

FX-68S FPD Lithography System is marketed

Gen 6 Plate FPD Lithography System that has achieved to deliver a high resolution of 1.5 micrometers.

2016

2016

D5 digital SLR camera is marketed

The flagship model with innovative features such as the refined acquisition of subjects in motion and an expanded sensitivity range, that is responsive to a wide variety of scenes and subjects.

2016

2016

Achieved a total production of 100 million NIKKOR lenses for interchangeable lens cameras

2016

2016

Nikon's first action cameras KeyMission 360, KeyMission 170, and KeyMission 80 are announced

-

KeyMission 360

-

KeyMission 170

-

KeyMission 80

Nikon's first action camera KeyMission Series featuring water- and impact-resistance to withstand harsh environments and Nikon's world-class optical and image-processing technologies to satisfy the high expectations of adventurers who challenge the limits.

2016

2016

U.K.'s Mark Roberts Motion Control Limited becomes a wholly owned subsidiary

2017–

Shape the future

With Light, Towards the Next 100 Years

Nikon has walked alongside everyday

life and human challenges while

innovating a wide spectrum of optical

equipment throughout the years.

With effective solutions generated

from technologies and ideas,

we will continue to advance

over the next 100 years.

2017

2017

WX series binoculars are marketed

Feature a super-wide field of view while assuring a sharp and clear image across the entire field of view. These binoculars are a new series of high-performance models and ideal for astronomical observation. The image shows WX 7x50 IF binoculars.

2017

2017

Nikon celebrates its 100th anniversary

As part of Nikon's 100th anniversary projects, we developed a 100th anniversary logo. We also released 100th anniversary products and held events/campaigns all over the world.

2017

2017

D850 digital SLR camera is marketed

The D850 has an effective pixel count of 45.7 megapixels, and continuous shooting speeds of up to approximately 9 fps. It supports full-frame 4K UHD (3840x2160) movie recording to expand possibilities for imaging expressions.

2018

2018

FPD Lithography Systems FX-103SH and FX-103S are marketed

Support the Gen 10.5 plate size. The FX-103SH and FX-103S are FPD lithography systems optimized for the mass production of 4K and 8K TVs, LCD panels for high-definition tablets and organic light emitting diode (OLED) panels.

2018

2018

FX-format mirrorless camera Z 7 is marketed

The Z 7 is the first FX-format mirrorless camera employing the newly developed Nikon Z mount system.

The development of the Z mount system started with a simple idea:to capture space as it really is. Based on the diverse array of knowledge accumulated during the 59-year history of the F mount, optical design that can transmit light to an image sensor in its purest form was pursued. This resulted in the creation of a new mount featuring a 55-mm inner diameter and 16-mm flange focal distance. As the core of the Z mount system, it provides tremendous possibilities for raising optical performance to a different dimension. With the greatly enhanced flexibility of lens design, advanced lenses that deliver outstanding performance in brightness, resolution and focus accuracy can be created, while unique lenses such as an extremely fast lens, a lens offering an unprecedented focal length, and a lens with individual rendering characteristics have also been made possible.

Adopting a backside illumination CMOS sensor with focal-plane phase-detection AF pixels, the Z 7 provides 45.7 effective megapixels while supporting a standard sensitivity range of ISO 64 to 25600. The 493 focus points enable broad coverage of approximately 90% of the imaging area both horizontally and vertically. An electronic viewfinder that utilizes superior optical and image-processing technologies achieves a clear and natural view. The compact and light body realized by a mirrorless camera ensures secure shooting with an easy-to-hold grip while also providing superb durability.

The newly developed Z mount system is adopted. With 45.7 effective megapixels, this high-pixel-count model can fully exploit the real value of NIKKOR Z lenses.

2019

2019

Lasermeister 100A optical processing machine is marketed

Based on the concept of becoming a "metal processing machine that can be handled by anybody", the optical processing machine Lasermeister 100A was developed with the goal of creating a brand-new market and industry in the world of monodzukuri (manufacturing).

The advanced optical technology and precision control technology that Nikon has long developed through manufacturing its semiconductor lithography systems known to be the "most precise machinery in history" enabled realization of a high-quality, smaller sized and less expensive processing machine.

This optical processing machine is a Nikon's proprietary metal processing machine that performs various metal processing with ease and high precision using laser. Its capability encompasses additive manufacturing as a 3D printer, laser marking and welding, along with even polishing.

2019

2019

The Nikon BioImaging Lab supporting drug discovery research is established in Boston

2020

2020

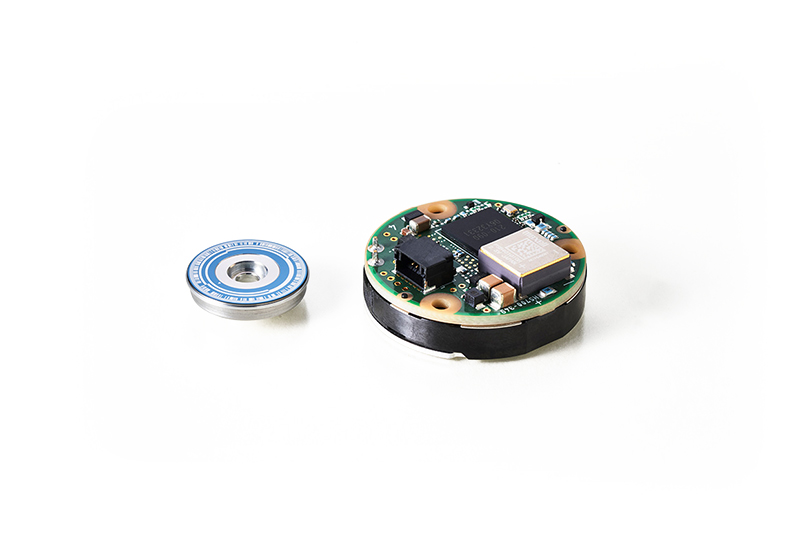

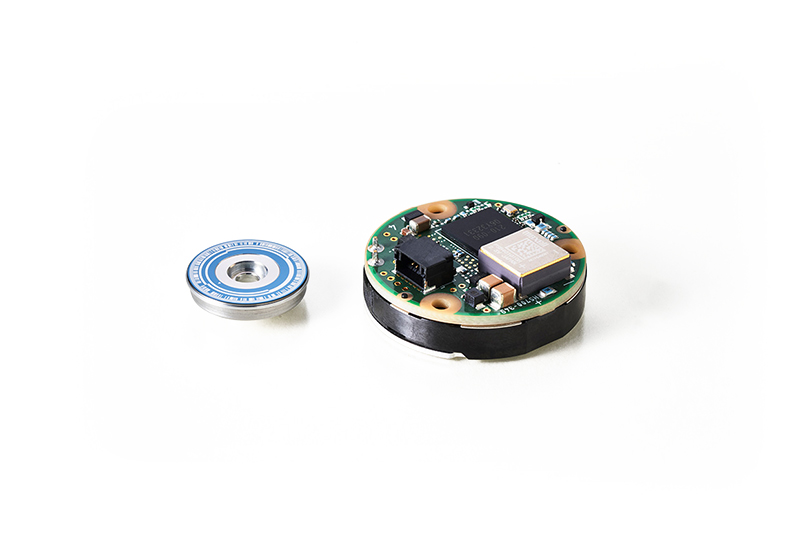

C3 eMotion, intelligent actuator unit for robotic joints of collaborative robot is marketed

The C3 eMotion operates under Nikon's proprietary double-encoder arrangement (containing two encoders), which enables detection of external forces and robot operation stoppage in response, direct teaching in which the robot can learn commands via direct manipulation by human users, and a wide range of other useful functions.

In the next generation, expectations for robots are rising, such as their function as future workers in production facilities, operating alongside human workers to cooperatively complete tasks. However, sophisticated skills and know-how are required to build robots, as they comprise a wide array of components.

The C3 eMotion realized more flexible and easier robot design based on the concept of "connect, control, cooperate".

The C3 eMotion is a robotic joint unit in which Nikon combines motors, speed reducers, motor drivers and brakes, as well as the encoders that have been one of Nikon's strength for a long time, in a single package. Utilizing multiple intelligent actuator units together facilitates easier building of robots by manufacturers as well as a wide range of other engineers — even those without know-how in robot design.

2020

2020

D6 digital SLR camera is marketed

The FX-format digital SLR flagship model that meets the needs of professional sport photographers and photojournalists with the most powerful AF performance in Nikon's history, high-speed continuous shooting and fast image transfer.

2020

2020

10x25 STABILIZED binoculars are marketed

Featuring a foldable lightweight and compact body with excellent portability, these are the first Nikon compact binoculars to employ the STABILIZED function.

2020

2020

ECLIPSE Ei educational microscope is marketed

An educational microscope designed for intuitive operation with video tutorials. Combined with a microscope camera and imaging software, it enables users to share microscopic images, in answer to demands for new communication tools optimized for online/remote educational use.

2020

2020

APDIS series large-volume non-contact measuring system is marketed

Employing Nikon's unique laser utilization technology, it is possible to acquire three-dimensional coordinates of large objects such as automobiles and aircraft via non-contact measurement, with an accuracy of tens of micrometers.

This compact, portable measuring system can be installed on robot arms, so that components can be inspected on automobile production lines rather than bringing them to an inspection room, contributing to improved productivity at manufacturing plants.

2021

2021

Acquired majority ownership of Morf3D Inc. (now, Nikon AM Synergy Inc.), an aerospace component manufacturing company in the U.S.A.

2021

2021

Lasermeister 102A optical processing machine is marketed

An optical processing machine capable of additive manufacturing with titanium alloy.

Compared to the conventional product, the Lasermeister 101A, the modeling speed has approximately doubled.

2021

2021

AX and AX R confocal microscopes are marketed

Confocal microscope systems that can capture high-resolution 8K x 8K images with a 25-mm field of view. Minimizing photobleaching and phototoxicity, while realizing intuitive operation via NIS-Elements C imaging software, these models expand the possibilities for research in various fields, such as elucidation of the mechanisms of cranial nerves and cancer, stem cells, and drug discovery.

2021

2021

Golfer's Laser Rangefinder COOLSHOT series is renewed

Instantly measures the distance to the target with an infrared laser. The lineup has been expanded to four products, the COOLSHOT PRO II STABILIZED, COOLSHOT LITE STABILIZED, COOLSHOT 50i and COOLSHOT 20i G II, enabling selection according to the purpose and application.

2021

2021

Mirrorless camera Z fc is marketed

This mirrorless camera further enhances the joy of shooting and ownership with a heritage design inspired by an iconic Nikon camera. While providing high performance and superb operability, it features a highly portable and lightweight body.

2021

2021

Lasermeister 1000SE and Lasermeister 1000S optical processing machines are marketed

Employing an ultra-short pulse laser and built-in non-contact 3D measurement, these machines perform high-precision subtractive processing with ease for a wide variety of materials.

By automatically creating the processing path based on CAD data, they help drive digital transformation through consolidating processes on the production line and simplifying quality control.

2021

2021

FX-6AS FPD Lithography System is marketed

The optimal FPD lithography system for manufacturing both high-definition organic light emitting diode (OLED) panels and LCD panels for the latest and high-definition mobile devices. With its newly developed projection lens, the FX-6AS realizes the highest level of resolution, high alignment accuracy, and high throughput, supporting the evolution of smart devices.

2021

2021

FX-format mirrorless camera Z 9 is marketed

The Z 9 was developed with the concept of "proposing how Nikon's flagship mirrorless camera should be".

Eliminating the display delay of the electronic viewfinder that has been taken for granted in mirrorless cameras until now, and featuring a Real-Live Viewfinder that provides constant visibility over the course of the whole shot, the Z 9 completely eradicates stressful blackout. It made it possible to capture decisive moments that were difficult to capture before.

AF speed has evolved into another dimension of immediacy and accuracy with the combined power of the high-speed readout of the stacked CMOS sensor featuring 45.7 effective megapixels, and the EXPEED 7 image-processing engine that dramatically improves processing power.

Subject detection performance has also evolved dramatically. It automatically detects nine types of subjects, including people, animals, birds, and vehicles. Photographers can now concentrate fully on the composition and shutter timing of key moments that were previously difficult to capture.

While employing various innovative functions, when it comes to design, Nikon is dedicated to pursuing a close understanding of the way photographers think.

The Z 9 was designed so that the area touching the palm when gripped is increased, to reduce the feeling of weight and physical load. To that end, we asked many staff members and professional photographers to handle the camera. We were attentively listening to the voices of actual users and repeating shape adjustments right up until the deadline for mass production.

The first flagship model of the Z series mirrorless cameras, bringing together Nikon's leading-edge technologies to deliver the best still and video features and performance in Nikon history.

2022

2022

NIKKOR Z 400mm f/2.8 TC VR S, a fast, super-telephoto prime lens is marketed

The first NIKKOR Z super-telephoto prime lens belongs to the S-Line of NIKKOR Z lenses, which pursue the ultimate in optical performance. It features a built-in teleconverter that extends the focal length by 1.4x, allowing the lens to cover two focal lengths — 400 mm and 560 mm.

The newly developed Meso Amorphous Coat boasts the highest anti-reflection performance in NIKKOR history, handling incident light from various directions effectively. Further, it adopts the newly developed Silky Swift VCM (SSVCM) for its AF drive, realizing fast, highly accurate and quiet AF control.

2022

2022

NIKKOR Z 800mm f/6.3 VR S super-telephoto prime lens is marketed

Employing a PF (Phase Fresnel) lens for the first time in the NIKKOR Z lineup, it achieves reduction of both weight and length. With the lens' center of gravity positioned closer to the body side, users are less aware of the weight of the lens even if it is swung around during panning.

2022

2022

Ultra-compact machine vision camera LuFact is marketed

In order to automate the monitoring and visual inspection of manufacturing processes that were previously performed by humans, a machine vision camera that can quickly capture images with ultra-fine sensitivity and resolution, and that is also compact and lightweight with a high degree of freedom in installation, is essential.

The LuFact captures images with superior sensitivity and resolution, while achieving an ultra-compact design by separating the I/F conversion unit that performs image processing. It improves operations and enhances efficiency to support digital transformation at manufacturing sites.

Nikon's first machine vision camera leveraging its specialized image-processing technology that has been developed across many years of digital camera innovation.

2022

2022

NIKKOR Z 600mm f/4 TC VR S super-telephoto prime lens is marketed

A super-telephoto prime lens that is one of the S-Line of NIKKOR Z lenses, pursuing the ultimate in optical performance. It features a built-in teleconverter that extends the focal length by 1.4x, enabling coverage of two focal lengths — 600 mm and 840 mm.

2023

2023

Established Nikon Advanced Manufacturing Inc., the company overseeing the additive manufacturing business, in the U.S.A.

2023

2023

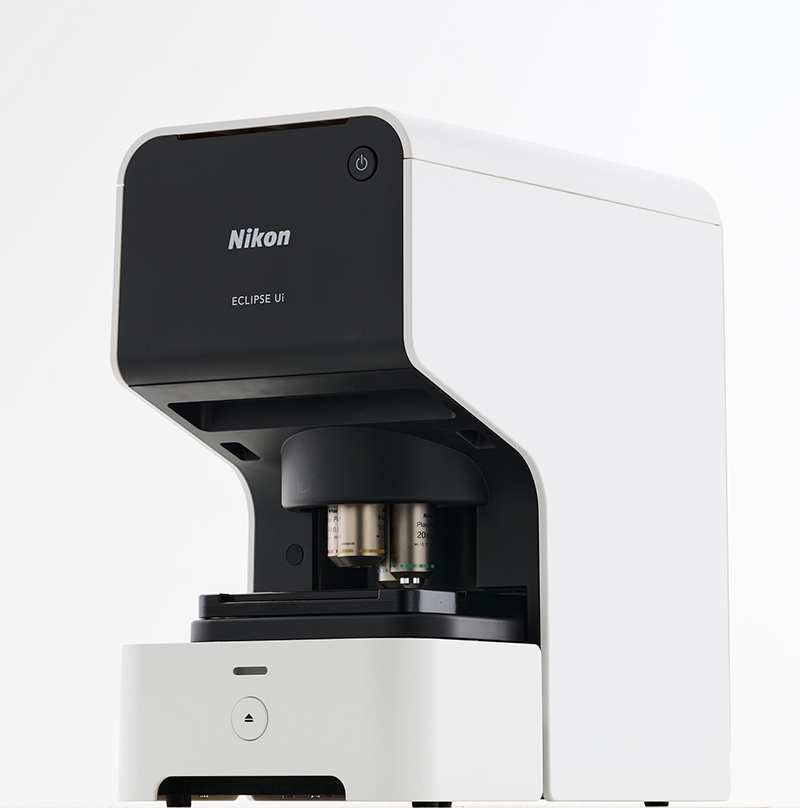

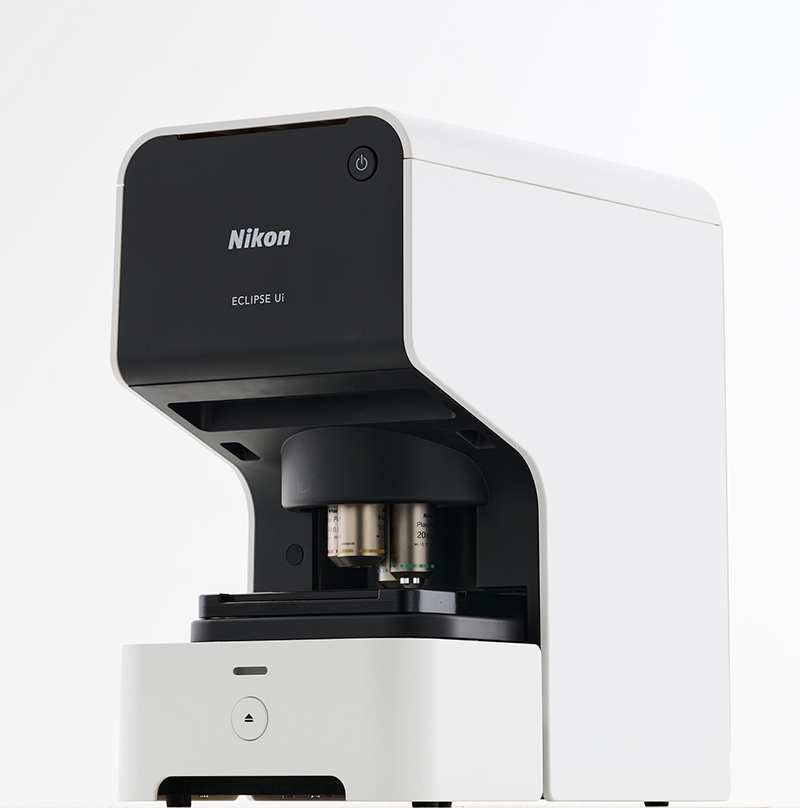

ECLIPSE Ui*1 digital imaging microscope for medical use is marketed

The first-ever microscope for medical use in Japan*2. As a microscope, it features a unique design without an eyepiece lens.

- *1Proprietary name: Digital Imaging Microscope Ui

Medical device notification number:

[After]13B2X10606000001(After September 13, 2024. Due to relocation of a manufacturer)

[Before]14B2X10066000001 - *2As an optical microscope for displaying digital images (JMDN: デジタル画像表示光学顕微鏡) that has been notified as a medical device as of April 12, 2023 (surveyed by Nikon)

2023

2023

VOXLS 40 C 450 large-volume X-ray and CT Systems are marketed

The VOXLS 40 C 450 realizes non-destructive inspection of various components, from small to large by using the X-ray and CT (computed tomography scan) function to implement high-accuracy measurement, confirmation of internal shapes, and defect analysis.

2023

2023

FX-format mirrorless camera Z 8 is marketed

The Z 8 condenses the advanced functionality and performance of the flagship Nikon Z 9 into a compact and lightweight body while also maintaining superior robustness and reliability. It is ideal for a variety of image creators who seek new possibilities for visual expression in a wide range of genres and subjects.

2023

2023

Forestry Pro II J Laser Rangefinder for forestry/commercial use is marketed (in Japan)

A laser rangefinder for forestry that measures the height and distance of trees, and other objects. Utilizing the same laser ranging technology as the golfer’s laser rangefinder COOLSHOT series, it realizes rapid measurement response.

2023

2023

NIKKOR Z 180-600mm f/5.6-6.3 VR super-telephoto zoom lens is marketed

A super-telephoto zoom lens that offers superior agility and outstanding operability. The broad range of focal lengths allows users to enjoy shooting a wide variety of scenes and subjects all with this single lens.

2023

2023

SLM Solutions Group AG (now, Nikon SLM Solutions AG) becomes a wholly owned subsidiary of Nikon Corporation

2023

2023

Nikon’s riblet film adopted on the ANA Future Promise Prop aircraft

Riblet processing is a way of forming structures that emulate shark skin on a surface in contact with fluid, using laser and microfabrication technology. By applying film with this processing to the surfaces of an aircraft, it is expected to reduce the friction drag caused by irregular airflow and improve energy efficiency — contributing to enhanced aircraft fuel efficiency and reduced CO2 emissions.

2023

2023